Casting forming process for pump body aluminum alloy end cover

A technology of casting and aluminum alloy, which is applied in the field of parts cleaning, can solve the problems of poor cleaning effect of the side wall and bottom wall of the alloy end cap, potential safety hazards, time-consuming and labor-intensive problems, etc., to reduce the stickiness of mud, reduce potential safety hazards, The effect of enhancing the cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways defined and covered by the claims.

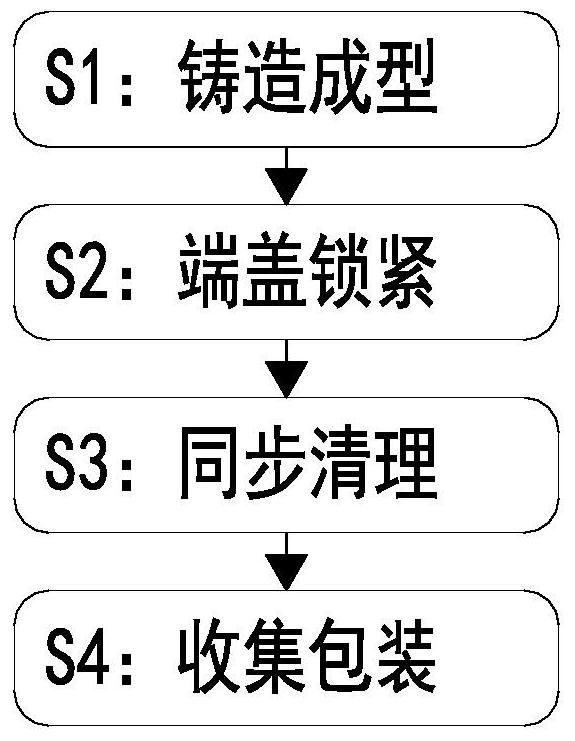

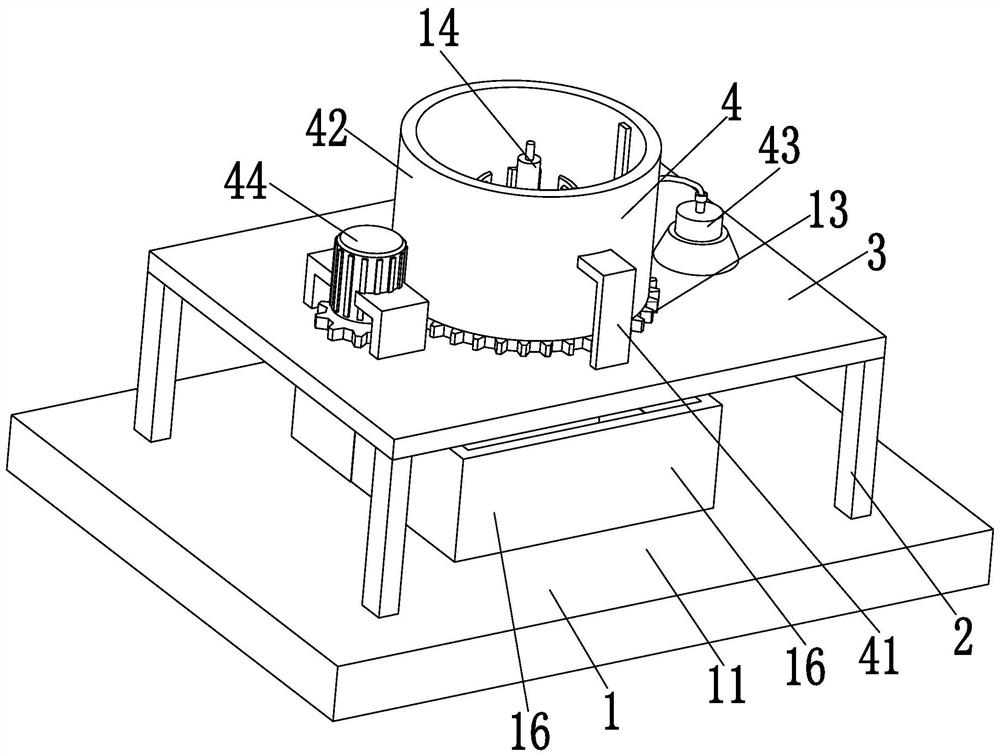

[0040] like Figure 1 to Figure 11 As shown, a pump body aluminum alloy end cover casting molding process uses a pump body aluminum alloy end cover casting molding machine: the machine includes a fixed base 1, a support rod 2, a fixed bottom plate 3 and a cleaning device 4. The upper end of the fixed base 1 described above is evenly equipped with support rods 2 close to the four corners, the upper end of the support rods 2 is connected with a fixed base plate 3, and the fixed base plate 3 is provided with a cleaning device 4.

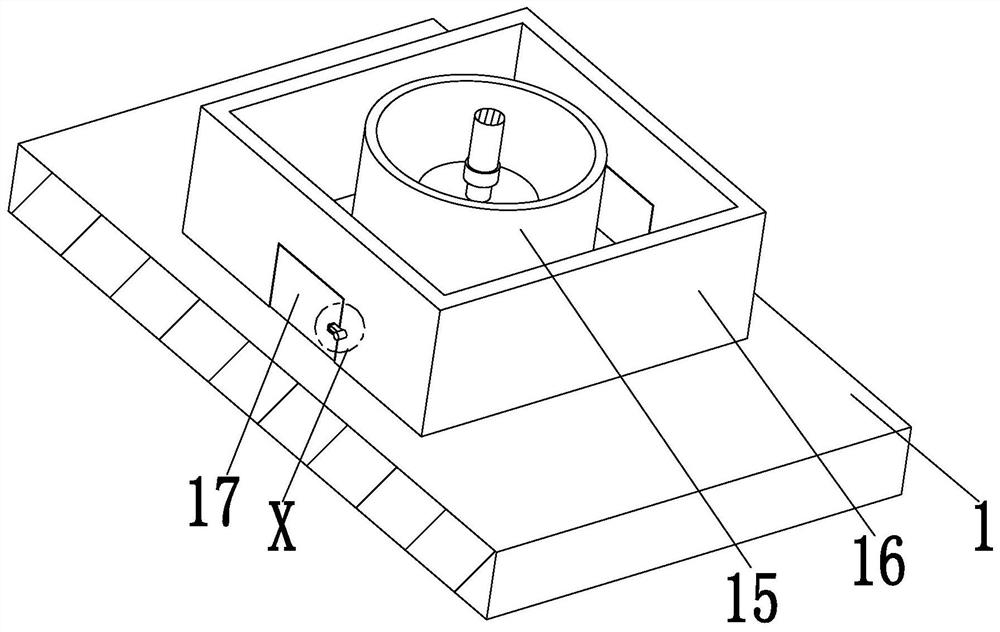

[0041] The fixed base 1 includes a fixed bottom plate 11, a drive motor 12, a transmission mechanism 13, a locking mechanism 14, an annular partition 15, a storage tank 16, a rotating plate 17, an L-shaped locking block 18 an...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap