Imaging module and its forming method, lens assembly

An imaging module and imaging technology, applied in electrical components, image communication, color TV components, etc., can solve the problems of insufficient driving capacity and heavy lens modules, and achieve the effects of light weight, low cost and small size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

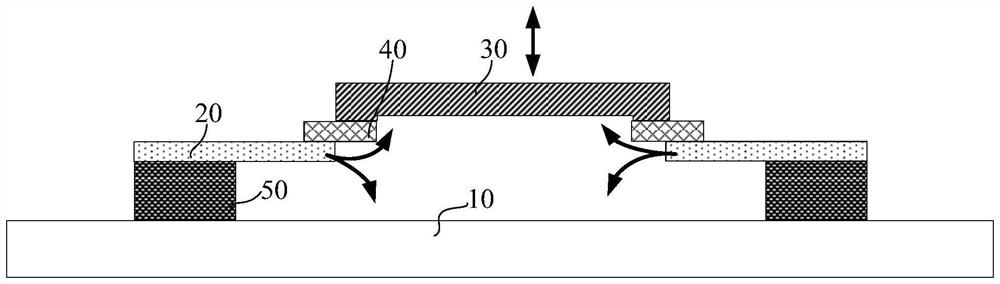

[0063] Such as figure 1 As shown, this embodiment provides an imaging module, including:

[0064] A moved element 30, the moved element 30 is a lens group, a lens sheet or an aperture;

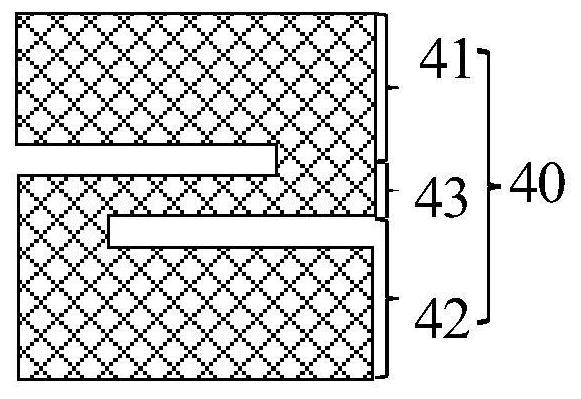

[0065] a flexible connecting piece 40, the connecting piece 40 includes a first end and a second end, the first end is connected to the moved element 30;

[0066] A piezoelectric element 20 comprising a movable end and a fixed end, the movable end is connected to the second end; when the piezoelectric element 20 is powered on, the movable end is tilted upward or downward relative to the fixed end curved to move the moved element 30;

[0067] A support block 50 is used to support and fix the piezoelectric element 20, and the fixed end is fixed to the support block 50;

[0068] The external signal connection terminal is electrically connected with the electrodes in the piezoelectric element 20 .

[0069] Specifically, such as figure 2 As shown, the piezoelectric element 20 includes a piezo...

Embodiment 2

[0096] The difference from Embodiment 1 is that in this embodiment, if Figure 15 As shown, the piezoelectric element 20 is inserted into the support block 50 for fixing, that is, the support block 50 includes a first layer of support blocks 51 and a second layer of support blocks 52 stacked in sequence from bottom to top, The fixed end of the piezoelectric element 20 is fixed between the first support block 51 and the second support block 52 .

[0097] The support block 50 of the present invention is not limited to only including two layers of support blocks, and may also include one layer, three layers, four layers, five layers, etc., as long as the fixed end of the piezoelectric element 20 is inserted into the support block 50 Just fix it.

[0098] see Figure 15 and figure 2 , the external signal connection end includes a third electrical connection end 61 and a fourth electrical connection end 62, the first lead-out end 251 and the second lead-out end 252 are located ...

Embodiment 3

[0103] The difference from Embodiment 1 and Embodiment 2 is that in this embodiment, the moved element 30 is an imaging sensor element.

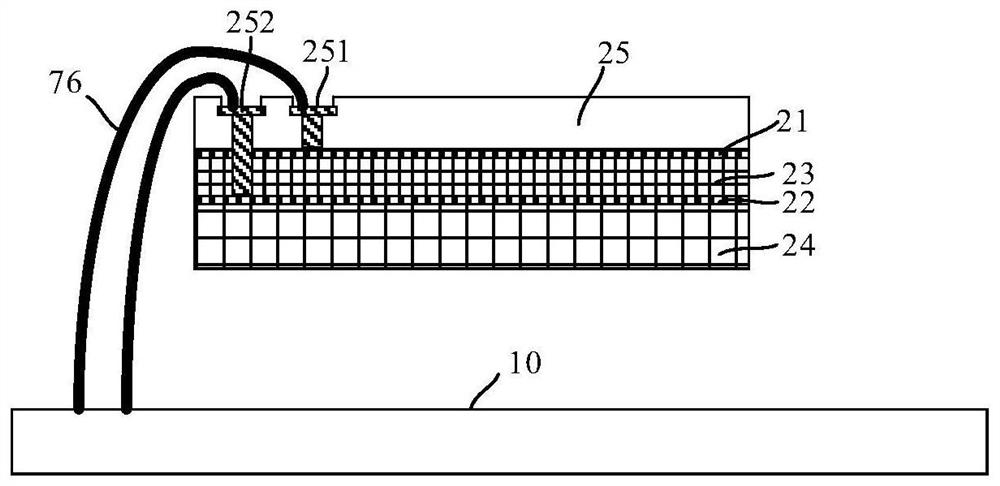

[0104] Such as Figure 18 and Figure 19a As shown, the top surface of the piezoelectric element 20 is also provided with a wiring layer 75, the wiring layer 75 is located in the insulating layer 25, and both ends have a first electrical connection terminal 71 exposing the insulating layer 25 and The fifth electrical connection terminal 74 . The first electrical connection end 71 is closer to the moved element 30 than the fifth electrical connection end 74, the upper surface of the moved element 30 is provided with a second electrical connection end 72, the first electrical connection end 71 and the second electrical connection end 72 are electrically connected through a flexible electrical conductor 73, and then a lead wire 76 is used to electrically connect the fifth electrical connection end 74 to the circuit board 10, so that the circu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com