Variable flow rate valve mechanism and supercharger

A valve mechanism and variable technology, applied in the direction of machines/engines, connecting components, mechanical equipment, etc., can solve the problems of spring washer elasticity deterioration and elasticity deterioration, and achieve the effect of suppressing elasticity deterioration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

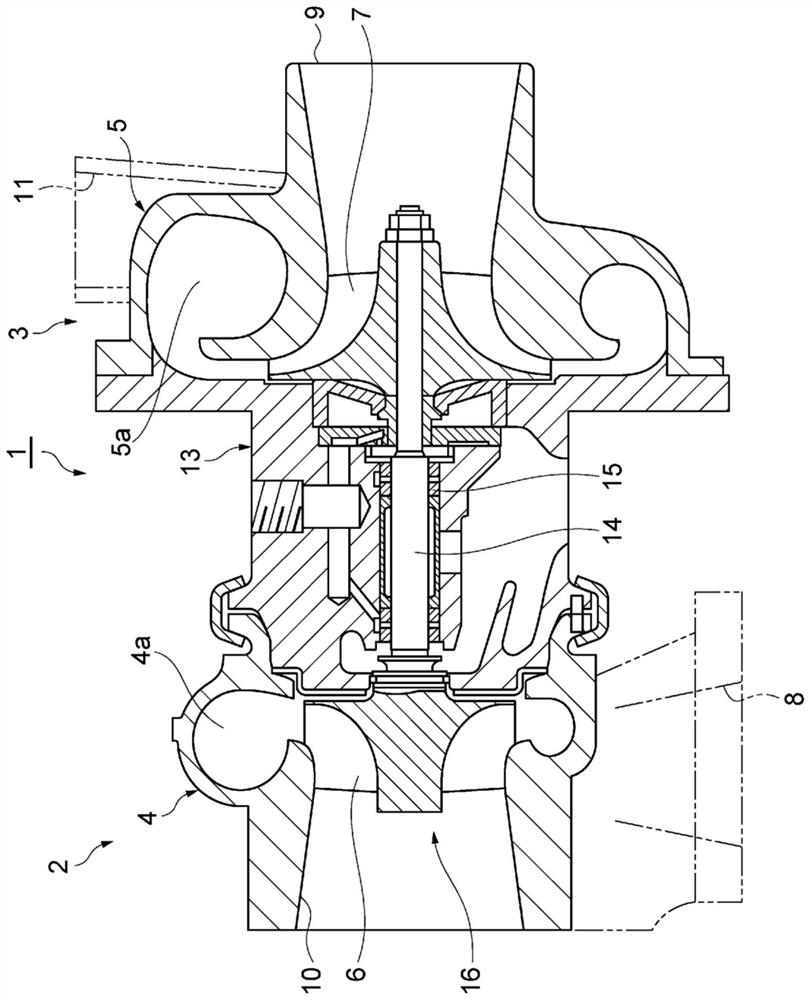

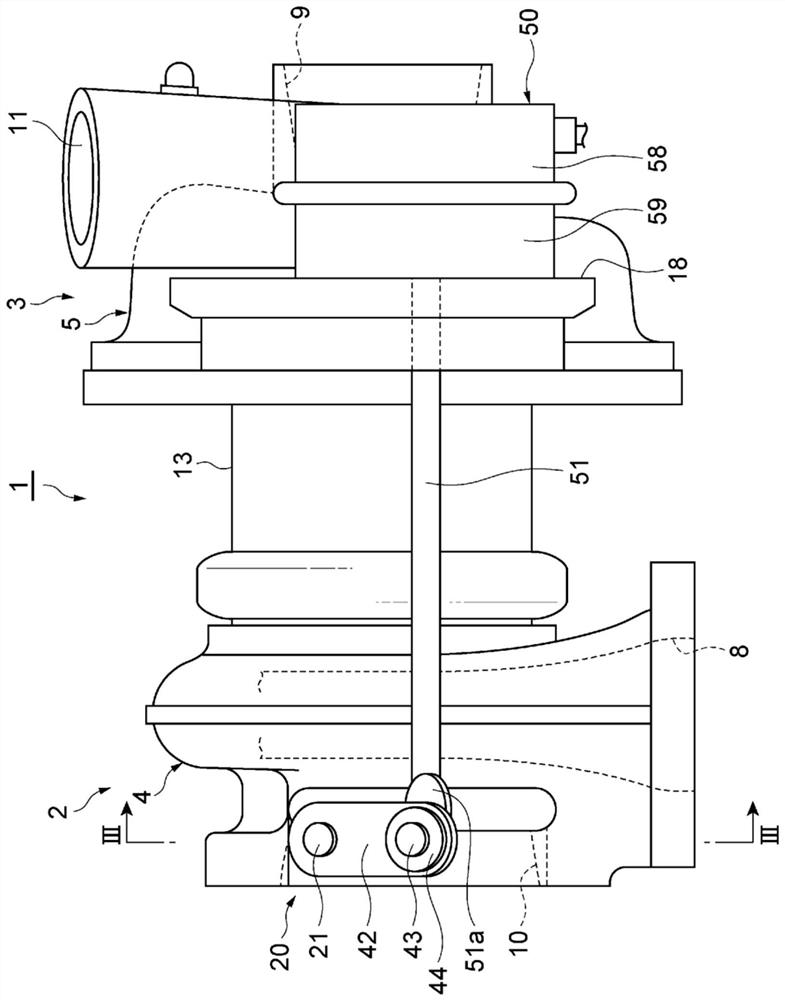

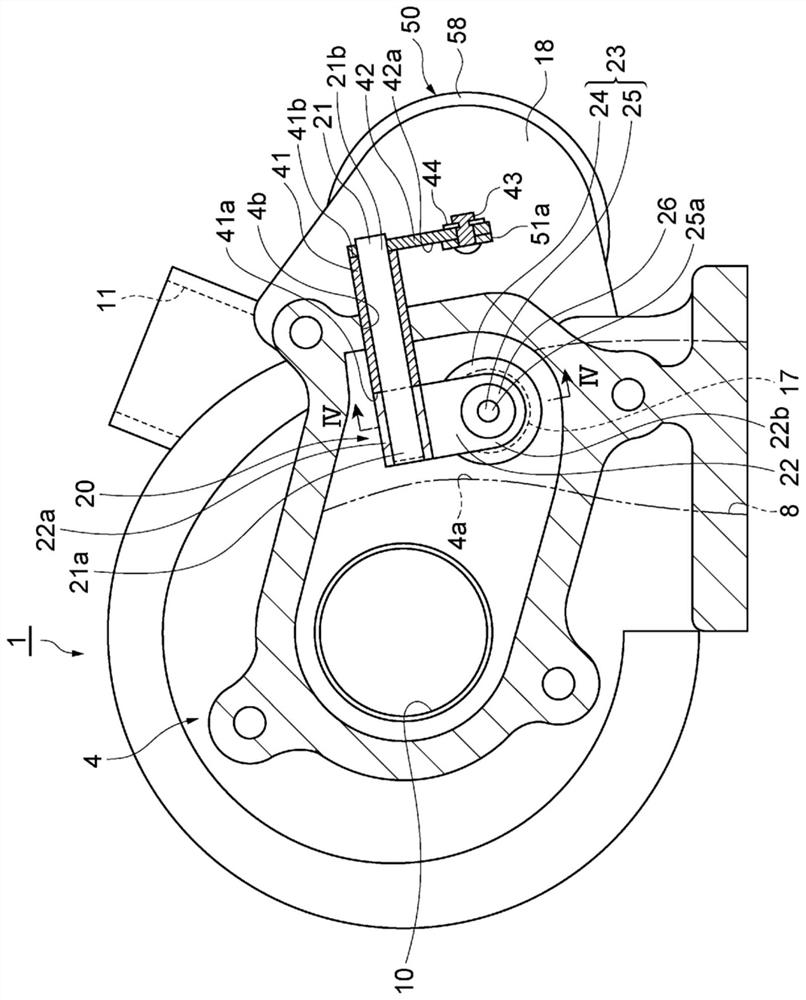

[0020] A variable flow valve mechanism according to one aspect of the present disclosure includes: a valve including a valve body and a valve shaft protruding from the valve body and having an axis; a stopper member fixed to the valve shaft at a position separated from the valve body in the axial direction; A mounting part, which is arranged between the valve body and the stopper, holds the valve together with the stopper; and a spring washer, which is arranged between the stopper and the installation part, or between the installation part and the valve body, and serves as The stopper part or the first part of the valve body is in contact with the second part as the installation part to apply elastic force to the installation part. The spring washer includes an outer peripheral part in contact with either the first part or the second part. Either one of the second member and the second member is formed with an inner surface facing radially inward and facing the outer peripheral...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com