An automatic peanut harvesting device

A harvesting device and automatic technology, which is applied in the direction of harvesters, digging harvesters, agricultural machinery and implements, etc., can solve the problems that the machine design is not comprehensive enough, and can not separate peanuts, rhizomes, peanuts and fruits well, so as to save secondary processing Operation, improve harvesting efficiency, good harvesting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

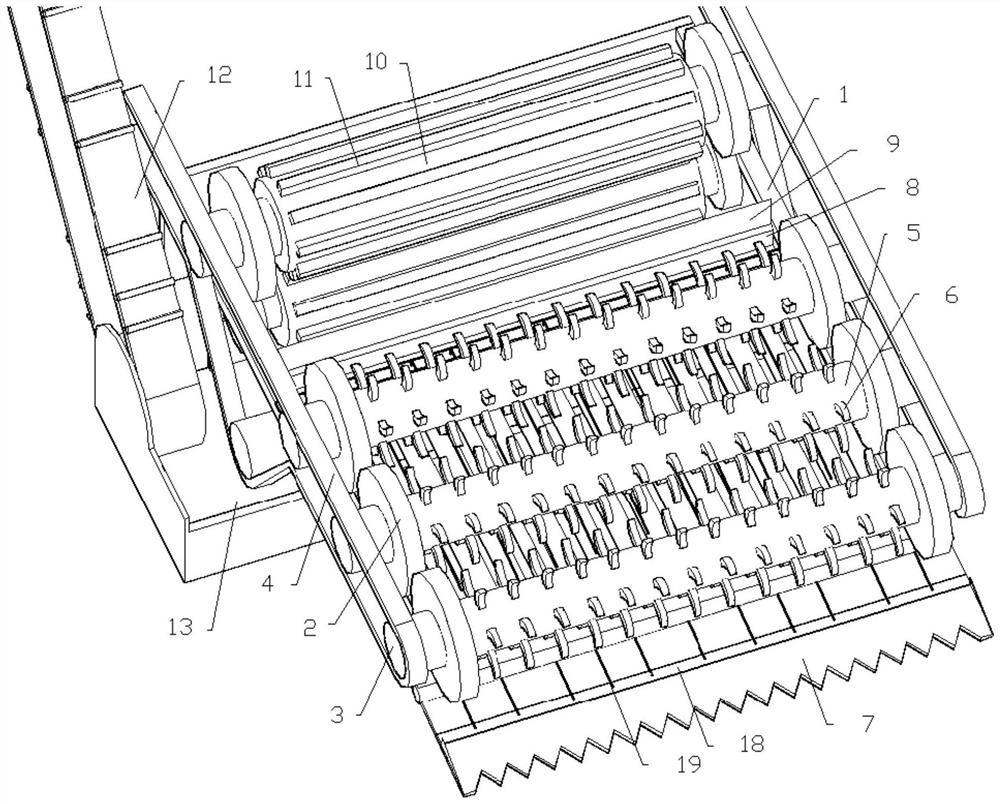

[0016] In order to make the technique for the invention, the creation characteristics, the purpose and efficacy are readily understood, and the present invention will be further illustrated in connection with the specific illustration.

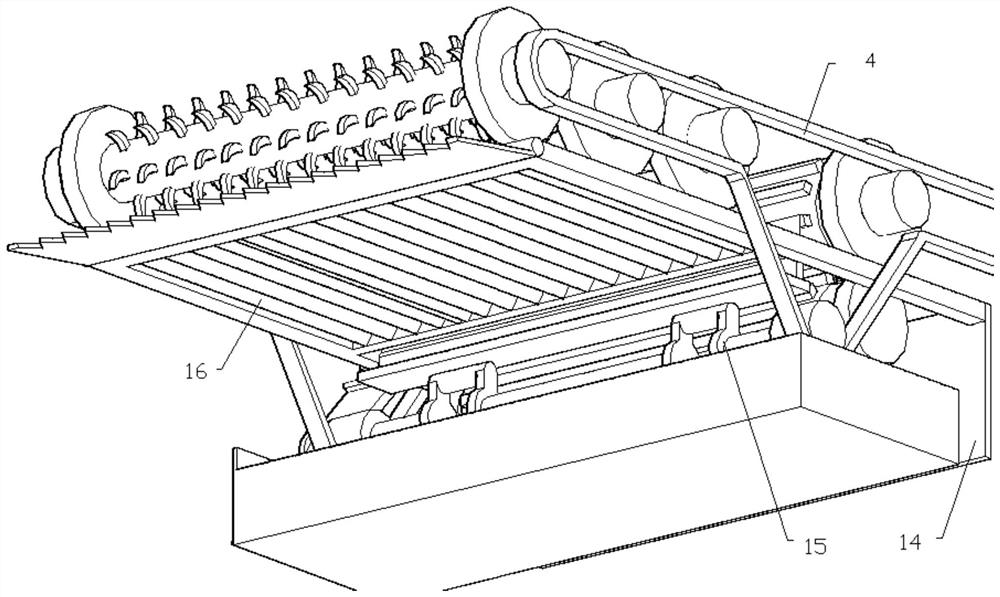

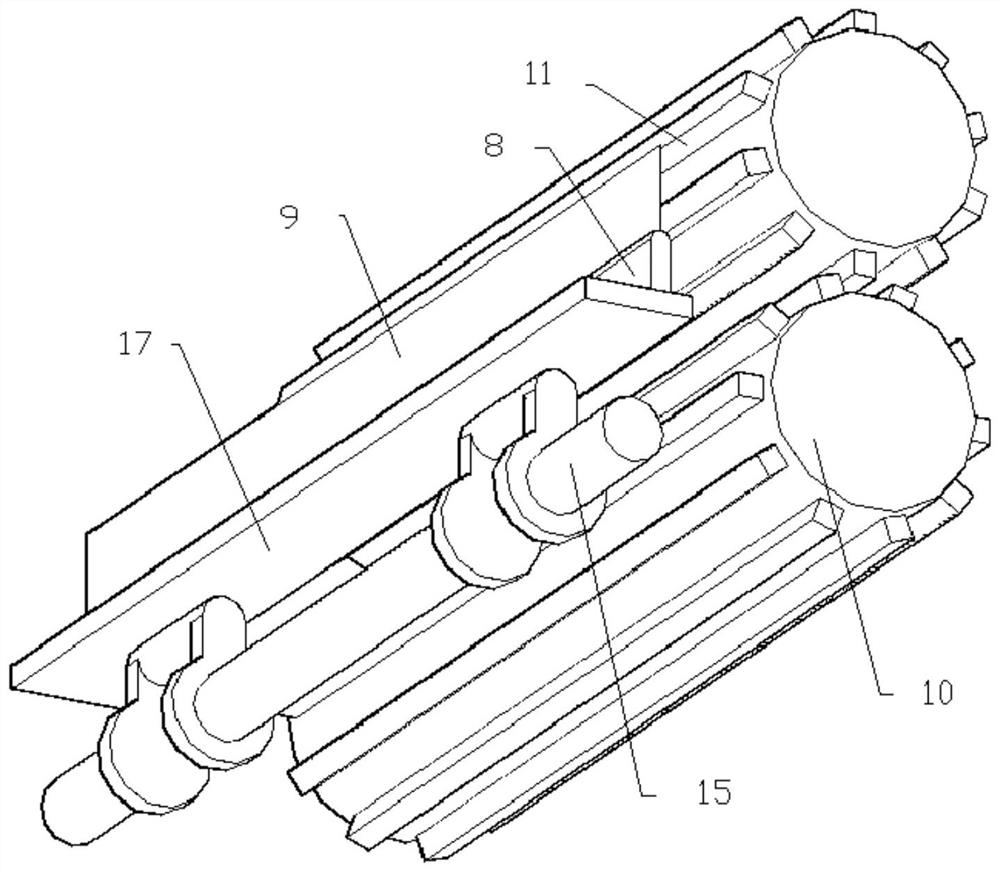

[0017] like Figure 1 to 4 As shown, a peanut automatic harvesting device includes a harvester drive motor, a harway machine, a host holder, and a harvester 1, and the harvester 1 is fixed to the front of the host frame, and the harvester 1 is fixed by the rotation axis. Adjustable excavation shovel 7, digging shovel 7 rear harvesting rack 1 surface opening has a rectangular row pipe, rectangular row water, the rectangular spacing is provided with a plurality of longitudinal interval isometric arrangement triangular grid 16, rectangular row There are several grip rotating rods 5, and both sides of the grip rotating rod 5 are provided on both sides of the grip rotating rods, each of which is provided with several surround distribution portions. Howe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com