Efficient injection molding mold opening assembly line

An assembly line, high-efficiency technology, applied in the field of high-efficiency injection mold opening line, can solve the problems of redundant bumps, troubles, dripping, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

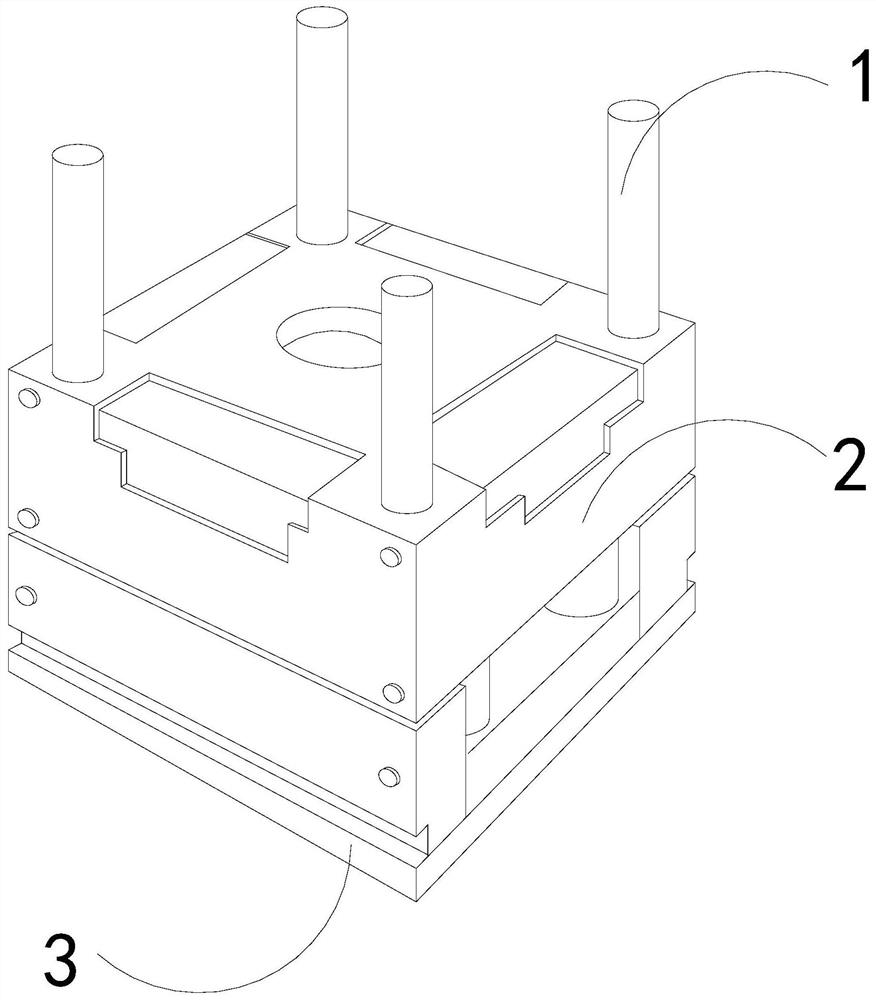

[0026]As for examplefigure 1 -exampleFigure 5 Shown:

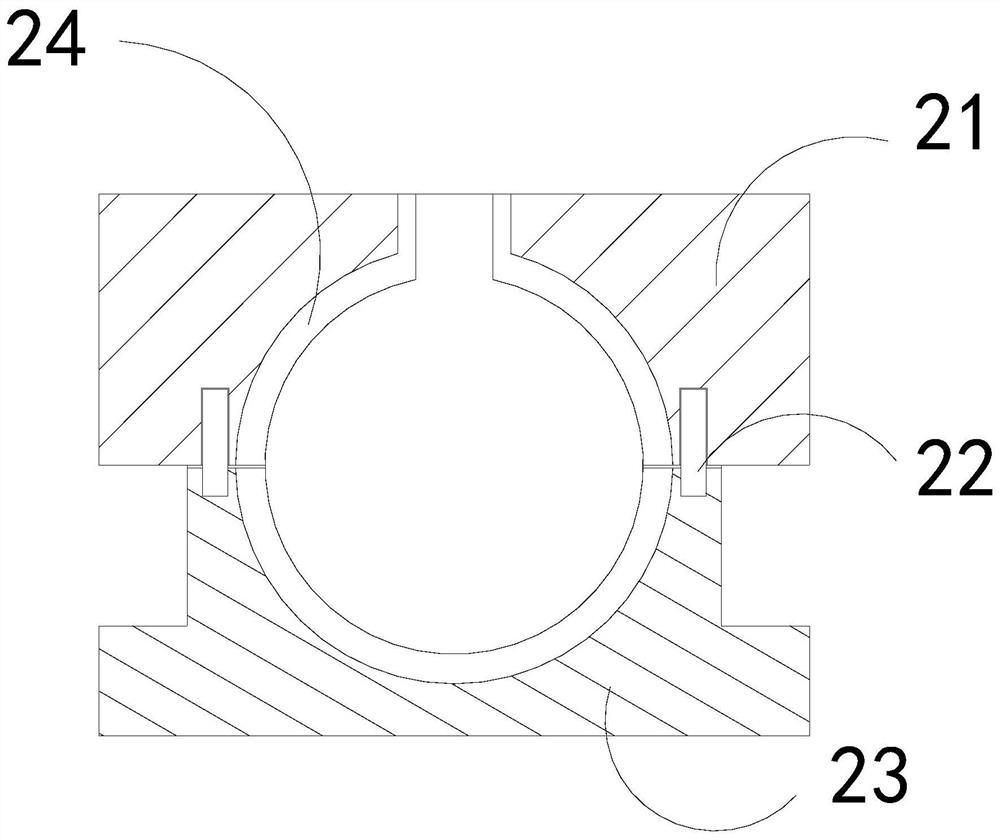

[0027]The present invention provides a high-efficiency injection mold opening line. The structure includes an adapter rod 1, a mold 2, and a base 3. The adapter rod 1 is embedded in the upper end position of the mold 2, and the mold 2 and the base 3 are an integrated structure; The mold 2 includes an upper mold 21, a connecting rod 22, a lower mold 23, and an inner cavity 24. The upper mold 21 is connected to the upper end of the lower mold 23 through the connecting rod 22, and the inner cavity 24 is installed in Between the upper connecting mold 21 and the lower connecting mold 23.

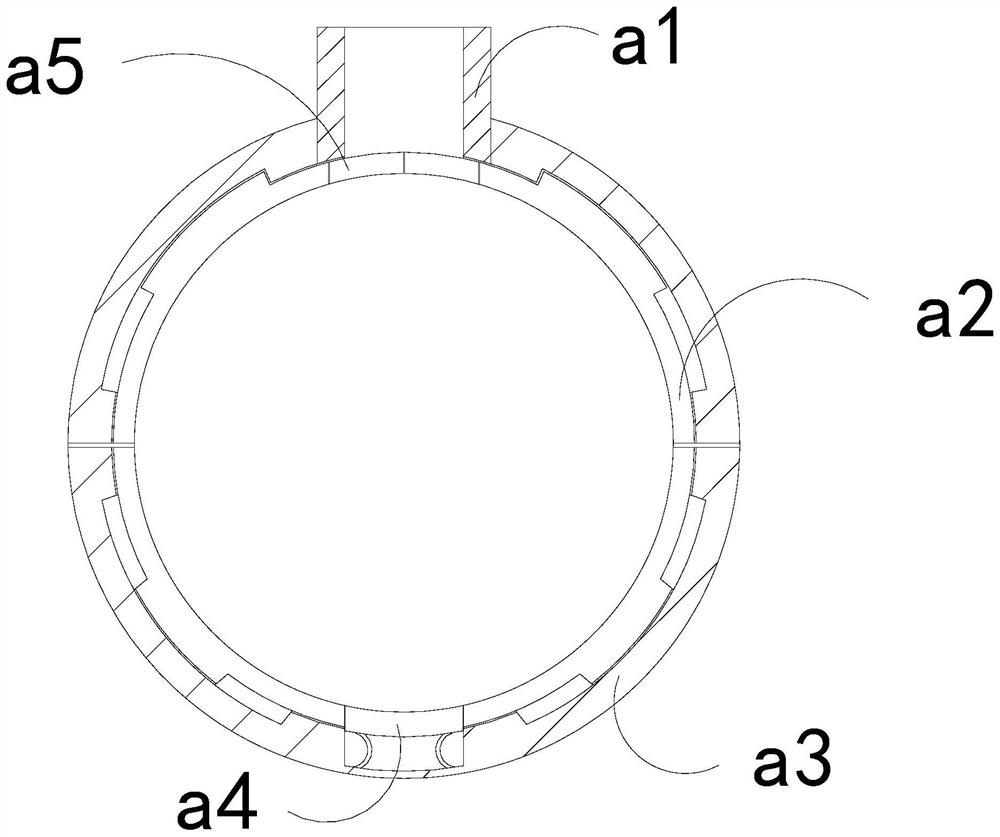

[0028]Wherein, the inner cavity 24 includes a feed pipe a1, a bearing plate a2, an outer ring a3, a squeezed block a4, and a contact plate a5. The feed pipe a1 is embedded in the middle of the upper end of the outer ring a3. The bearing plate a2 is movably engaged with the inner side of the outer ring a3, the squeezed block a4 is in clearance fit with th...

Embodiment 2

[0034]As for exampleFigure 6 -exampleFigure 8Shown:

[0035]Wherein, the feed pipe a1 includes an inner contact plate c1, an outer slide plate c2, and an outer frame c3. The inner contact plate c1 and the outer slide plate c2 are an integrated structure, and the outer slide plate c2 and the inner side of the outer frame c3 are movable cards Together, the outer sliding plates c2 are provided with two, and they are evenly distributed symmetrically on the inner side of the outer frame c3, and the outer sliding plate c2 can be forced to slide upward through the extrusion of the inner contact plate c1 by the plastic.

[0036]Wherein, the inner contact plate c1 includes a force plate c11, a re-elastic strip c12, and a receiving plate c13. The force-receiving plate c11 is movably engaged with the right side of the receiving plate c13, and the re-elastic strip c12 is mounted on the receiving plate c13. Between the plate c11 and the receiving plate c13, the force receiving plate c11 is provided wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com