Oil stain cleaning equipment with waste oil recovery function

A technology for cleaning equipment and oil recovery, which is applied in the direction of cleaning methods using liquids, cleaning methods using tools, cleaning methods and utensils, etc., which can solve problems such as inability to clean oil stains and decline in the cleaning effect of range hood oil stains, so as to avoid shedding Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

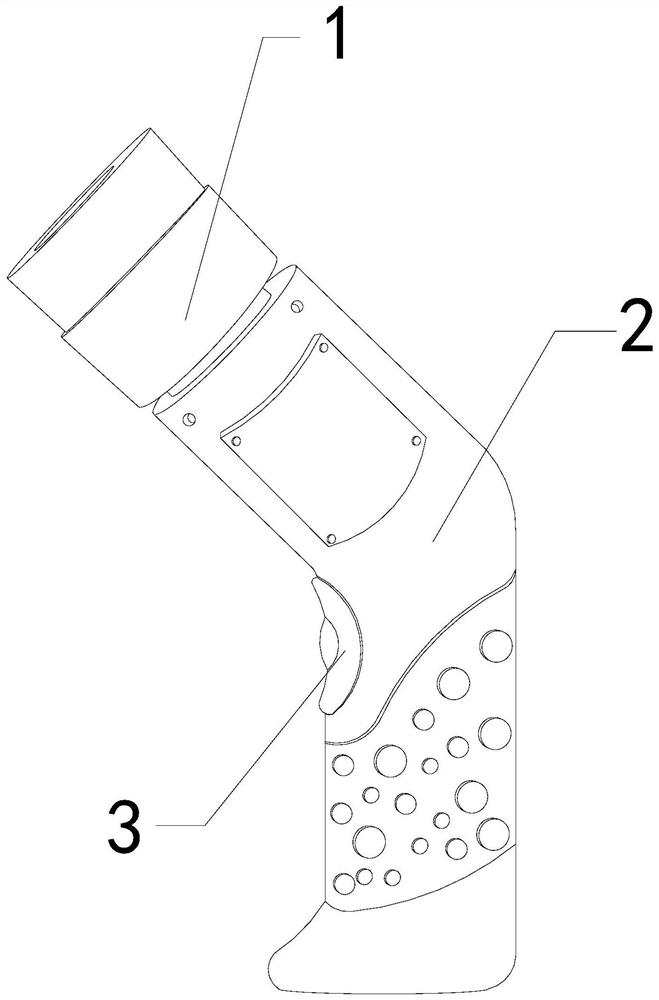

[0026] For example figure 1 -example Figure 5 Shown:

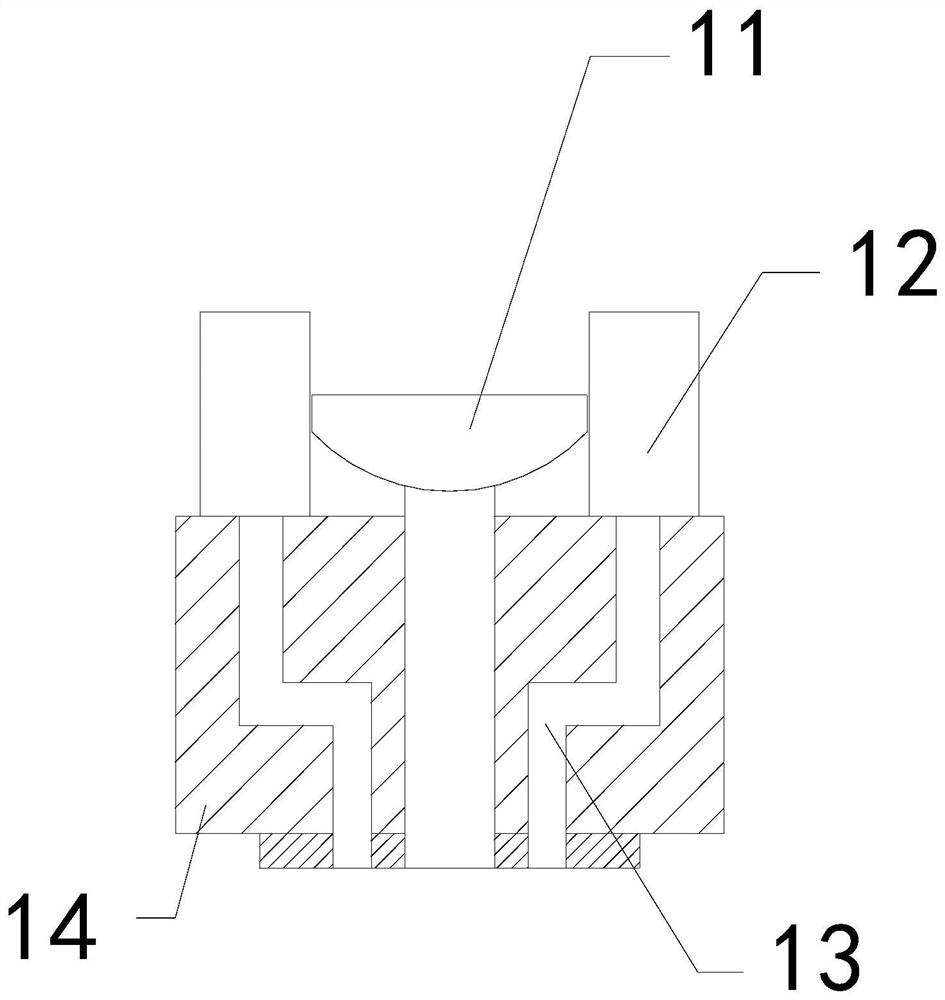

[0027] The present invention provides an oil cleaning device with the function of recycling waste oil. The upper end of 2 is movably engaged; the brush head 1 includes an oil guide plate 11, a brush 12, a liquid guide cavity 13, and a plate body 14. The oil guide plate 11 is embedded in the inner center of the plate body 14, and the hair The brush 12 is installed at the upper end of the plate body 14 , and the liquid-inducing cavity 13 and the plate body 14 are integrated structures.

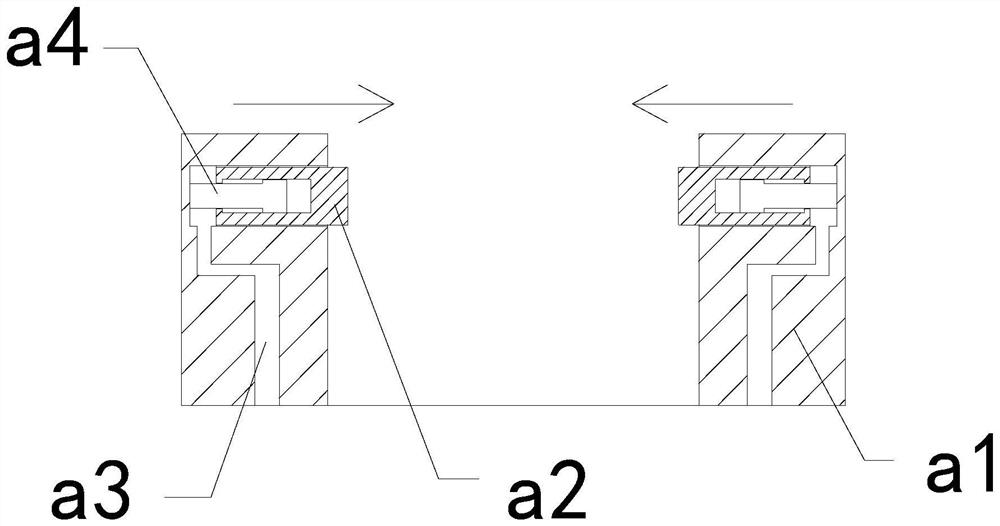

[0028] The brush 12 includes a board surface a1, an overhanging block a2, a through cavity a3, and a fixing rod a4. The overhanging block a2 is movably engaged with the fixing rod a4, and the through cavity a3 runs through the board surface. At the inner position of a1, the fixing rod a4 and the board surface a1 are an integrated structure, and there are two overhanging blocks a2, which are evenly distributed on the left and right sides ...

Embodiment 2

[0034] For example Image 6 -example Figure 8 Shown:

[0035] The movable plate b2 includes a lifting plate b21, a middle connecting rod b22, an elastic sheet b23, and a plate b24. The lifting plate b21 is embedded in the upper end position of the middle connecting rod b22, and the middle connecting rod b22 and the plate b24 are movable. The elastic piece b23 is installed between the middle connecting rod b22 and the plate b24. The reverse thrust generated by the cleaning liquid on the lifting plate b21 when the plate b24 slides down and resets can make the lifting plate b21 cooperate with the middle connecting rod b22. It slides upwards along the plate b24, so that the lifting plate b21 will not immediately bring down the oil stains.

[0036] Wherein, the lifting plate b21 includes an extrusion port c1, an upper plate c2, a bottom plate c3, and a liquid pipe c4. The extrusion port c1 and the upper plate c2 are an integrated structure, and the upper plate c2 is embedded in ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap