Device suitable for coiling and forming carbon fiber pipes with different diameters and different wall thicknesses

A carbon fiber technology with different diameters, applied in applications, household appliances, tubular objects, etc., can solve the problem of low efficiency of coiling tubes, achieve the effects of compact molding, ensure applicability, and improve efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

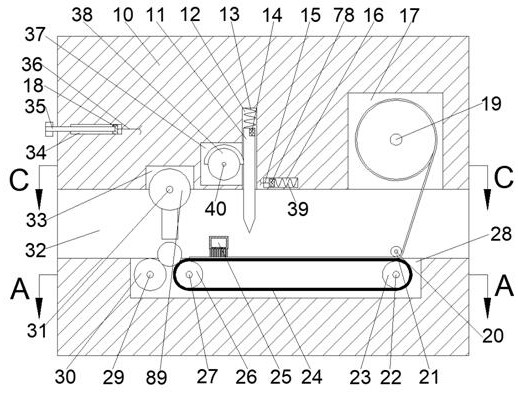

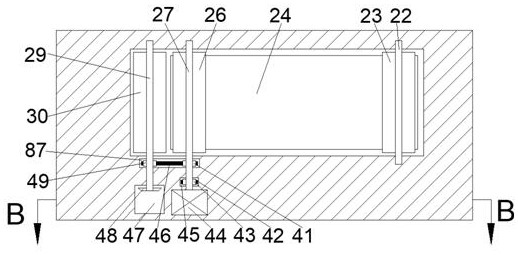

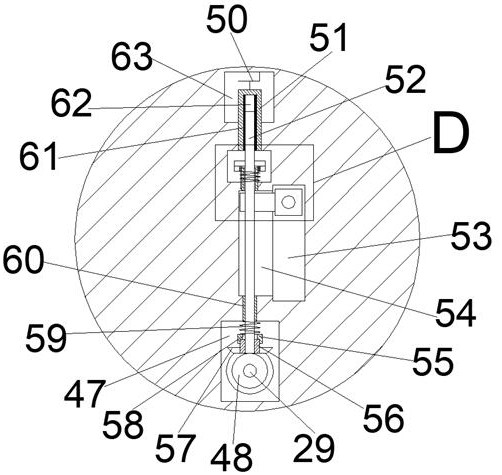

[0018] Combine below Figure 1-5 The present invention is described in detail, wherein, for the convenience of description, the orientations mentioned below are defined as follows: figure 1 The up, down, left, right, front and back directions of the projection relationship itself are the same.

[0019]A device suitable for coil forming of carbon fiber tubes with different diameters and different wall thicknesses described in conjunction with accompanying drawings 1-5 includes a main box body 10, and a feeding cavity 32 is provided through the left and right sides of the main box body 10. The upper side of the feeding chamber 32 is connected with a carbon fiber storage chamber 17, the lower side of the feeding chamber 32 is connected with a conveyor belt chamber 28, and the upper side of the feeding chamber 32 is connected with a tube core pressing wheel chamber 33. The feeding chamber 32 The upper side communicates with a cutting knife sliding chamber 12, the left side of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com