Fine milling device used for production and processing of flour and milling method of fine milling device used for production and processing of flour

A fine grinding and flour technology, applied in grain processing, etc., can solve the problems of low grinding efficiency, inconvenient flour processing overall efficiency, material jams, etc., and achieve high grinding efficiency, easy centralized collection, and no material jams.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

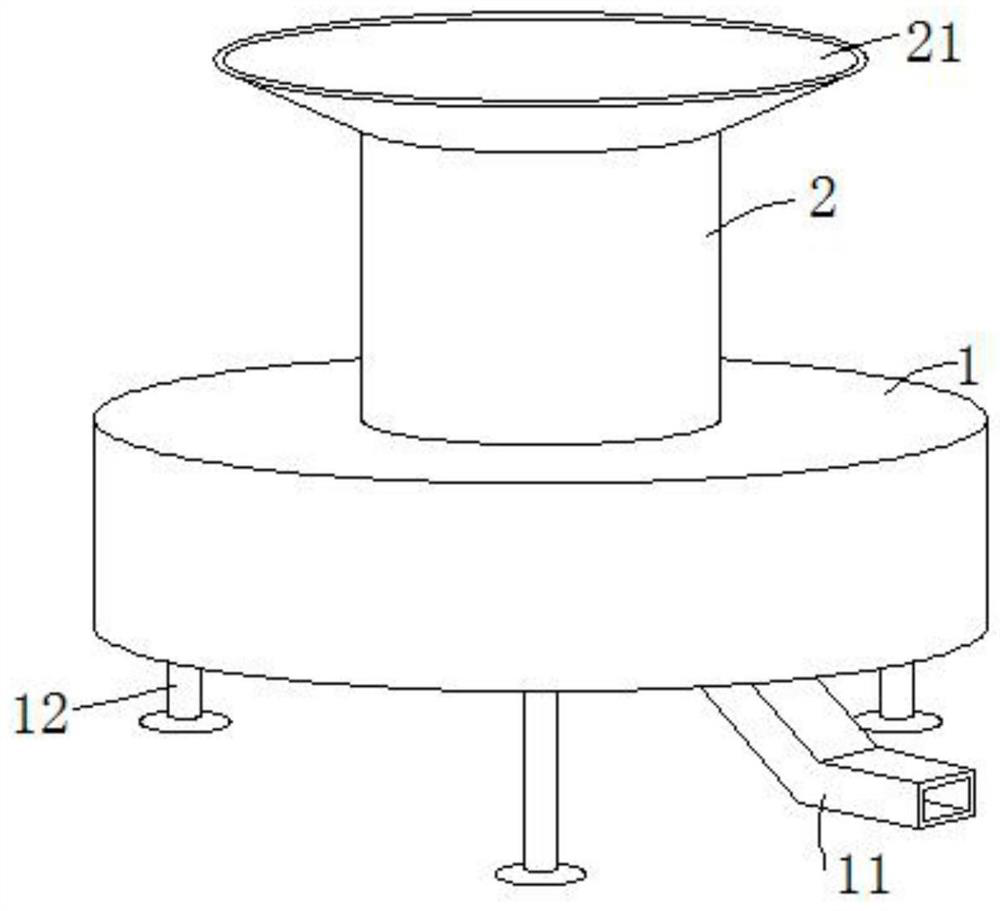

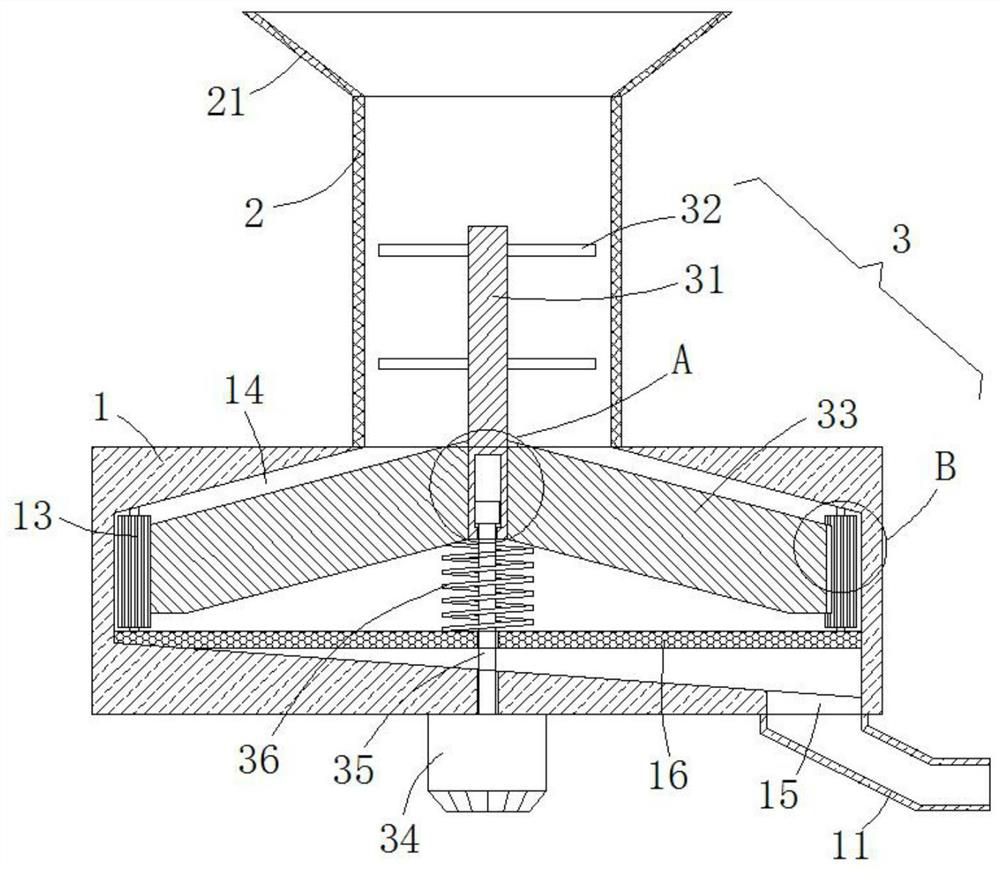

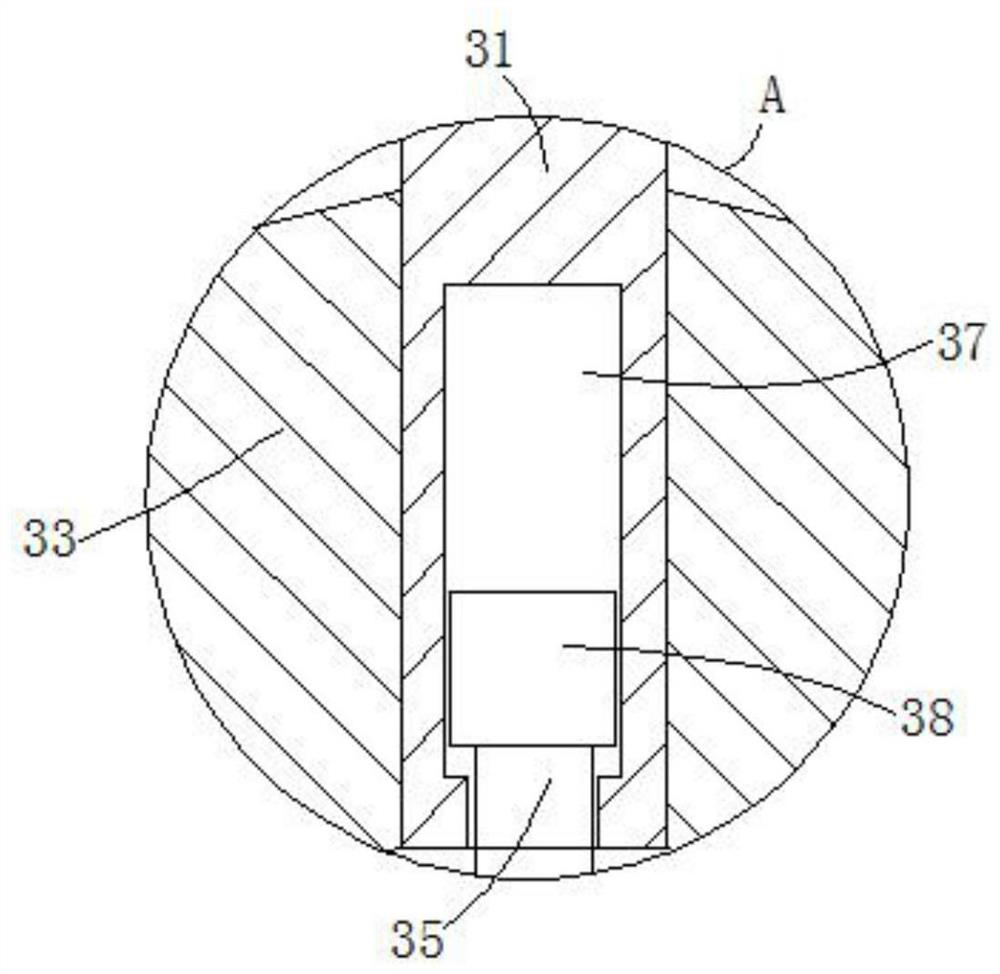

[0028] see Figure 1-5 , the present embodiment provides a fine grinding device for flour production and processing and a grinding method thereof, comprising a grinding seat 1 and a grinding mechanism 3, the edge of the bottom end surface of the grinding seat 1 is vertically provided with several support legs which are evenly spaced in a ring shape 12. Utilize the supporting legs 12 to prop up the entire grinding seat 1. The inner cavity of the grinding seat 1 is provided with a grinding cavity 14, and the bottom end of the grinding cavity 14 is provided with a sieve tray 16, and the edge side wall of the sieve tray 16 is connected to the The radial side walls of the inner cavity of the grinding cavity 14 are seamlessly bonded. The sieve disc 16 here is used for the powder filtration operation after grinding. The sieve disc 16 with different sieve holes is selected according to the requirements of the grinding thickness to meet different grinding requirements. The inner cavity...

Embodiment 2

[0036] see Figure 1-5 , further improvements have been made on the basis of Example 1:

[0037] The bottom end of the grinding cavity 14 is set at an inclination of 35° to the lower right. By setting the bottom end of the grinding cavity 14 at an inclination of 35° to the lower right, it is convenient to slide the ground powder particles to the discharge port 15 along the 35° incline. In order to prevent the ground powder particles from accumulating in the inner cavity of the grinding cavity 14 and cannot be discharged;

[0038] The radial side wall of the stirring shaft 31 is provided with a plurality of stirring rods 32 distributed evenly along the axial direction of the stirring shaft 31, and the stirring rods 32 can be used to stir the wheat grains stuck in the inner cavity of the feed pipe 2, so as to Prevent the phenomenon of material jam.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com