Heavy-load crossed guide rail shear type slide block

A technology of cross guide rails and sliders, which is applied in the field of track transmission, can solve the problems of small load, inability to intersect the guide rails, and fail to meet the requirements of the motion track, and achieve the effect of strong load capacity and guaranteed sliding stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

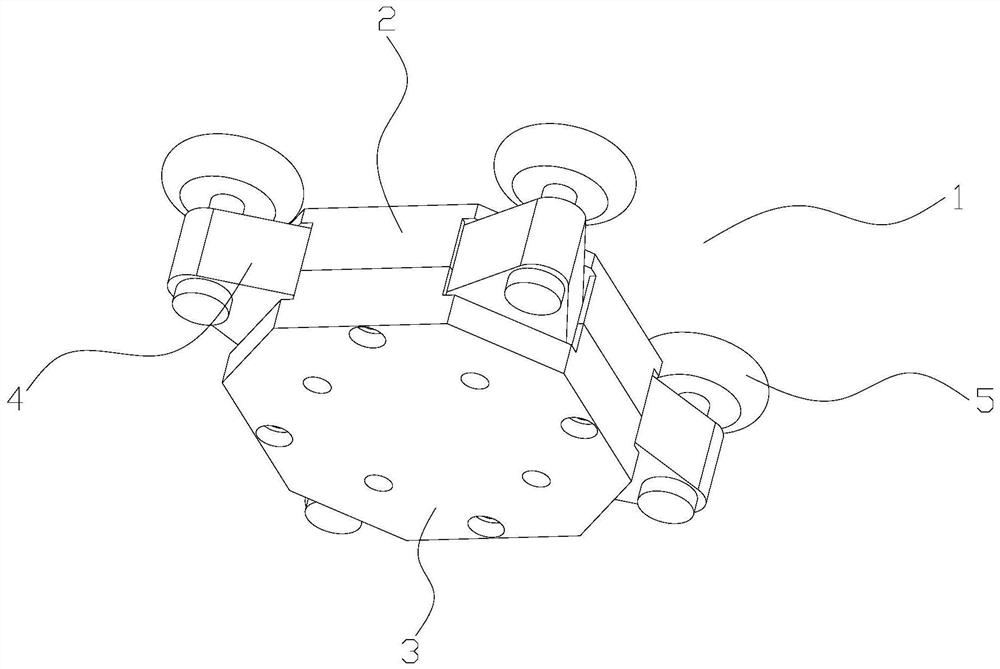

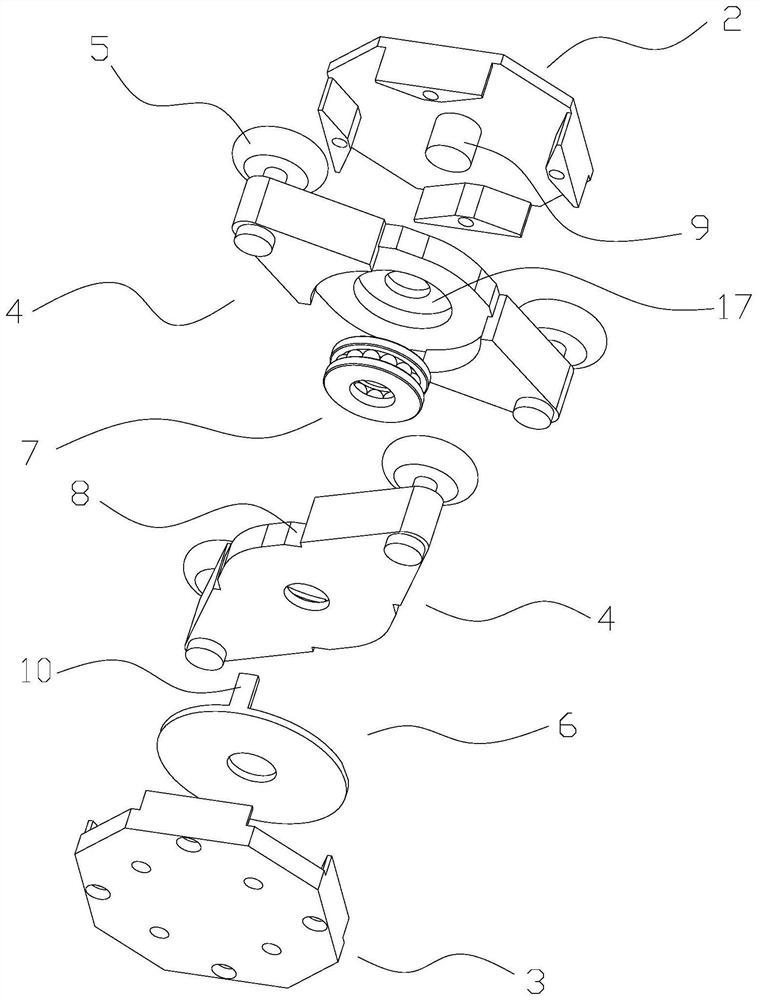

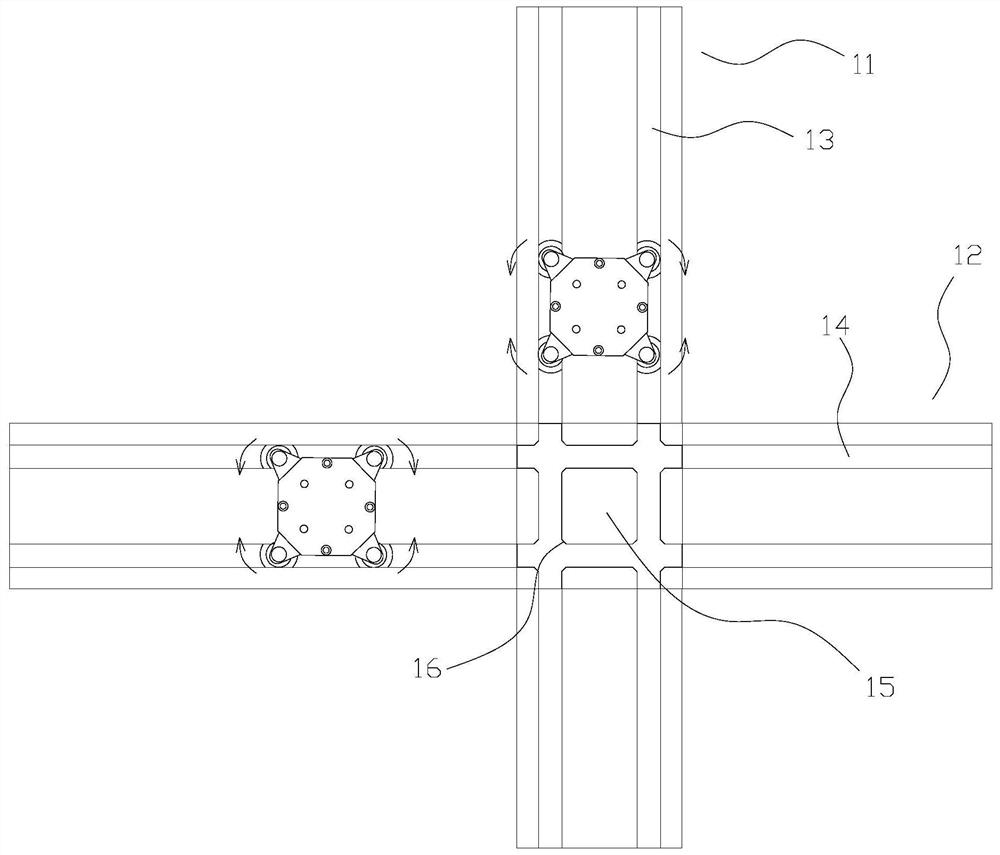

[0035] See figure 1 and image 3 , The present invention provides a heavy-duty cross-rail scissor slider, which includes a sliding block 1 and a longitudinal rail 11 and a horizontal rail 12 that are crossed; wherein, the sliding block 1 includes two scissor members 4 and a bottom slider body 2. The surface slider body 3, the elastic member 6 and the guide wheel 5; the scissor members 4 are cross-hinged with the center as the intersection point, and the ends of the two scissor members 4 are pivotally connected to the bottom side of the sliding block 1. Out of the guide wheel 5; the elastic member 6 is installed between the scissor members 4 to make the two scissor members 4 elastically reverse swing; the bottom slider body 2 is fastened to the bottom side of the two scissor members 4, The surface slider body 3 is buckled on the front of the two scissor members 4, and the surface slider body 3 and the bottom slider body 2 are fixedly connected to each other, and the middle part ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com