Fluorescent sensing technology-based trace explosive detector propelling analysis structure

A fluorescence sensing and detector technology, used in material analysis, fluorescence/phosphorescence, instruments, etc. by optical means, can solve the problems of high temperature, poor heat dissipation performance, large space, etc., to ensure rapid heating capability. , to ensure sliding stability and improve the effect of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in further detail below in conjunction with the accompanying drawings.

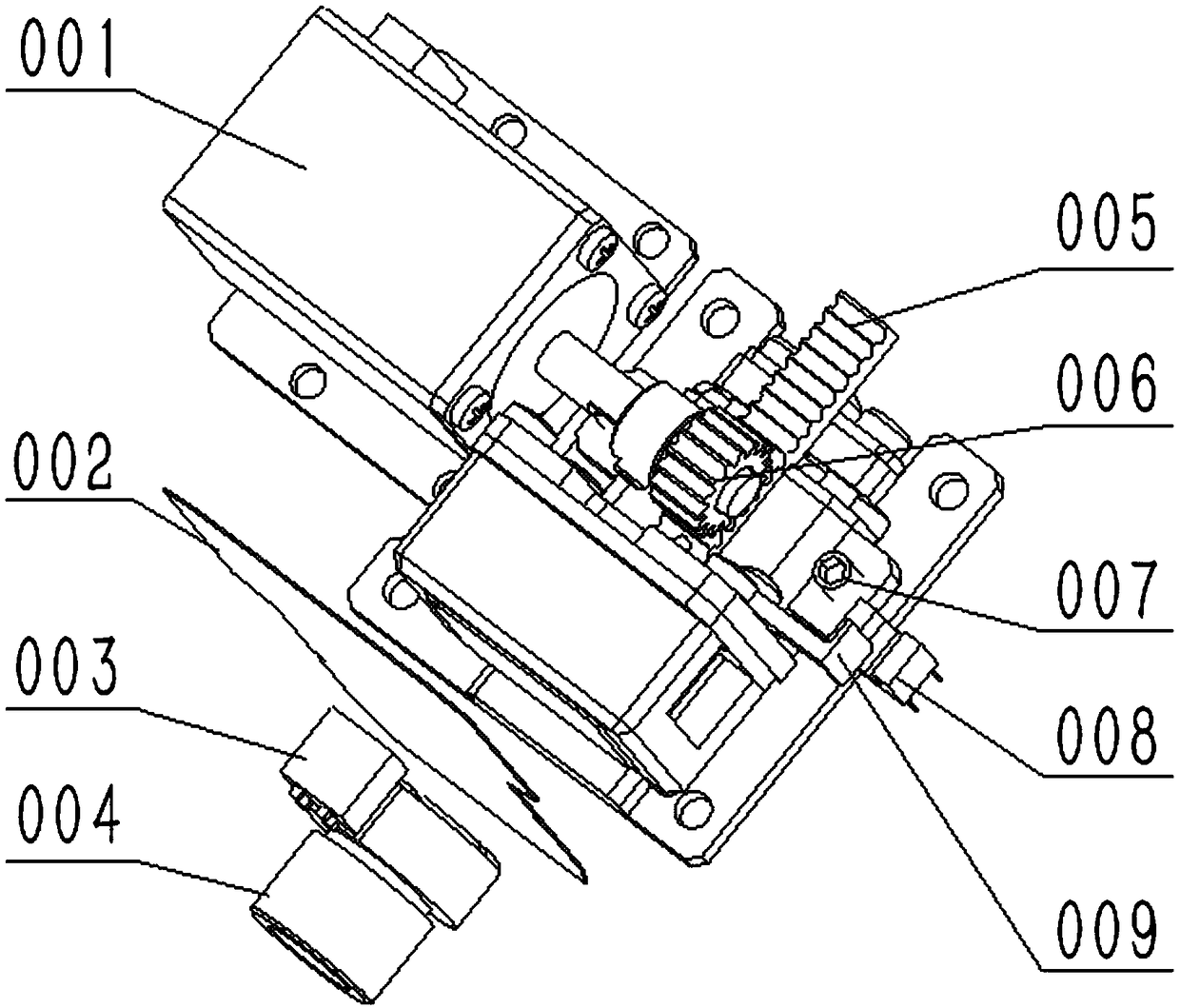

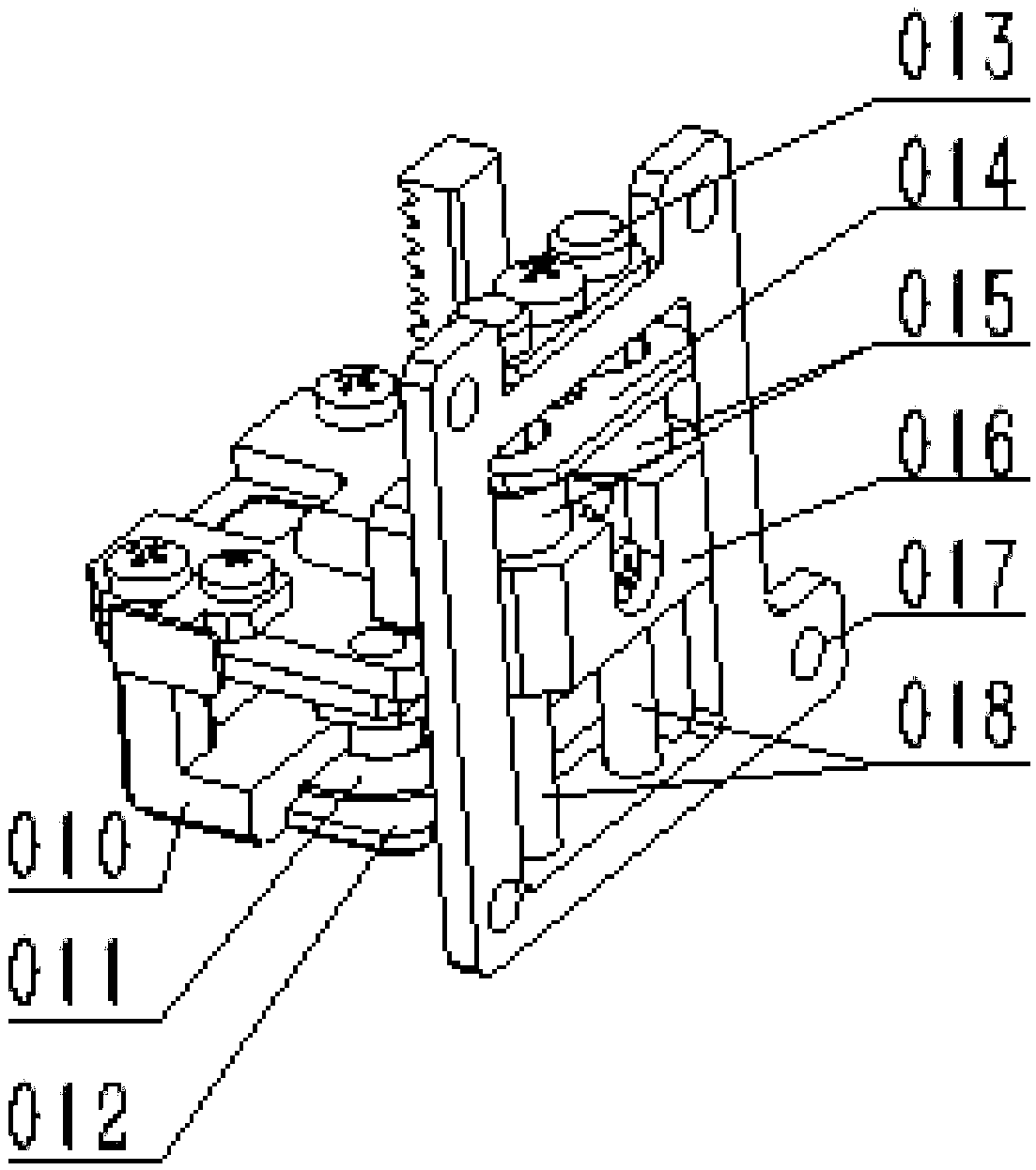

[0024] Such as figure 1 with figure 2 As shown, a propulsion structure of a trace explosive detector based on fluorescent sensing technology includes an analysis device and a sample delivery device. The sample delivery device includes a support base plate 017, and a sample delivery block 016 is slidably arranged on the support base plate 017. The supporting base plate 017 is also provided with a stepping motor 001, and the sample delivery block 016 is provided with a rack 005 extending along its own sliding direction. A heating device for heating and an abutment block 010 opposite to the analysis device are provided; the analysis device includes a sampling analysis head 004 and a scattering photoelectric sensor 003 for controlling the movement of the stepping motor 001. When in use, the user puts the sampling piece 002 is placed on the abutment block 010, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com