Patents

Literature

73results about How to "Unable to discharge" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

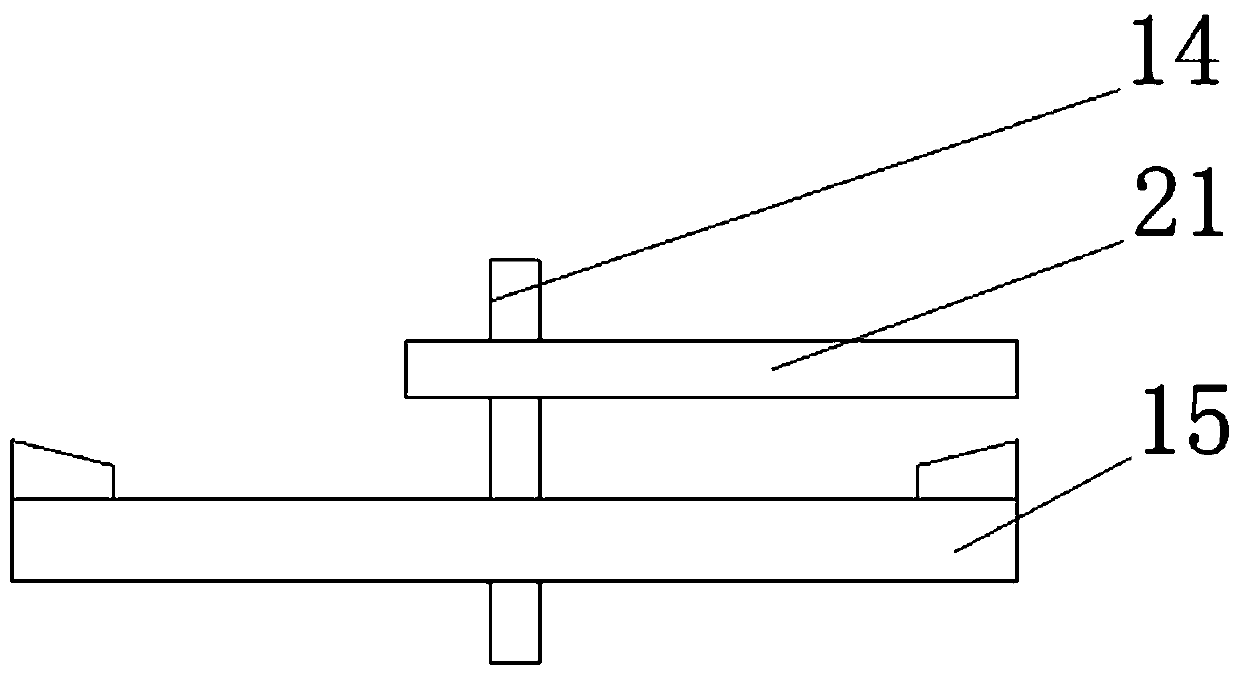

Machining process of hard veneers

InactiveCN105965642AAvoid foamingSmooth leather processingWood treatment detailsLaminationNegative temperatureEngineering

The invention discloses a machining process of hard veneers. After the hard veneers are softened and dried, wood becomes soft, so that veneer splicing machining is smoother and the splicing effect is better in veneer splicing and hotly pressing veneer laminating processes; in the hotly pressing veneer laminating process, a phenomenon that the veneers are foamed can be effectively avoided; an obtained veneer laminated product is subjected to fine machining including paint spraying, fabric process, package and the like to prepare a veneer laminated furniture product; and in a utilization period of positive and negative temperature difference, phenomena that the veneers are cracked and paint is delaminated can be effectively avoided.

Owner:FUJIAN SENYUAN FURNITURE CO LTD

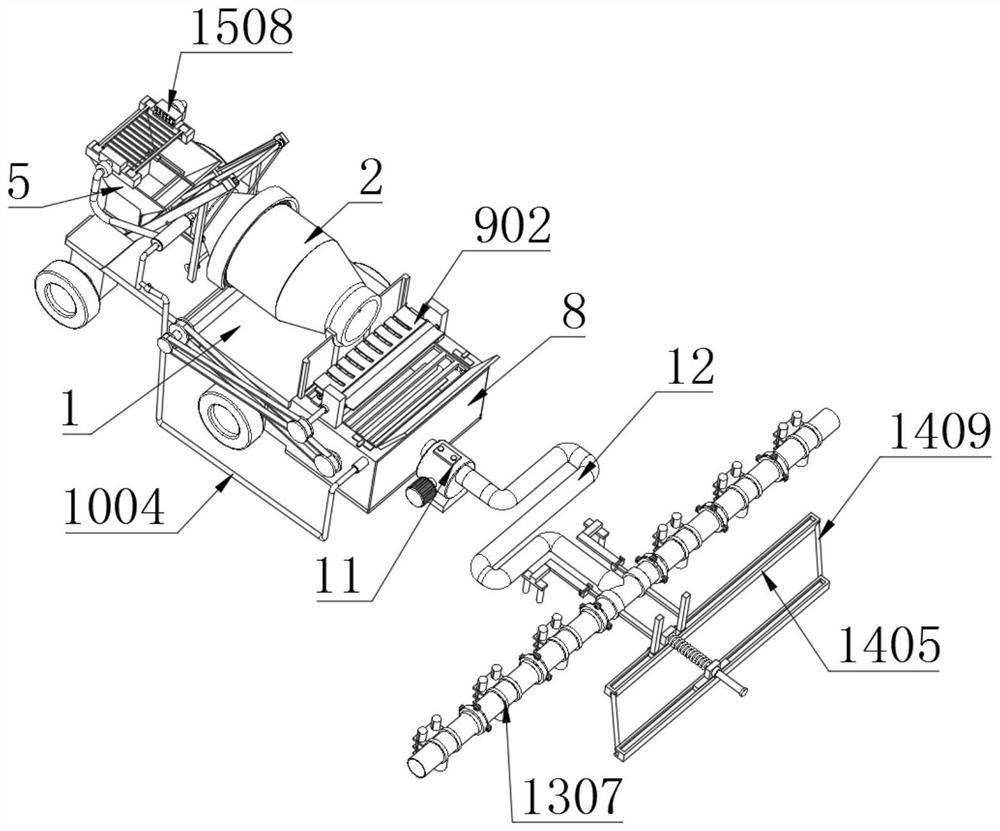

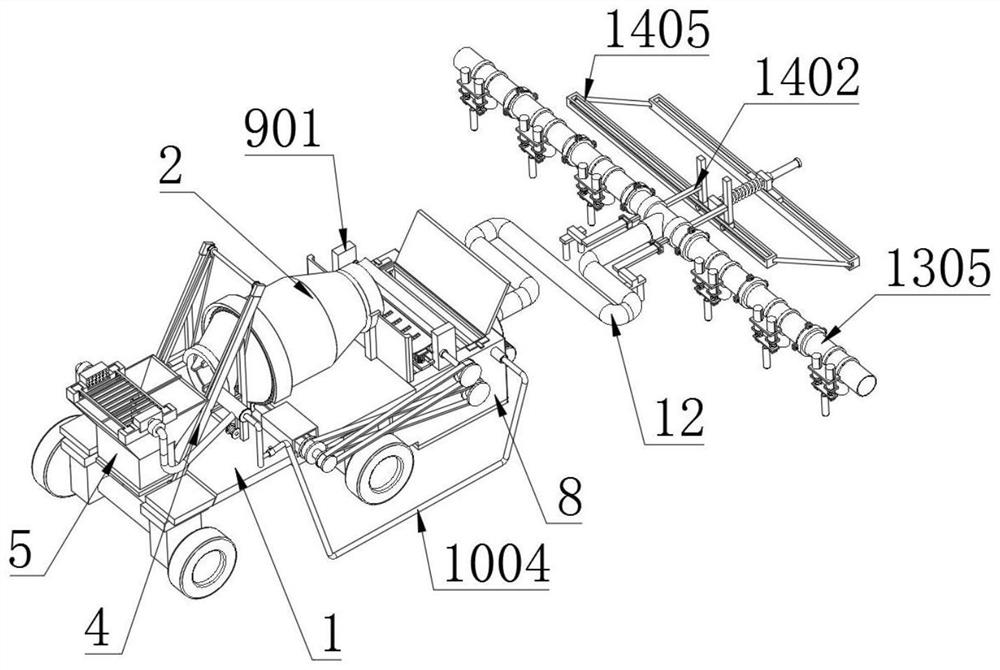

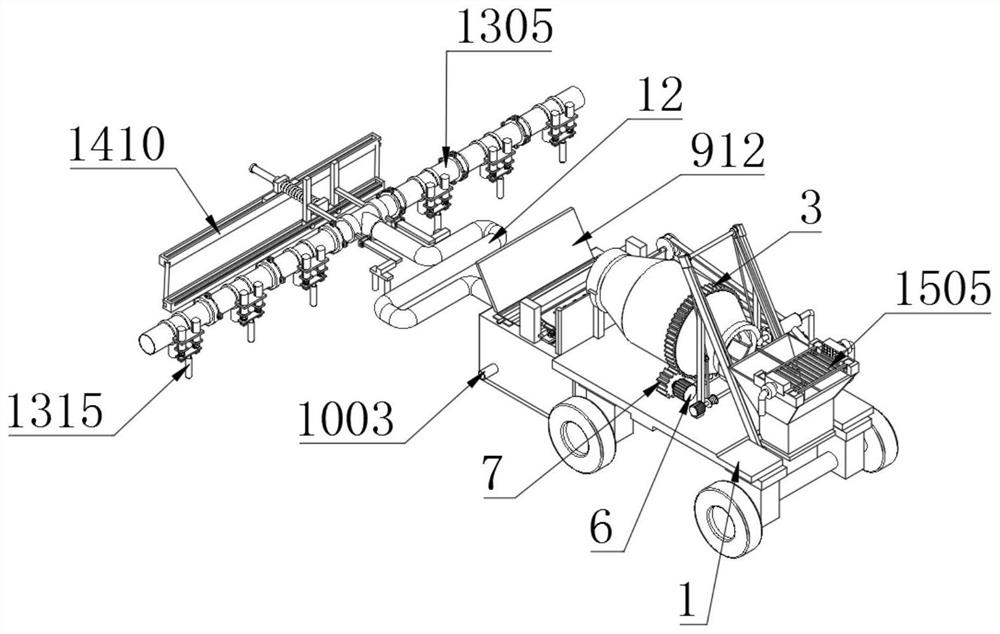

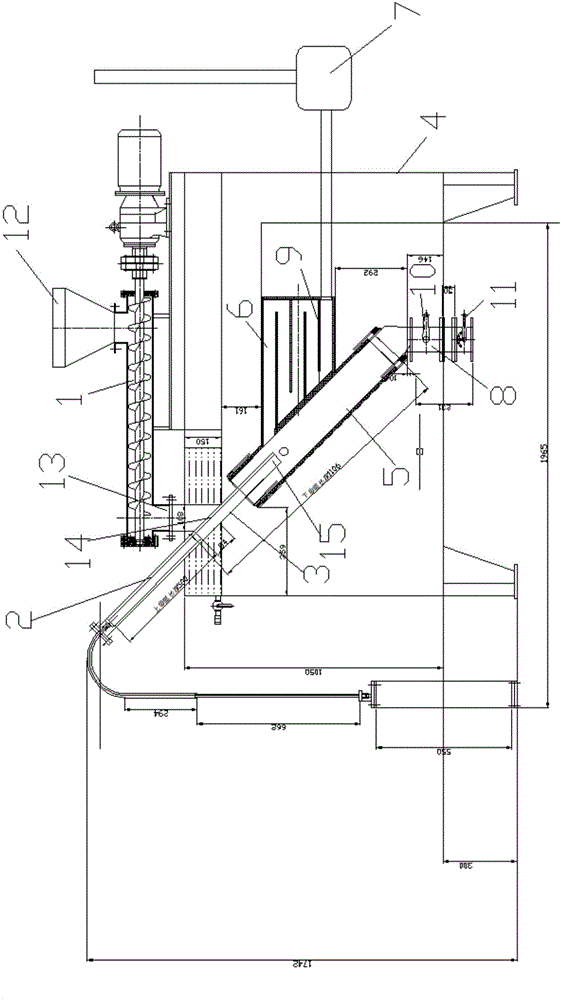

Environment-friendly construction site production pouring device

InactiveCN113279583AIncrease or decrease quantityReduce labor intensityRoads maintainenceBuilding material handlingArchitectural engineeringStructural engineering

The invention discloses an environment-friendly construction site production pouring device. The environment-friendly construction site production pouring device is characterized in that fixing seats are symmetrically and fixedly mounted at the two ends of a main connecting pipe, fastening blocks are fixedly mounted at one ends of the fixing seats in the circumferential direction, fixing bolts are fixedly mounted in the middles of the fastening blocks, connecting branch pipes are fixedly connected to one ends of the fixing seats, and the middles of the bottom ends of the connecting branch pipes are fixedly connected with discharge pipes. The pouring device is provided with a concrete equal-distance and uniform casting mechanism, the connecting branch pipes are additionally arranged at the two ends of the main connecting pipe and are fixedly connected with the main connecting pipe, so that concrete can be discharged along the connecting branch pipes and the discharging pipes, the concrete is provided with a plurality of discharging ports, the positions of the discharging pipes do not need to be manually changed or dragged, it can be guaranteed that concrete is poured at multiple positions at the same time, the discharging pipes can be specifically fixed to the preset pouring position, vibration rods is inserted into the poured concrete in the pouring process, and vibration is conducted on the interior of the just-poured concrete to eliminate bubbles doped in the concrete.

Owner:段云雷

Small microwave fecal treatment device and fecal treatment method

InactiveCN105859089ANo residueUnable to dischargeSpecific water treatment objectivesSludge treatment by pyrolysisFecesMicrowave pyrolysis

The invention discloses a small microwave fecal treatment device and a fecal treatment method. The small microwave fecal treatment device comprises a spiral feeding device, a pushing device, a microwave pyrolysis cavity, a high-temperature pyrolysis cavity, a gas treatment device, a high-temperature fan and a discharging device. Both the high-temperature pyrolysis cavity and the gas treatment device are located in the microwave pyrolysis cavity. Both the spiral feeding device and the high-temperature fan are located outside the microwave pyrolysis cavity. The small microwave fecal treatment device applies a microwave technique to conduct disinfection, deodorization and reduction on excrement and make the excrement meet the requirements, meanwhile has the advantages of being small in occupied area, low in energy consumption, high in efficiency and the like and can be applied to mobile public toilets and high-speed rail public toilets.

Owner:胡恩林 +1

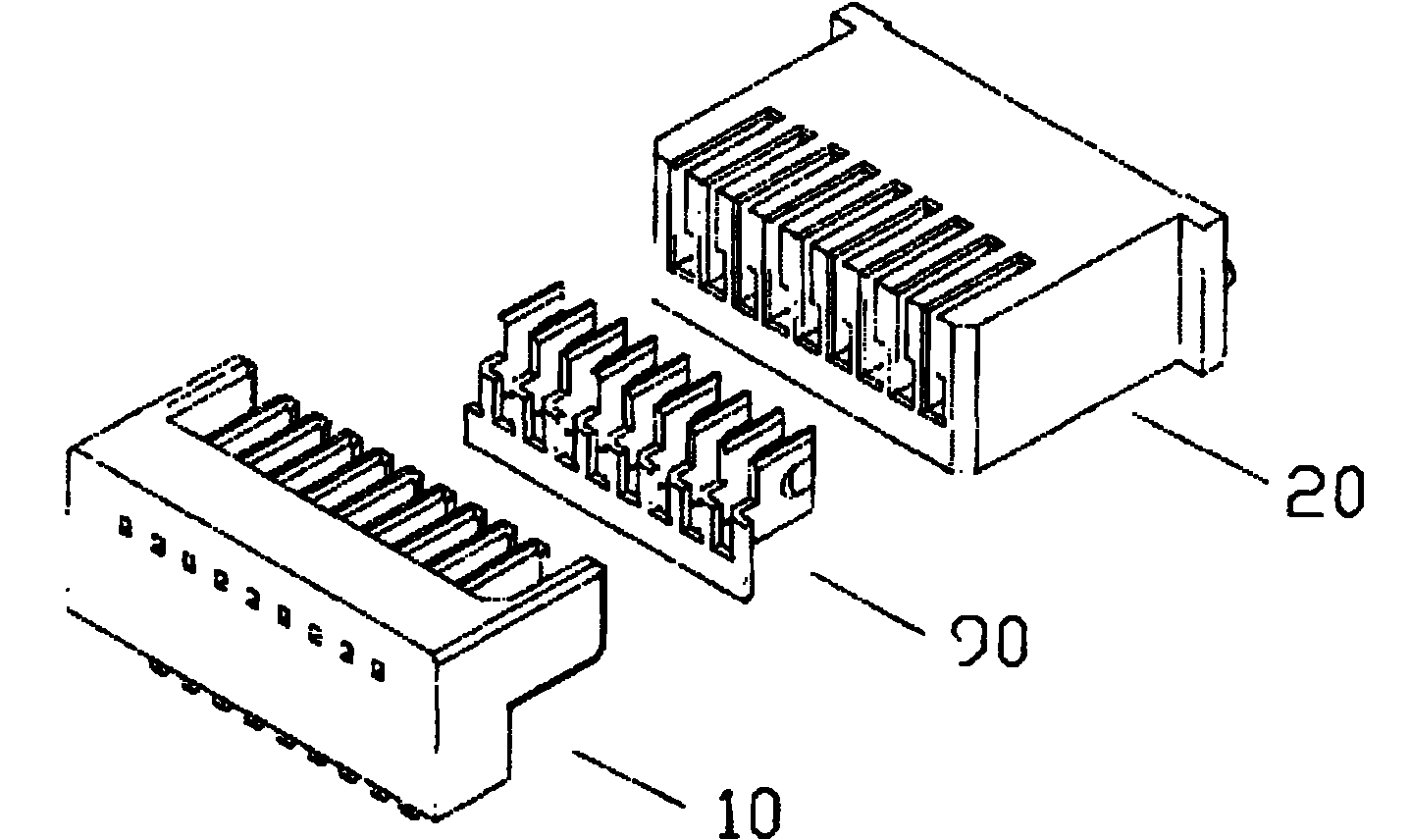

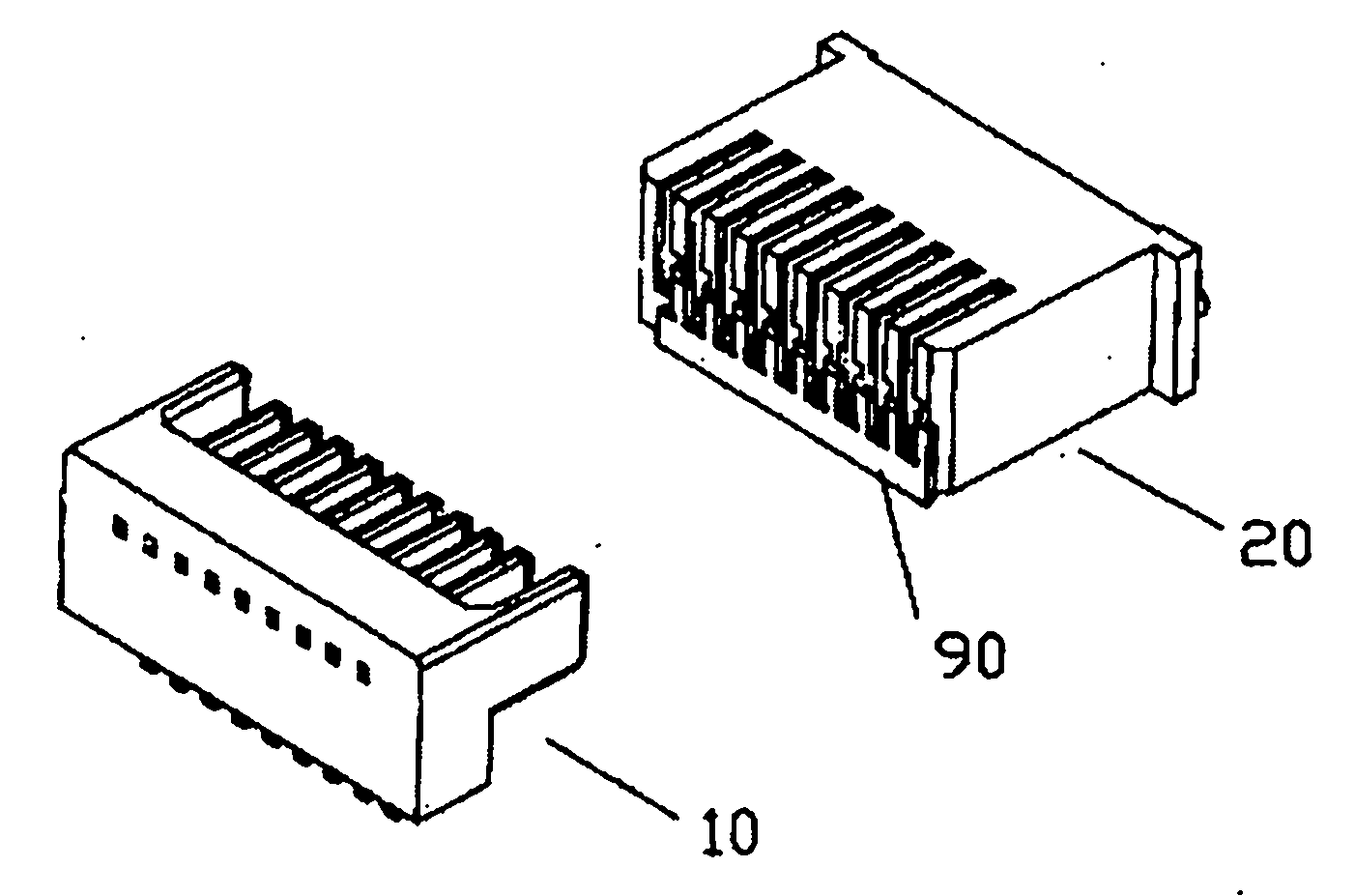

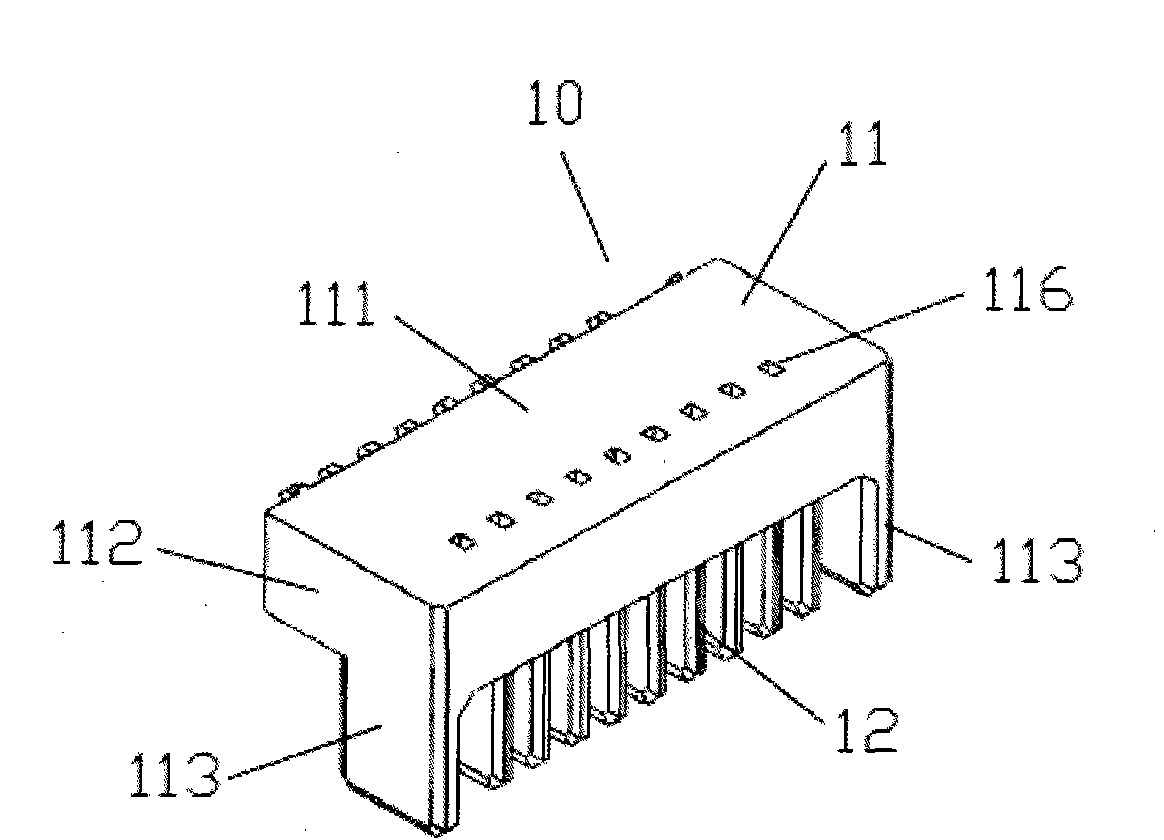

Battery connector structure

InactiveCN102315548AUnable to useEasy to useSecuring/insulating coupling contact membersTwo-part coupling devicesPack materialElectronic equipment

The invention provides a battery connector structure, in particular the battery connector structure used in portable electronic equipment and having an insulating barrier. When the electronic equipment and a power supply battery of the electronic equipment are in a matched using state, a temporary insulating state is formed between a plug connector and a socket connector of the battery connector of the electronic equipment through the installation of the insulating barrier body before use. The battery connector structure has the effects of saving package materials, space and assembling steps in use.

Owner:BELLWETHER ELECTRONIC CORP +1

Novel efficient vehicle generator

PendingCN112234745ASpeed up heat dissipationUnable to dischargeCooling/ventillation arrangementSupports/enclosures/casingsCold airElectric machinery

The invention discloses a novel efficient vehicle generator. When a rotor rotates to work, an internal fan is driven to rotate, cold air in a refrigeration box is conveyed into a shell through a cooling air duct, air cooling is performed on the motor, and meanwhile, a heat conduction grid conducts heat on the shell. A circulating water pump drives a water conveying pipe and a water outlet pipe toconvey water cooled in the refrigeration box into a water guide groove of the heat conduction grid, the heat conduction grid is cooled, and therefore a heat dissipation speed of the motor is increased, and a situation that heat generated when the motor works cannot be discharged is avoided.

Owner:江苏欣弘实业有限公司

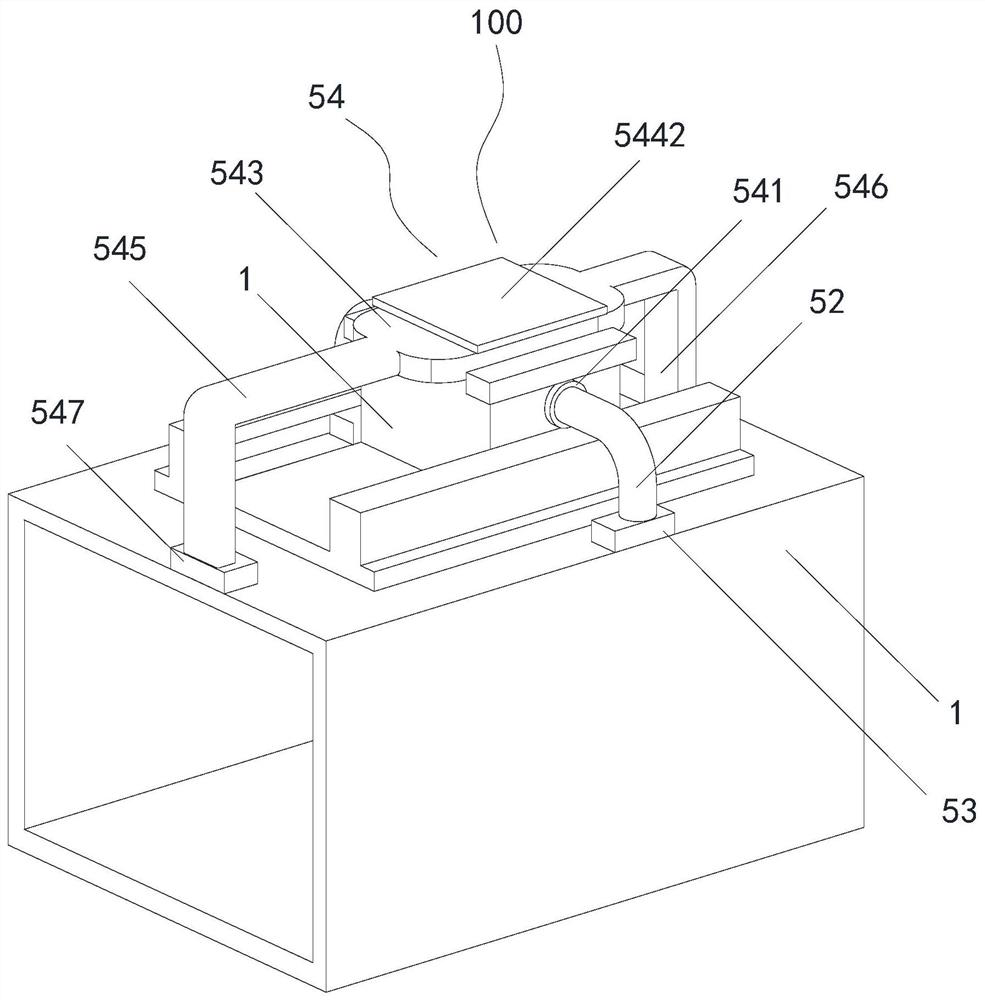

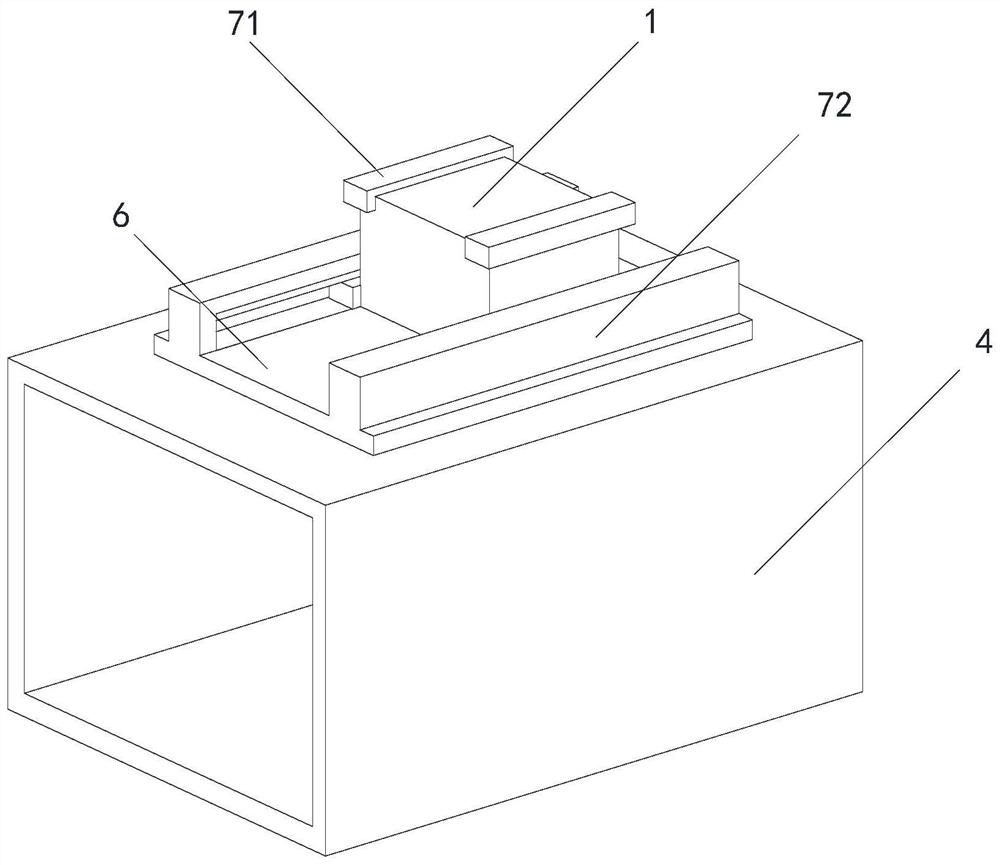

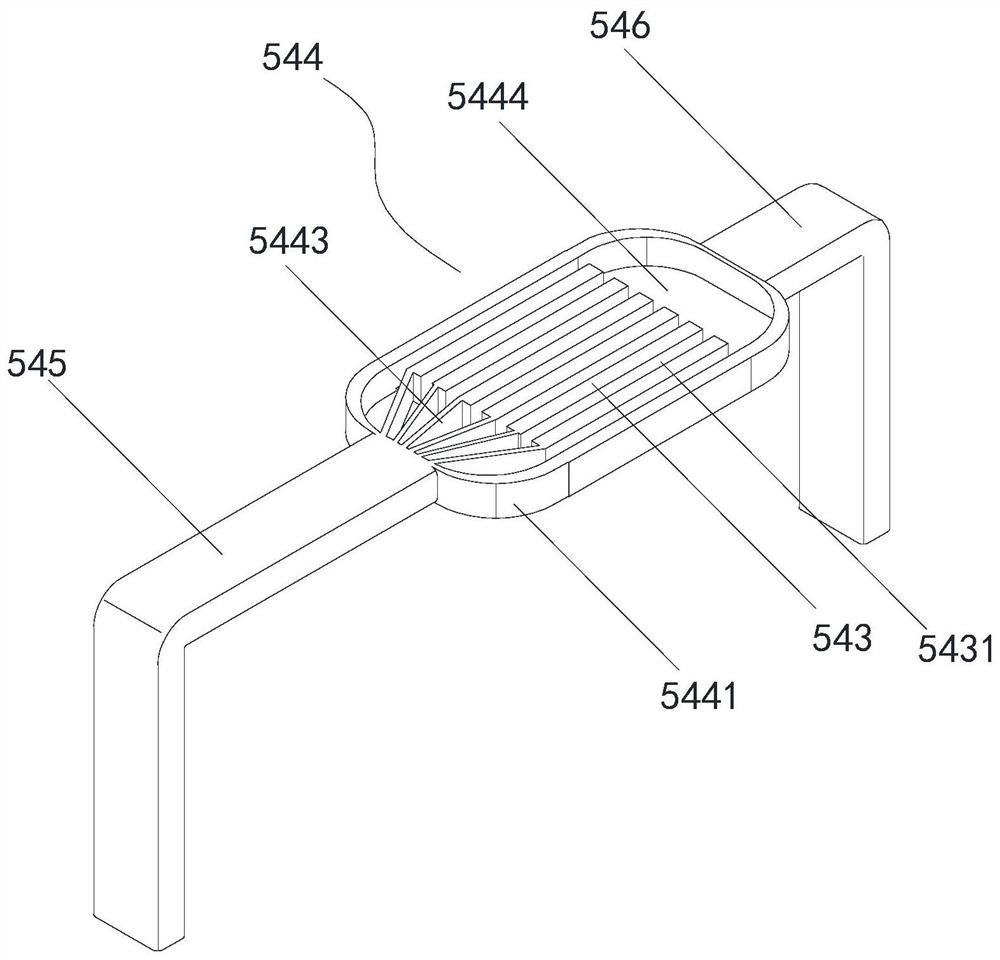

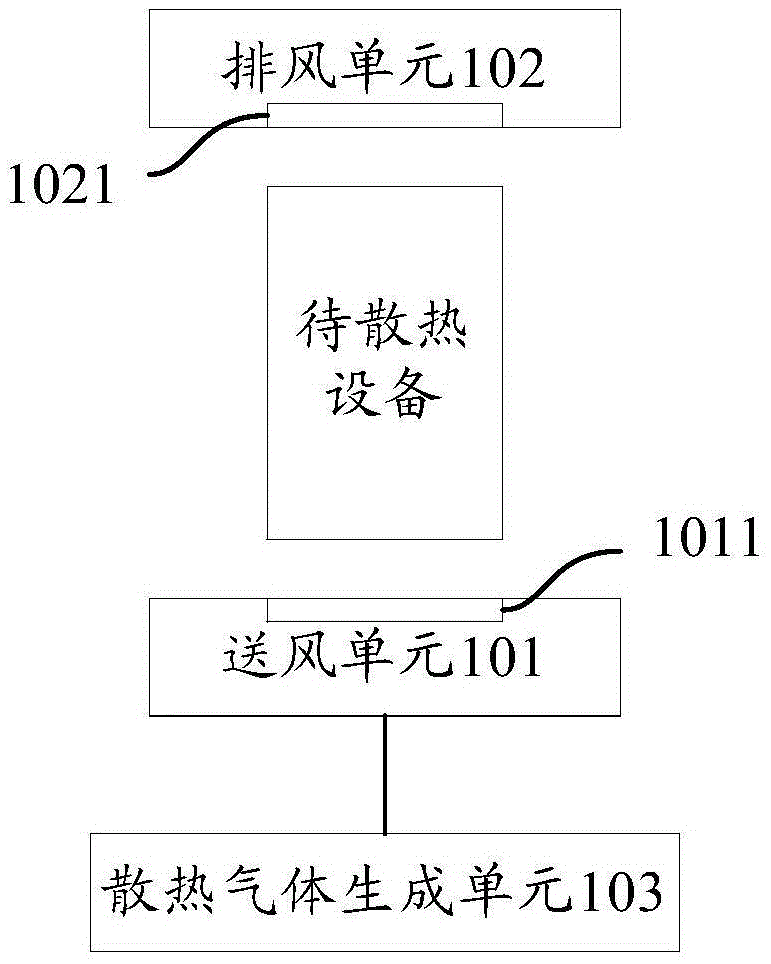

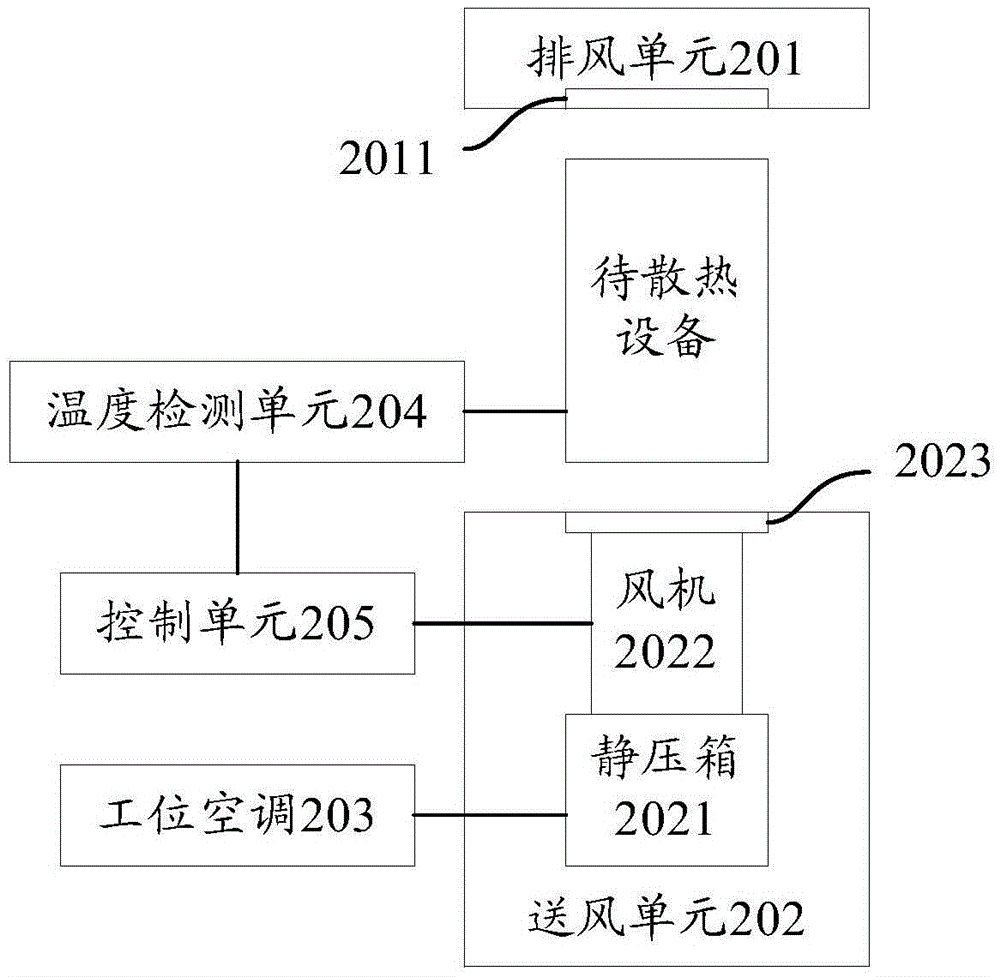

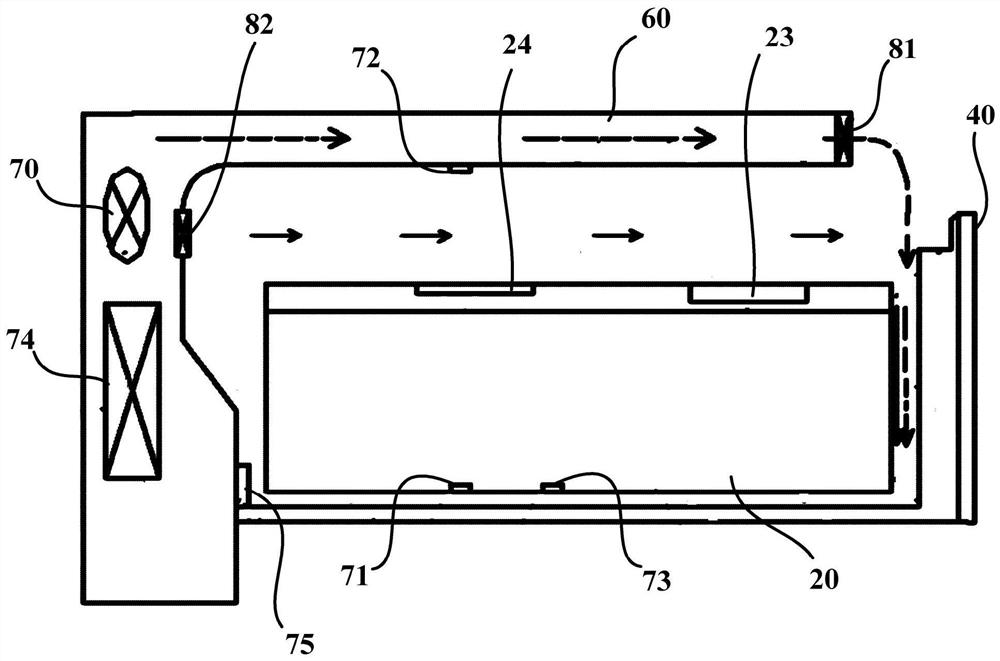

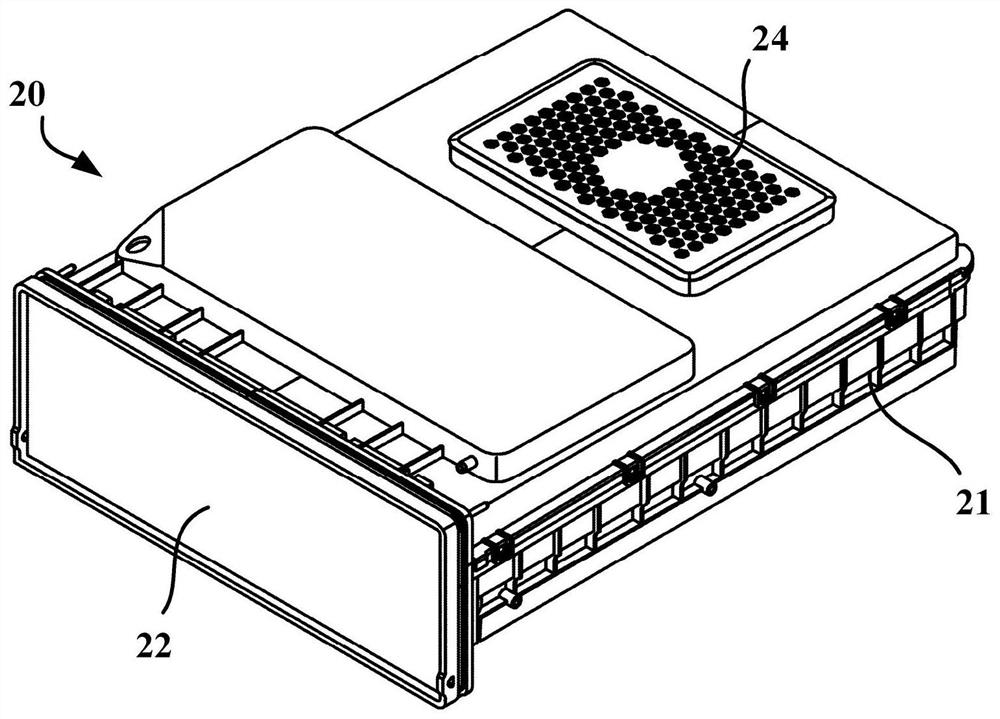

Cooling system for machine room

InactiveCN105658042AUnable to dischargeSmooth circulationCooling/ventilation/heating modificationsEngineeringCooling efficiency

The invention provides a cooling system for a machine room. The cooling system comprises an air supply unit, an air exhaust unit and a cooling gas generation unit, wherein the air supply unit comprises an air supply port; the air exhaust unit comprises an air exhaust port; the air supply port of the air supply unit is located below to-be-cooled equipment in the machine room; the air exhaust port of the air exhaust unit is located above the to-be-cooled equipment; the cooling gas generation unit is used for outputting cooling gas and guiding the output cooling gas into the air supply unit; the air supply unit is used for receiving the cooling gas input by the cooling gas generation unit and outputting the cooling gas to the machine room through the air supply port; the air exhaust unit is used for exhausting the air in the machine room through the air exhaust port. The provided cooling system for the machine room can improve the cooling efficiency.

Owner:LANGCHAO ELECTRONIC INFORMATION IND CO LTD

Graphene raw material processing technology

InactiveCN113797831AShorten mixing timeImprove mixing effect and stirring efficiencyGrapheneMixer accessoriesMachining processManufacturing engineering

The invention discloses a graphene raw material processing technology, and mixing equipment comprises a tank body and a tank cover arranged on the upper portion of the tank body, wherein the right side of the upper portion of the tank cover communicates with a feeding hopper. The invention relates to the technical field of graphene processing. According to the graphene raw material processing technology, a transmission main shaft drives a rotating disc to rotate, a first limiting hole in the rotating disc pushes a transmission rod to rotate, the transmission rod slides in an annular curve rail groove through a transmission sliding block, and the transmission rod rotates and moves up and down; and in the up-down moving process of the transmission rod, a first connecting rod pushes a material separating plate to swing up and down, and raw materials enter the tank body through the material leaking holes, so the graphene raw materials are uniformly and slowly fed; therefore, the stirring time is shortened, the mixing effect and the stirring efficiency are improved, the progress of a project is not influenced, the effect that the materials are easily and fully stirred is achieved, and the problem that materials are not fully stirred easily due to the fact that most stirring machines are simple in structure is solved.

Owner:于润发

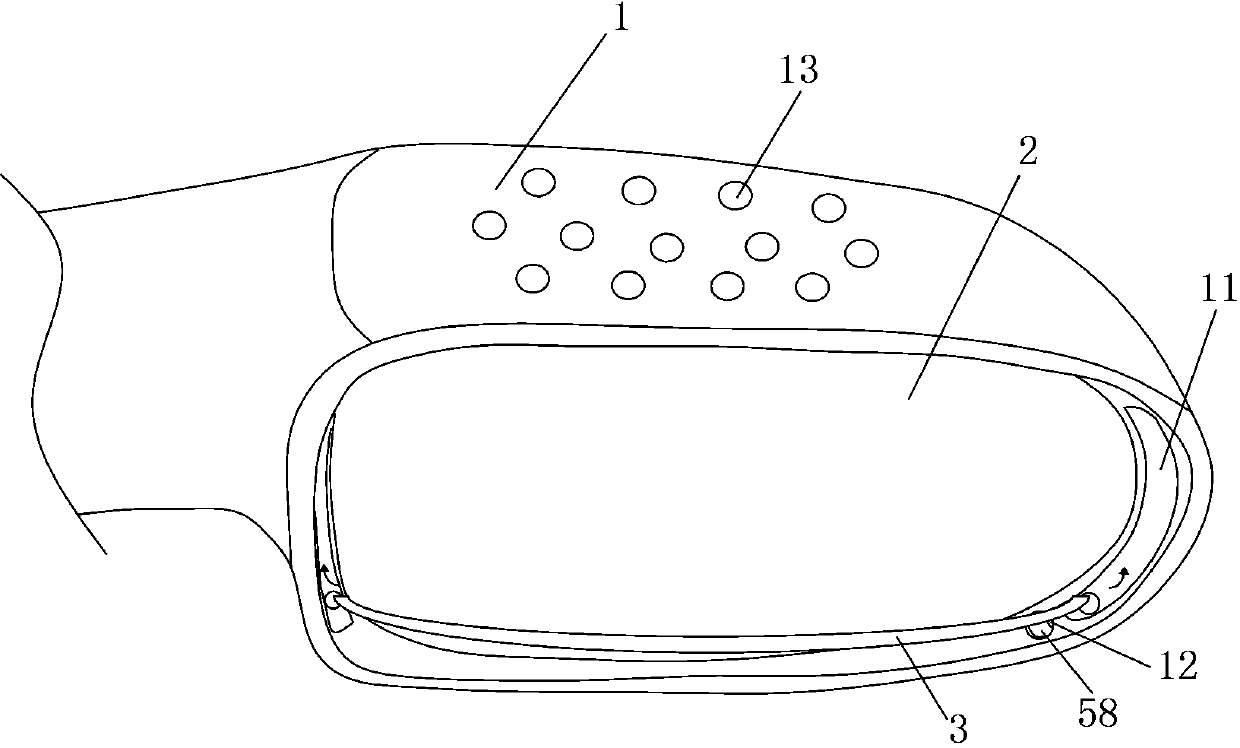

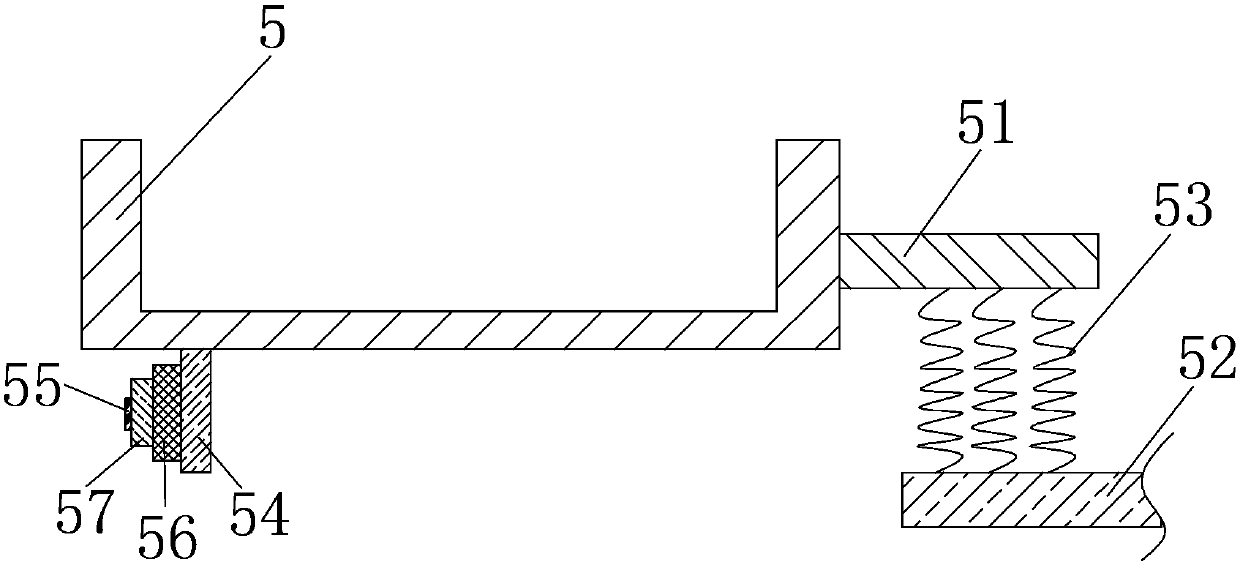

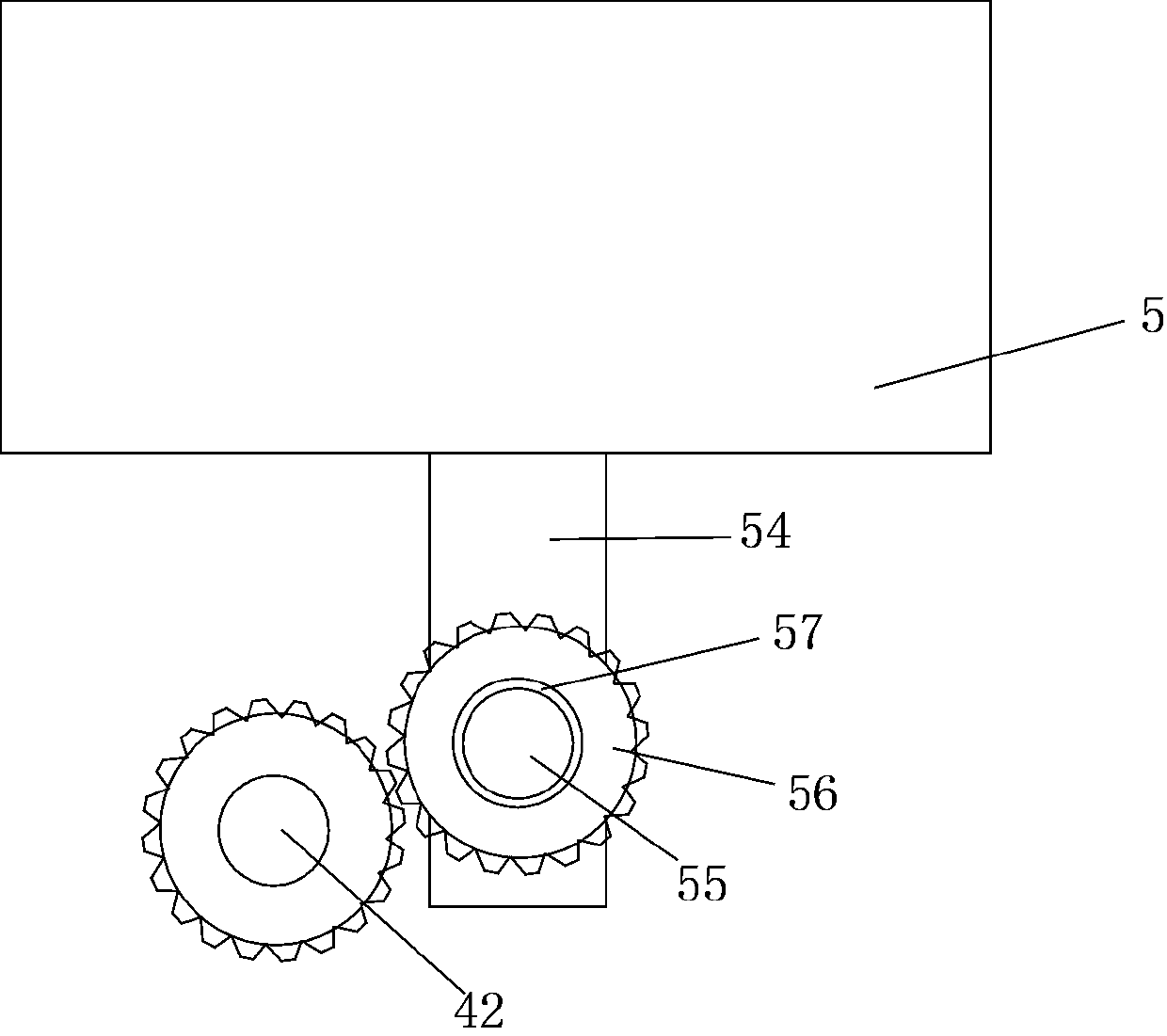

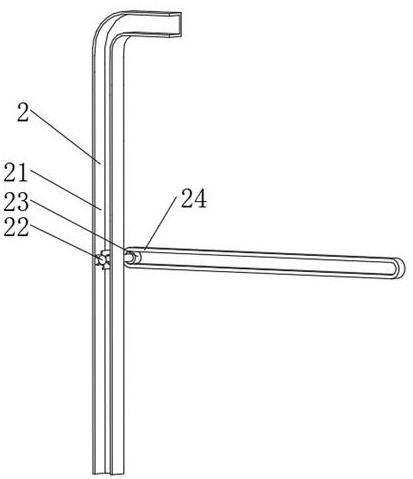

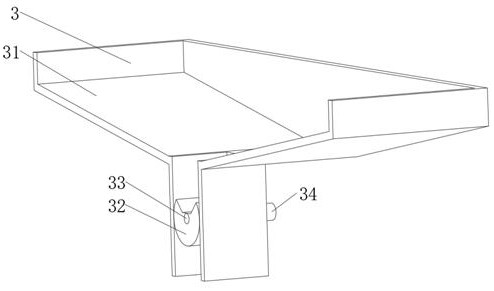

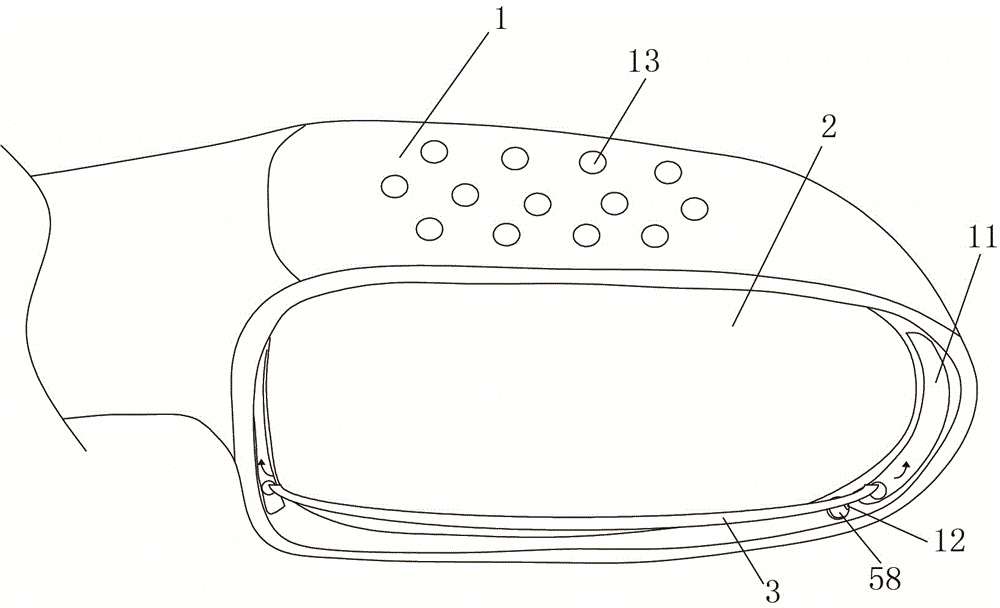

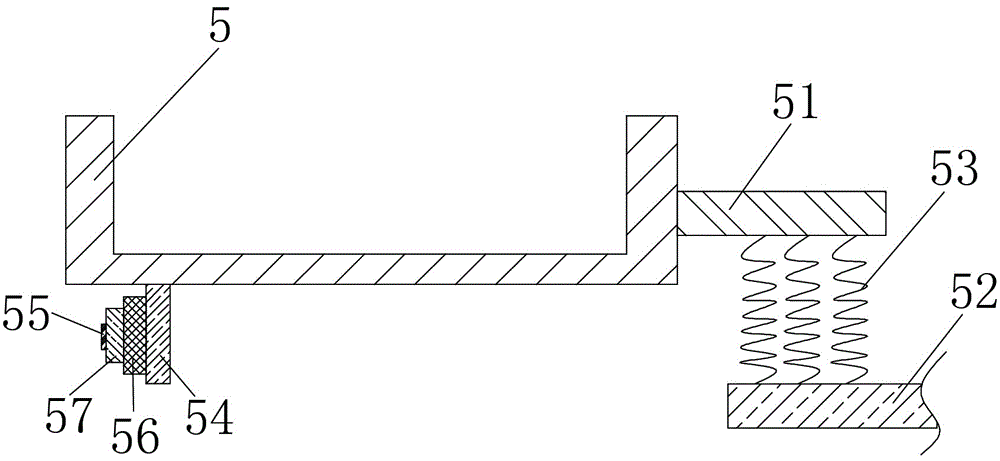

Rear view mirror

InactiveCN104129368AUnable to dischargePromote excretionVehicle cleaningOptical viewingElectric machineryEngineering

The invention relates to a rear view mirror. The rear view mirror comprises a casing, wherein rear view mirror glass is arranged on the casing, a slide groove and a first through hole are formed in the casing, the inner part of the slide groove is connected with a windscreen wiper, a sensor is arranged on the windscreen wiper, a motor is arranged in the casing and is connected with a rotating shaft, a first gear is arranged on the rotating shaft, a second through hole is formed in the side surface of the casing, a tray is arranged in the casing, a connecting piece is arranged at the side of the tray, a fixing piece is arranged below the connecting piece, the connecting piece and the fixing piece are connected through an elastic assembly, a first connecting rod is arranged on the lower side surface of the tray, a second connecting rod is arranged at the side surface of the first connecting rod, the second connecting rod is connected with a second gear, a flange is arranged at the side surface of the second gear, and the flange is connected with a rubber strip of which the end part is connected with the windscreen wiper. For the rear view mirror disclosed by the invention, the tray is used for collecting rain, the second gear can move downwards by the change of the weight of the tray, the second gear and the first gear are matched to use, and the motor rotates to drive the windscreen wiper on the rear view mirror glass to repeatedly move up and down, so that the rain on the rear view mirror glass is cleaned.

Owner:YUYAO ELEVATOR AUTO PARTS

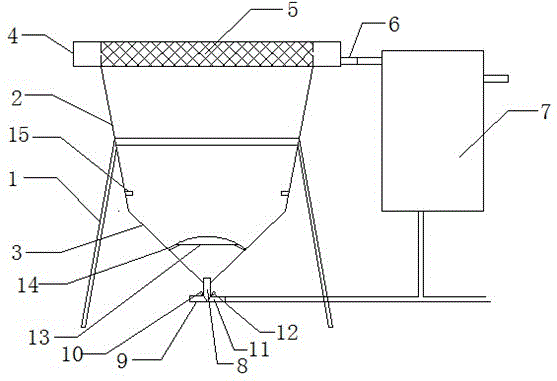

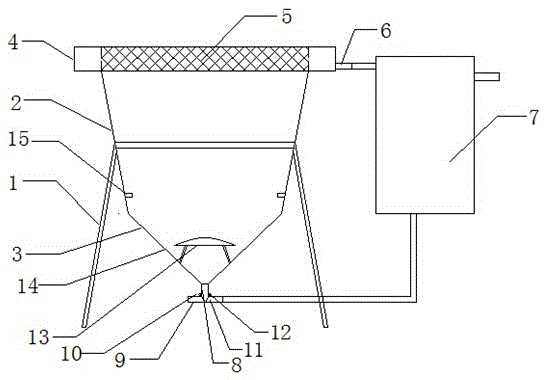

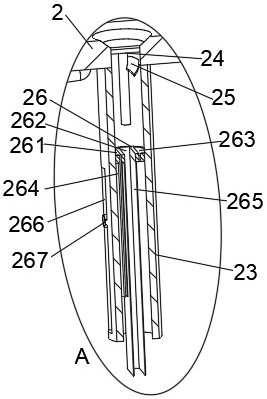

Loach fry hatching device

InactiveCN105519467AAutomatic temperature adjustmentStable temperatureClimate change adaptationPisciculture and aquariaWater flowInlet valve

The invention discloses a loach fry hatching device. The loach fry hatching device comprises a mounting rack, an upper barrel body and a lower barrel body, wherein both the upper barrel body and the lower barrel body are inverted conical structures, the upper barrel body is movably arranged on the mounting rack, an overflow groove is formed in the upper end of the upper barrel body, a screen mesh is arranged in the overflow groove and can completely cover an upper barrel body opening, a water outlet pipe is arranged at one end of the overflow groove and is connected with a water purifying device, a communicating pipe is arranged at the bottom of the lower barrel body and communicates with the lower barrel body, the lower end of the communicating pipe communicates with a fry outlet pipe and a water inlet pipe separately, the other end of the water inlet pipe communicates with the water purifying device, a fry outlet valve is arranged at the joint of the fry outlet pipe and the communicating pipe, a water inlet valve is arranged at the joint of the water inlet pipe and the communicating pipe, a concave circular baffle is arranged above the communicating pipe, a plurality of connecting bars are uniformly arranged around the circular baffle, and a plurality of aerators are uniformly arranged on the internal wall of the upper barrel body. According to the loach fry hatching device, through the cooperative action of the aerators and the circular baffle, the direction of water flow is changed, the amount of dissolved oxygen in barrels is increased, and the survival rate of hatching is increased.

Owner:太和县旭升水产养殖有限公司

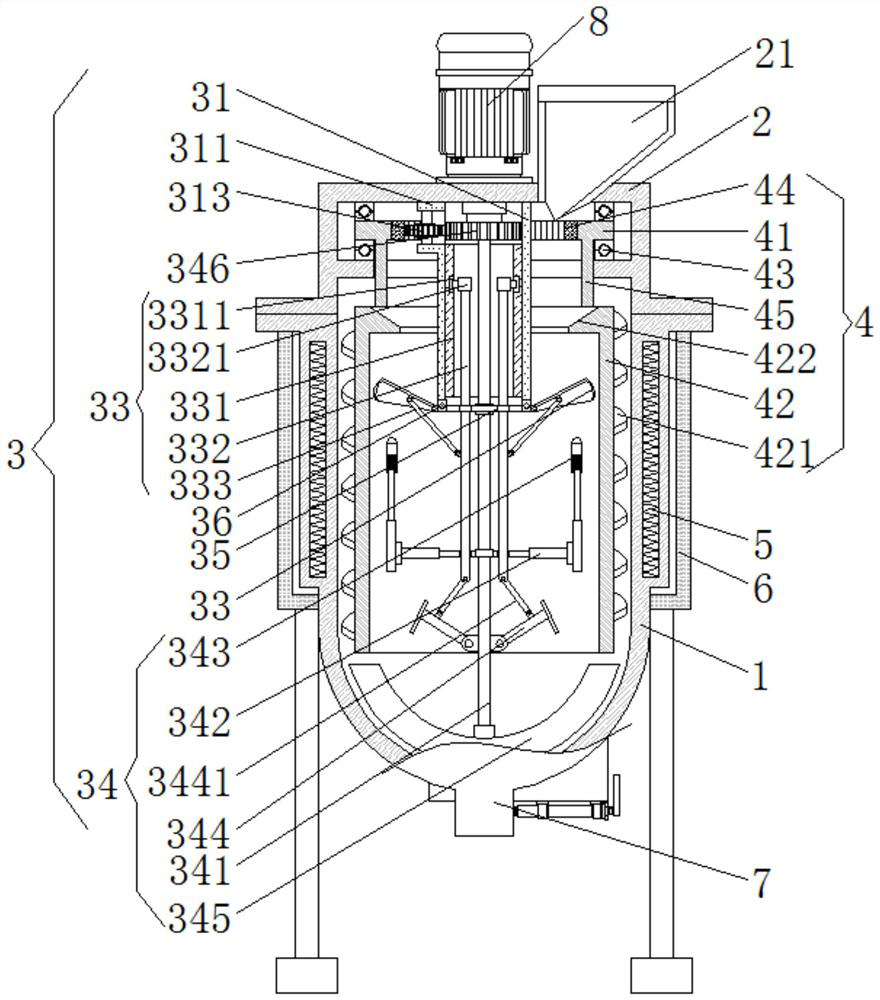

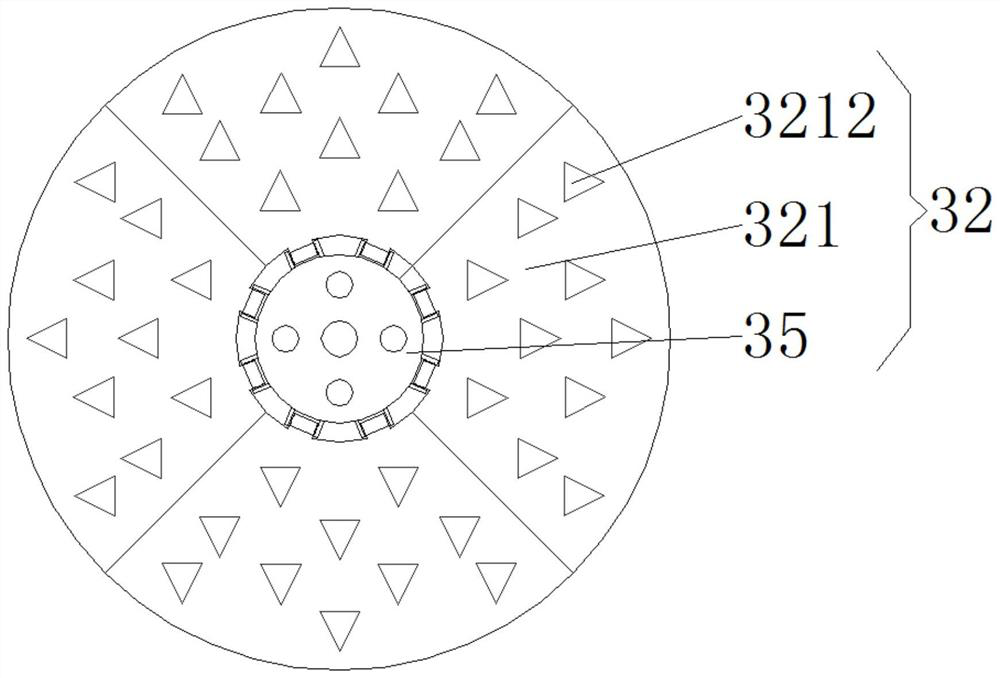

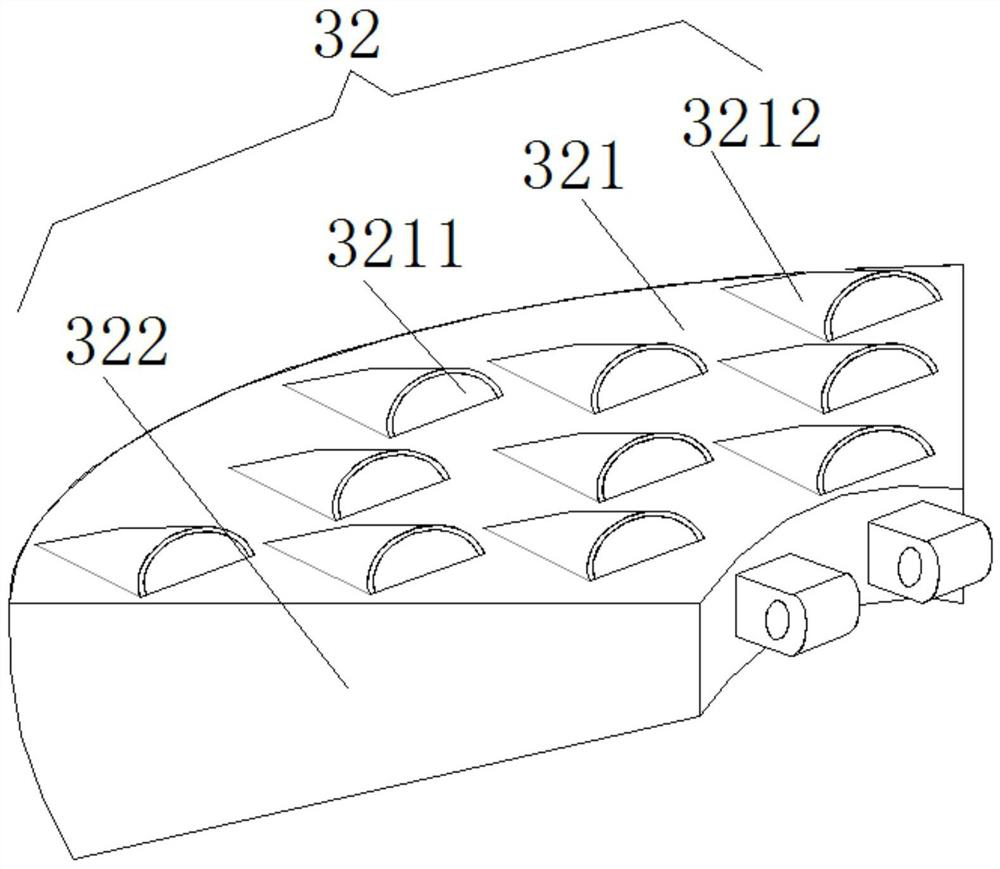

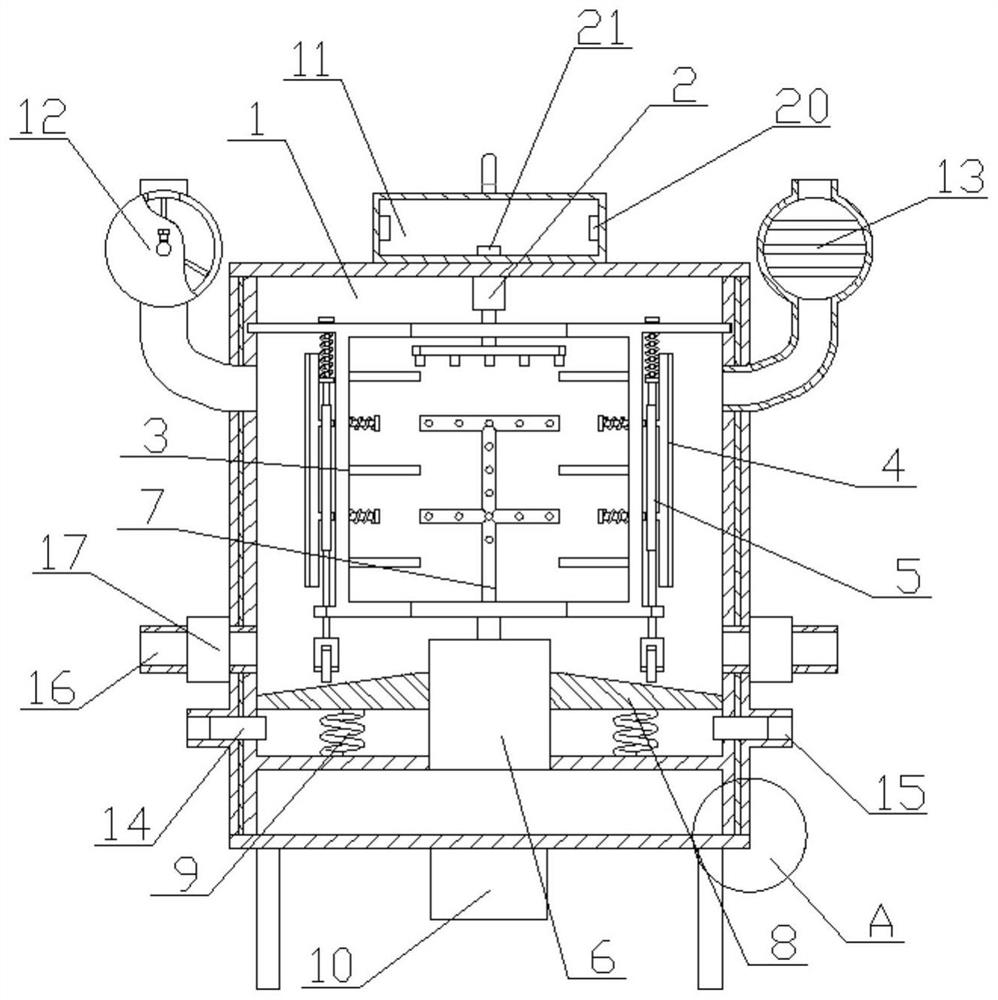

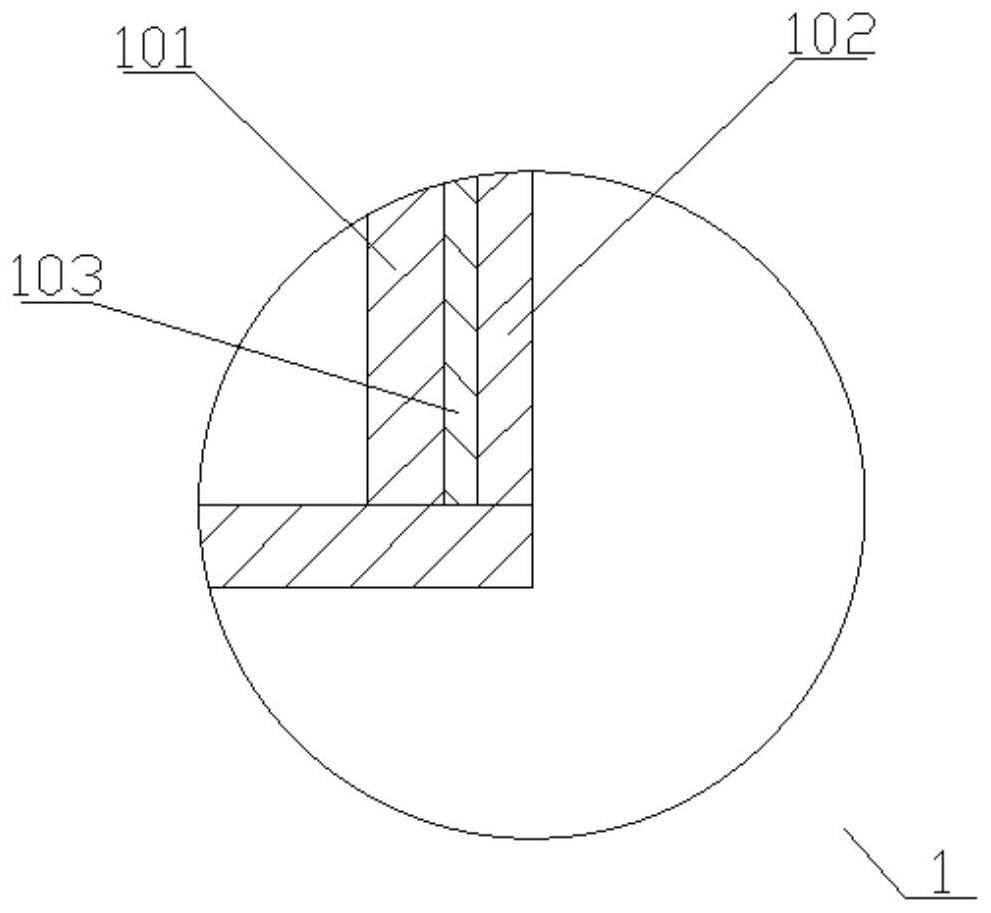

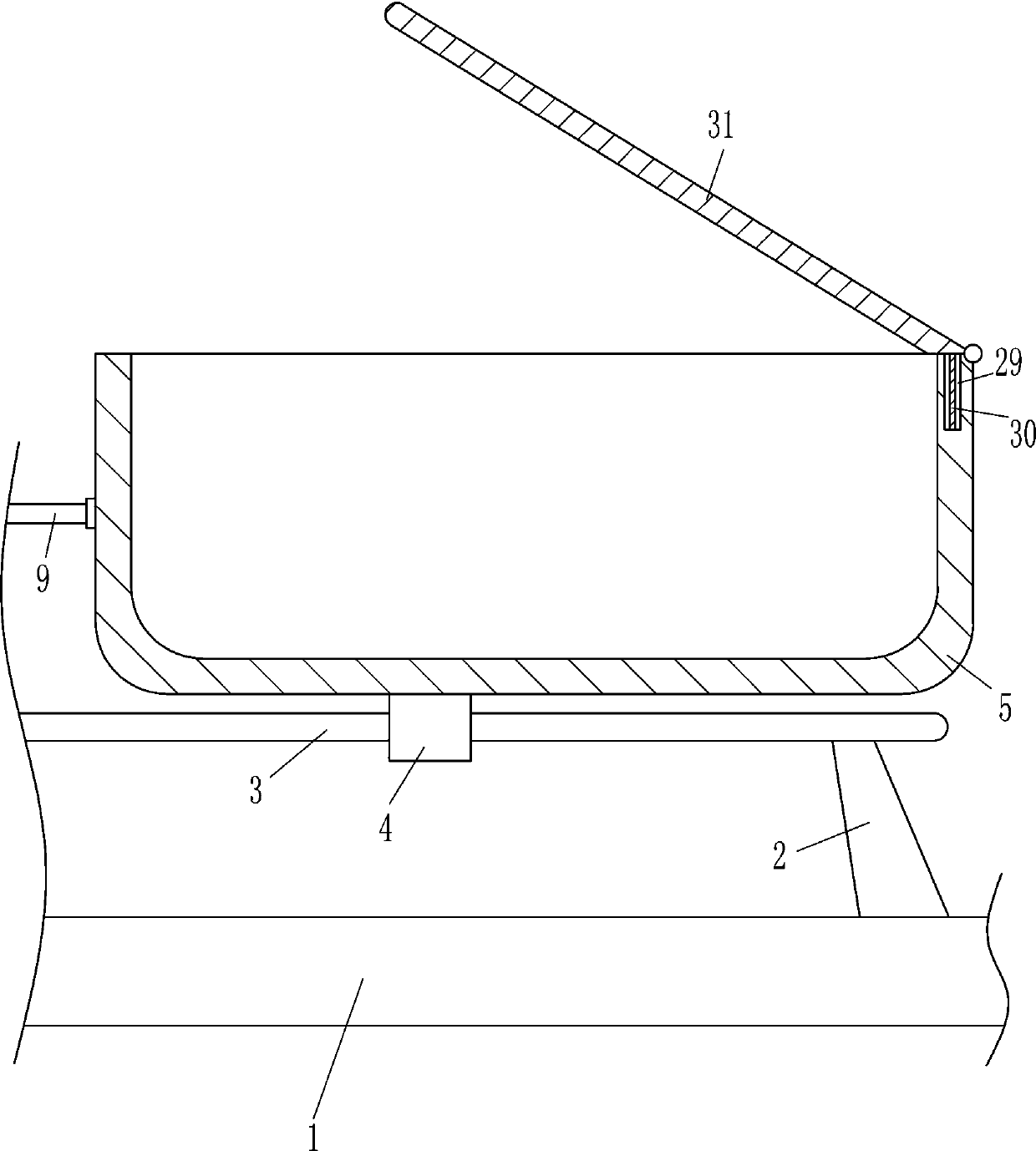

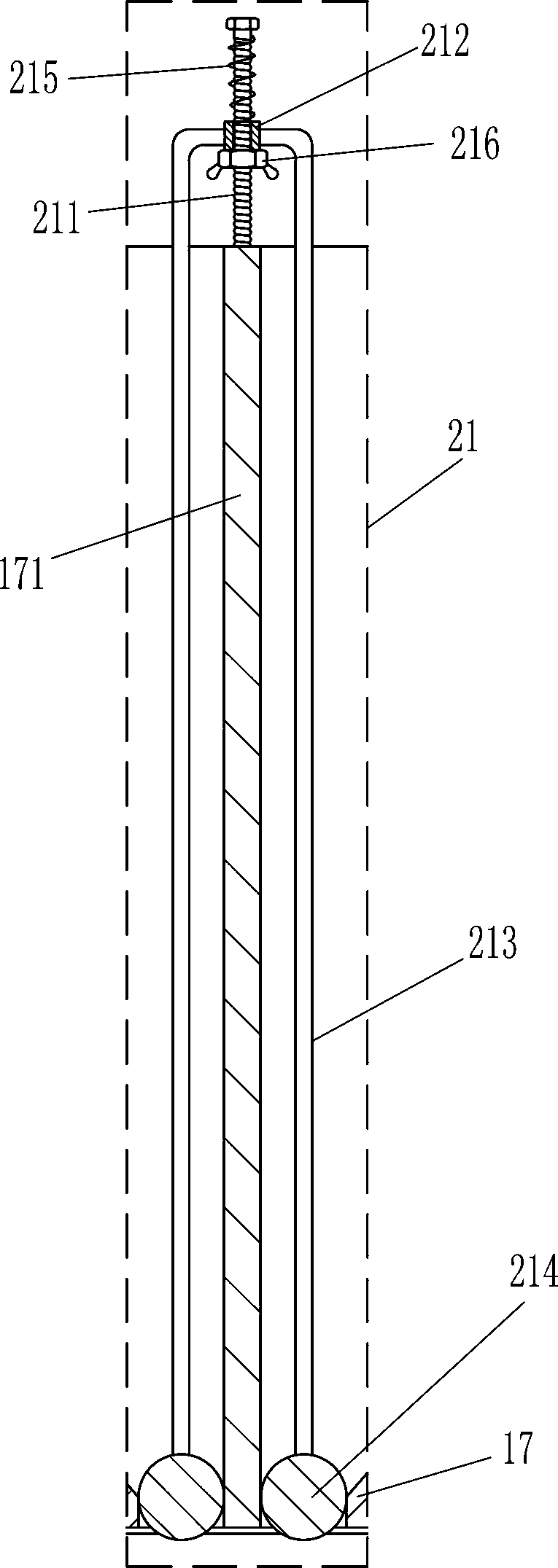

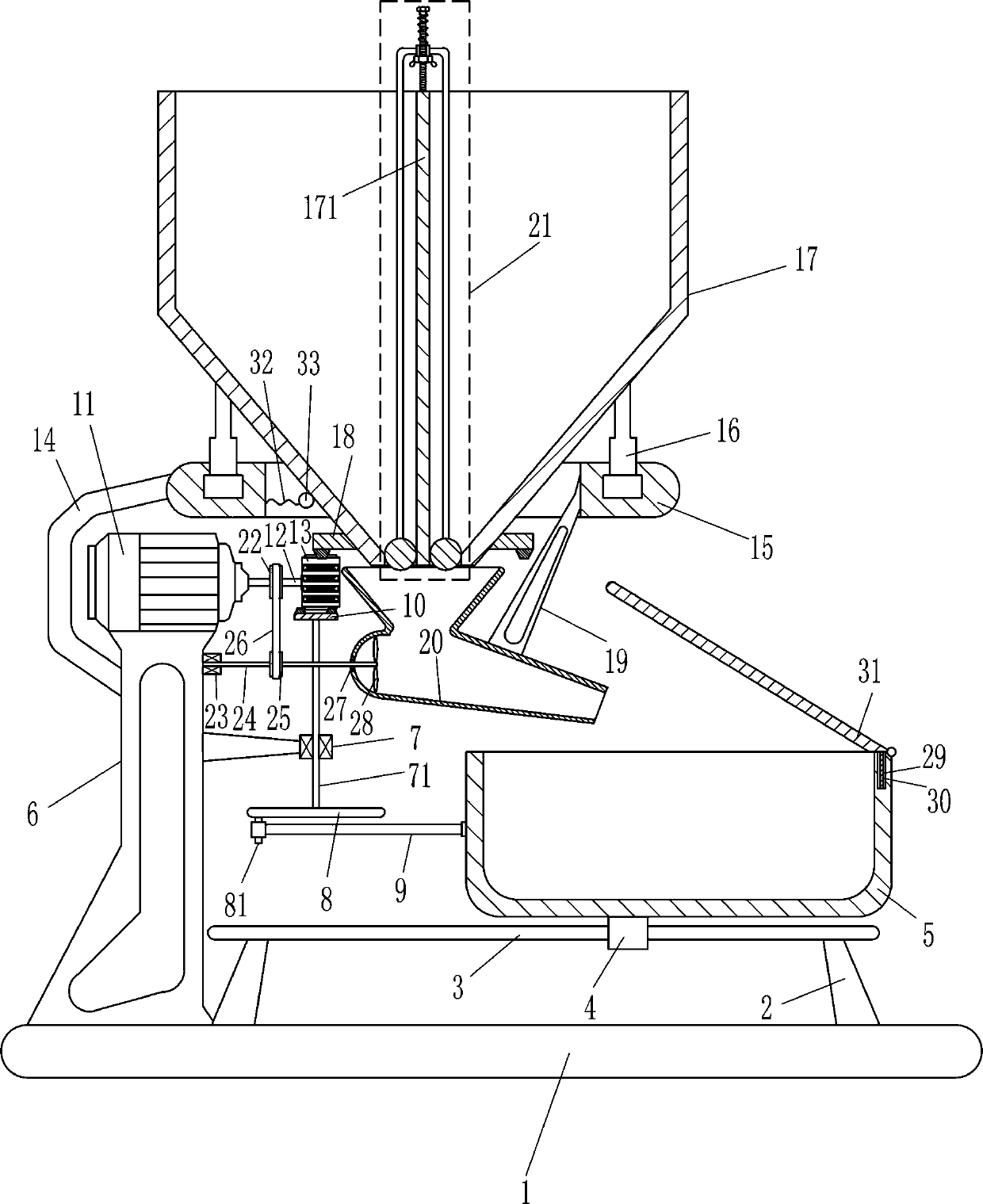

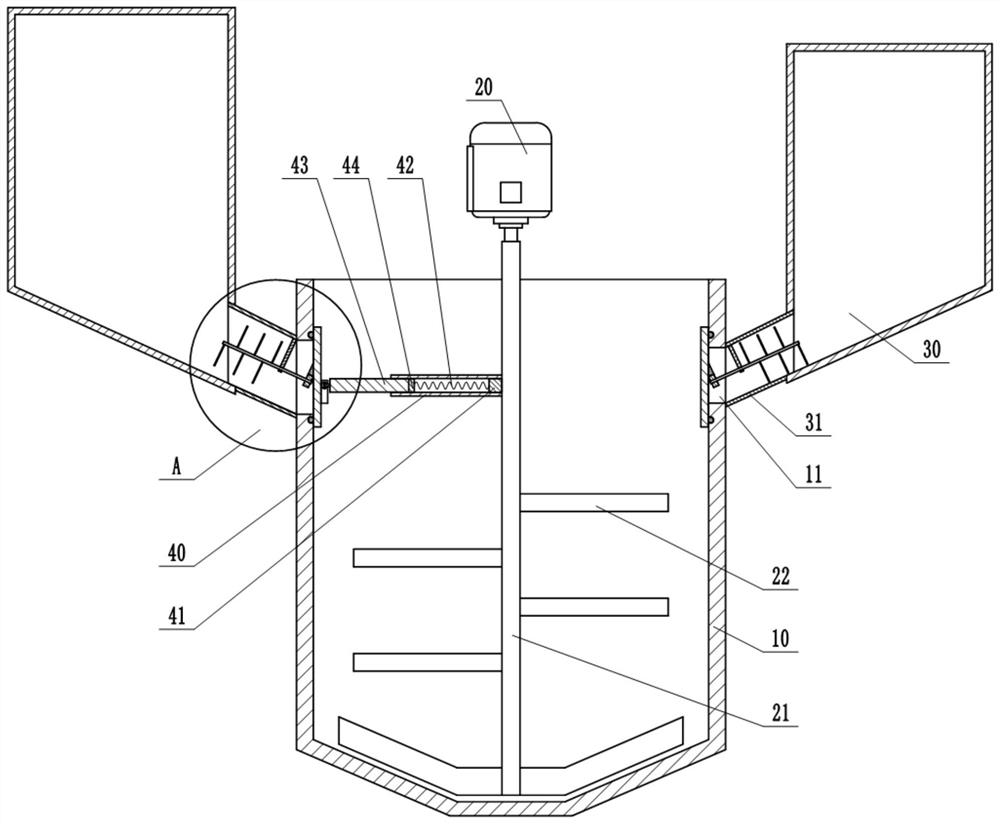

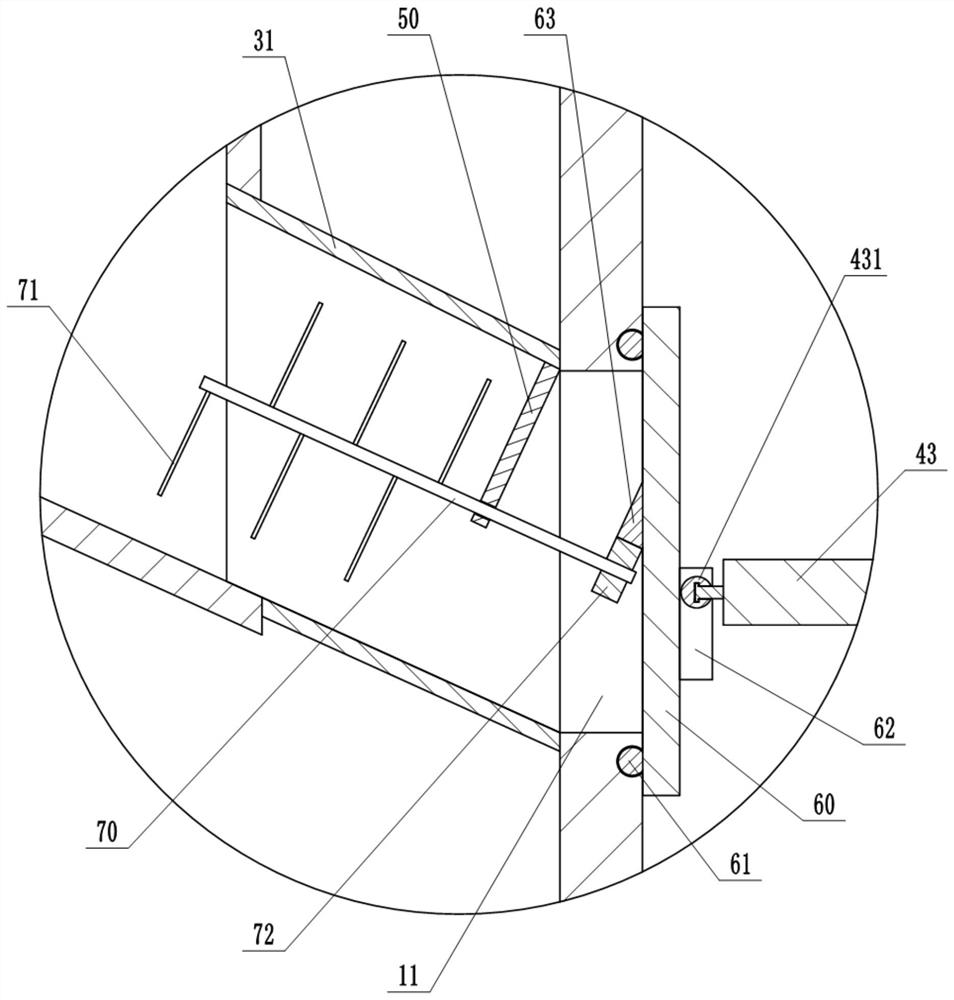

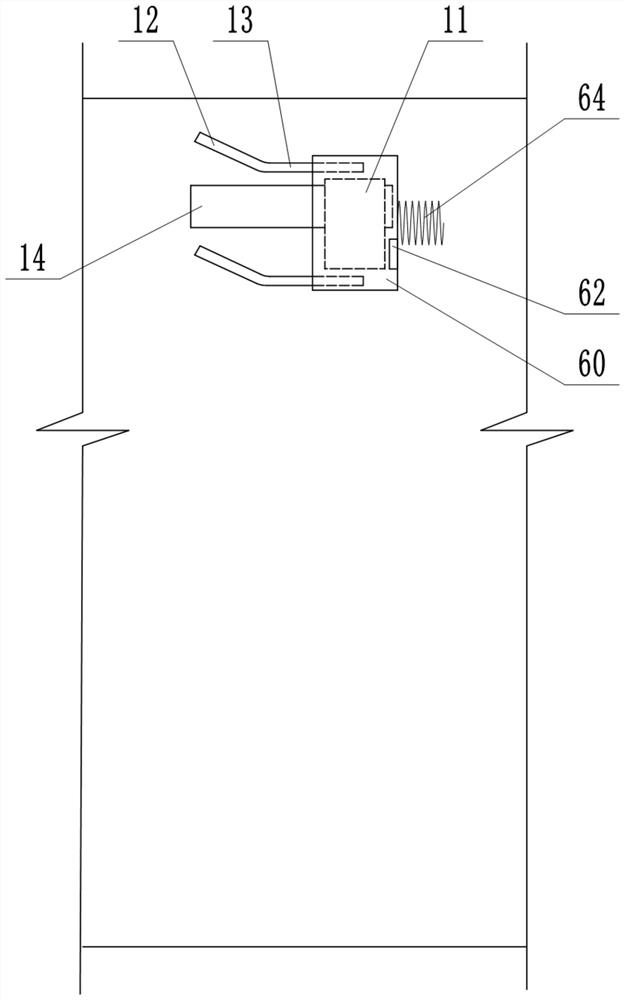

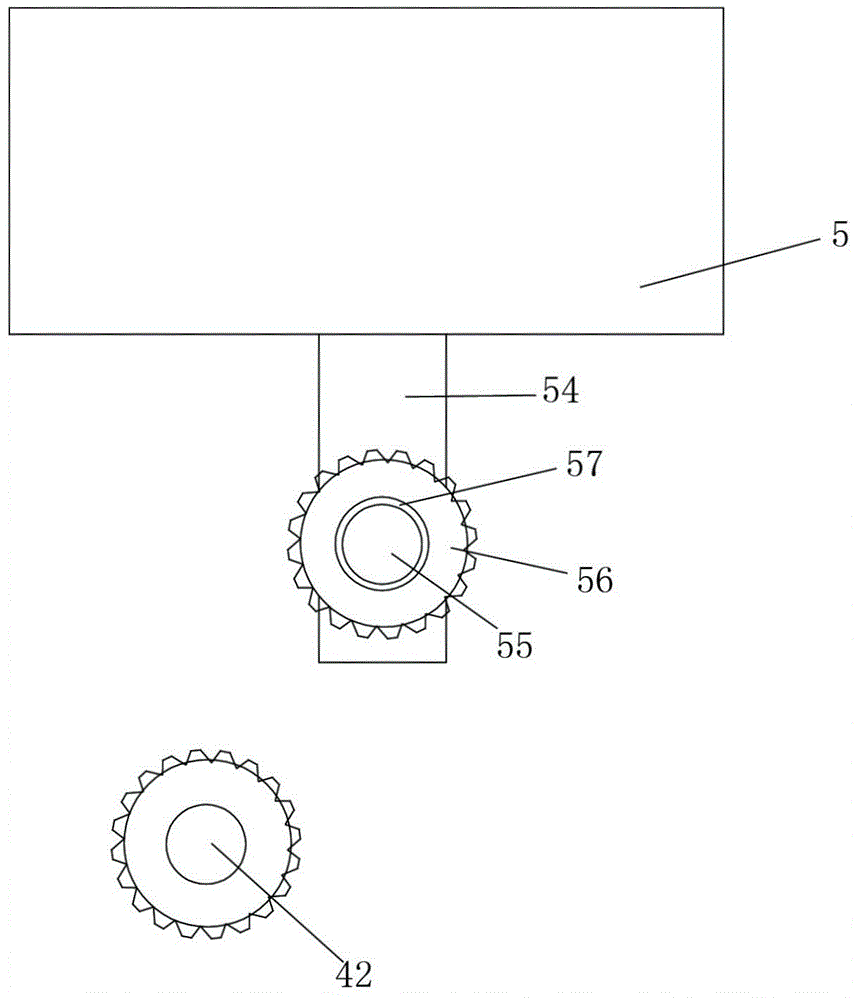

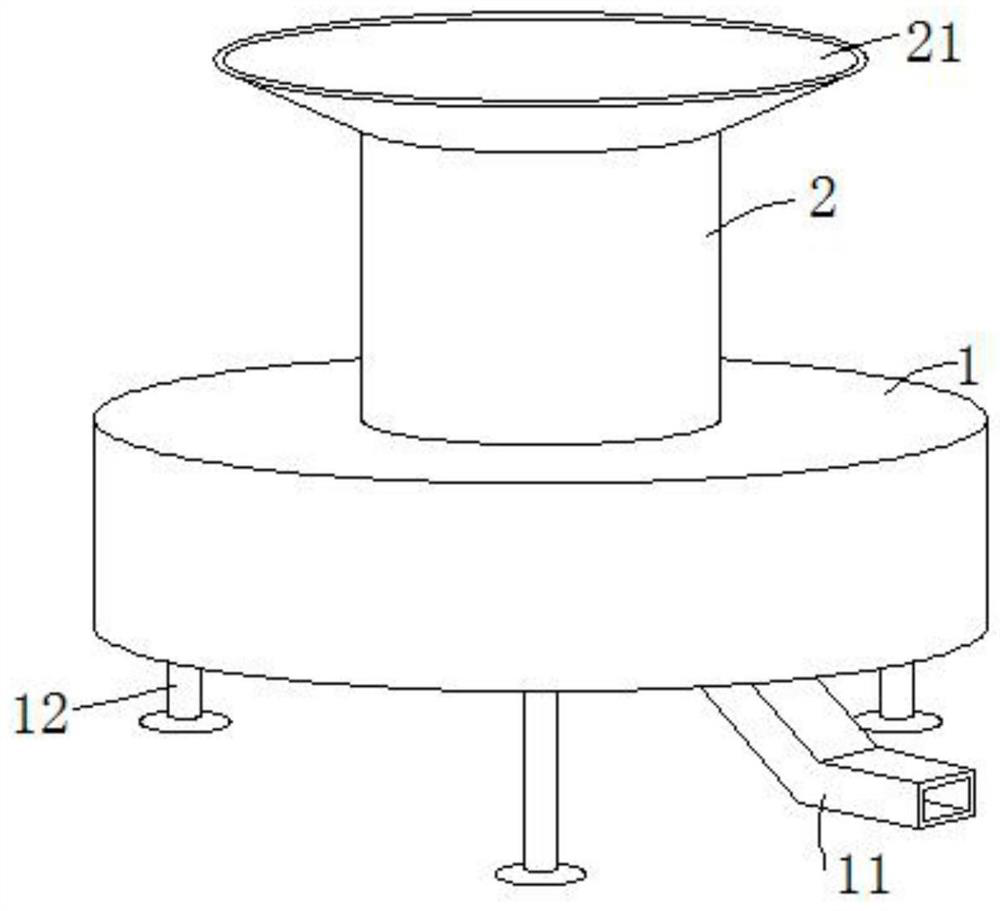

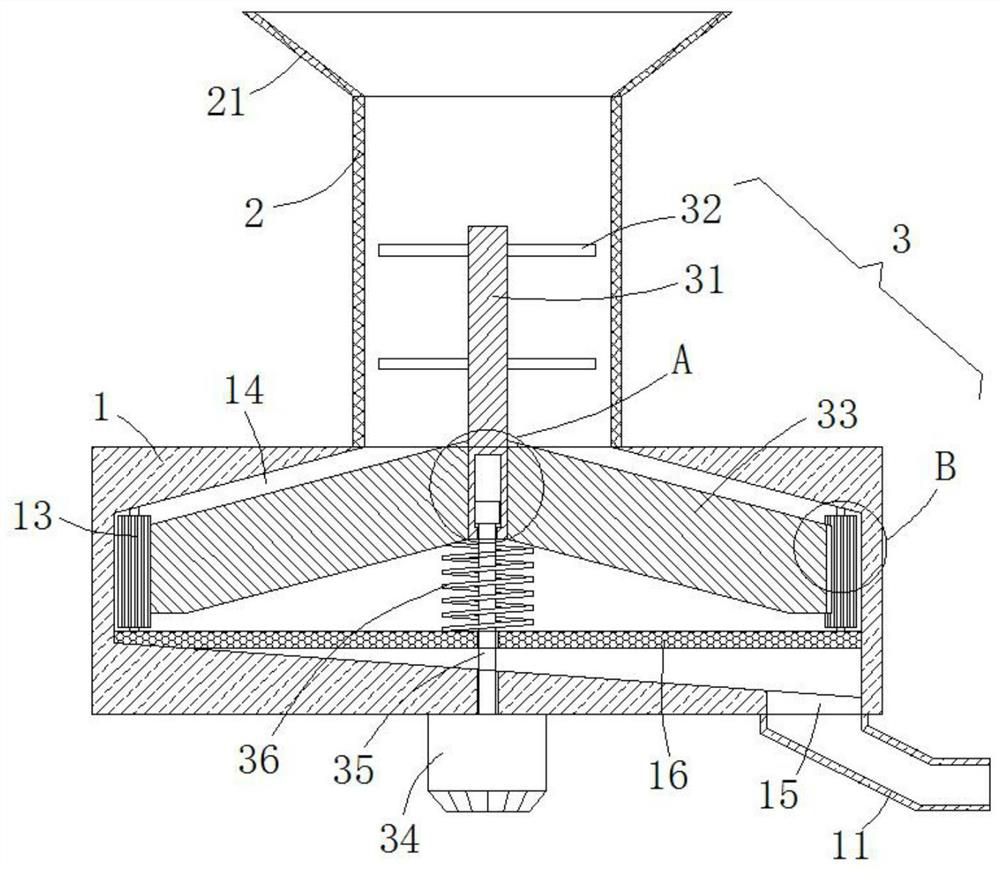

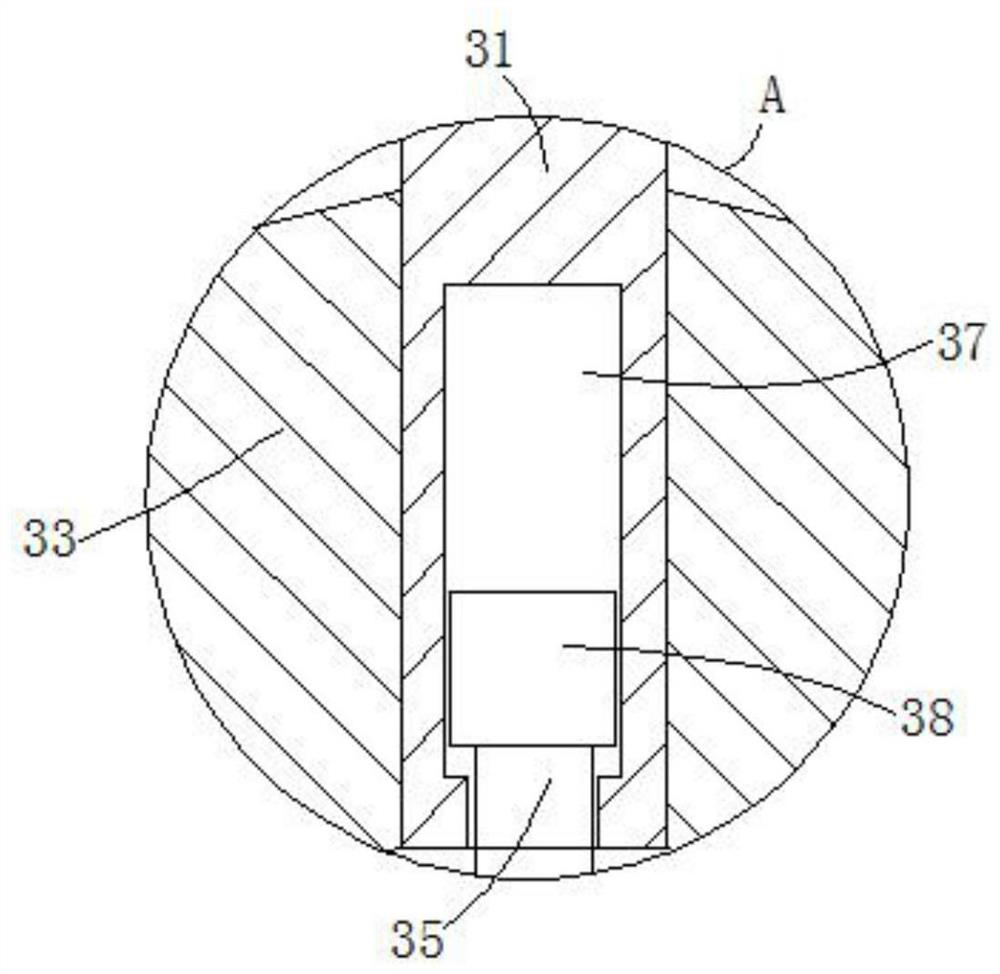

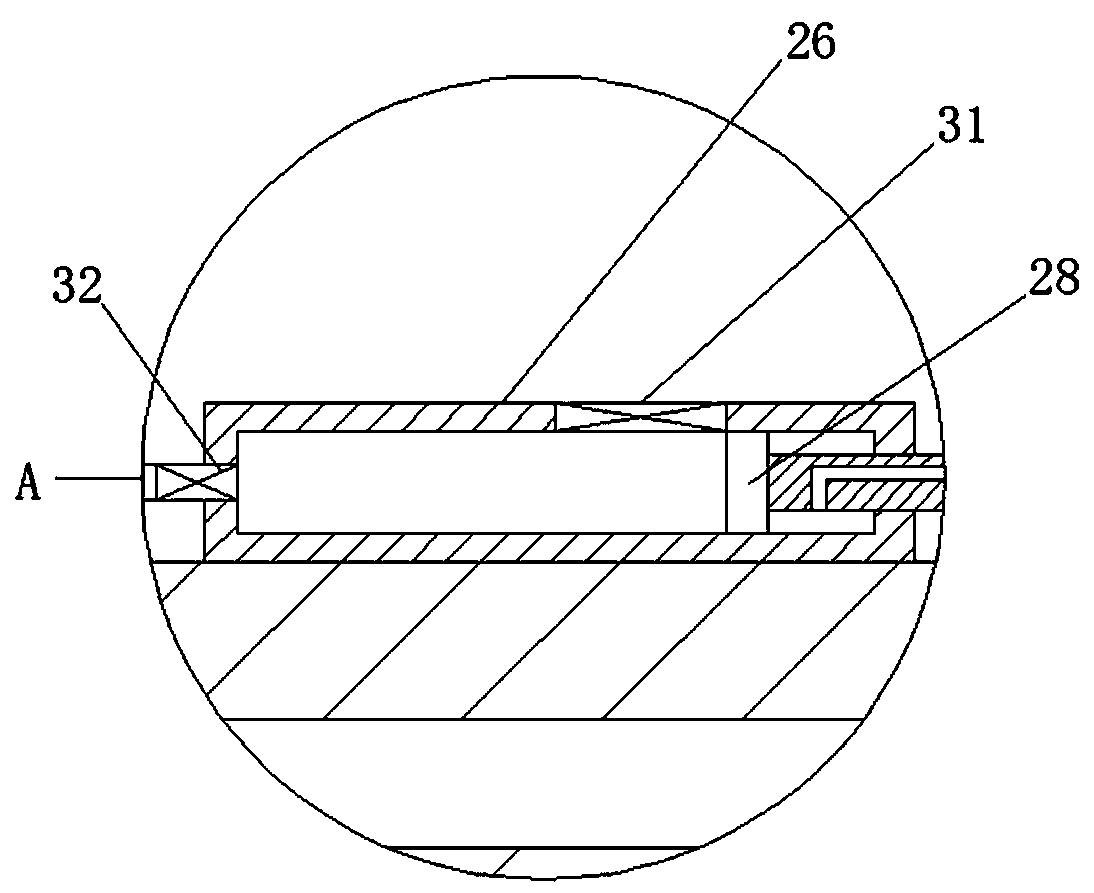

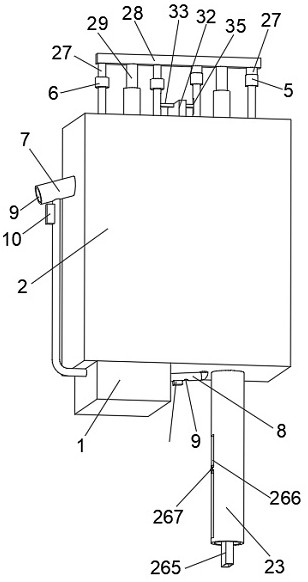

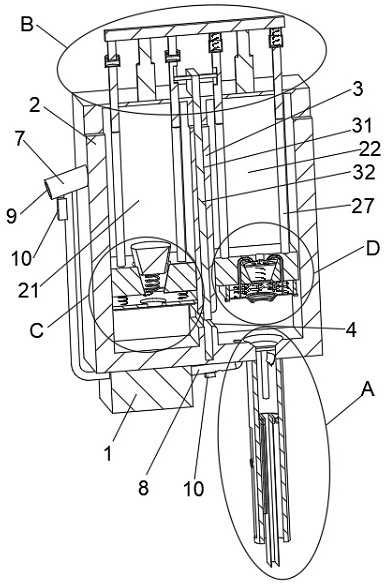

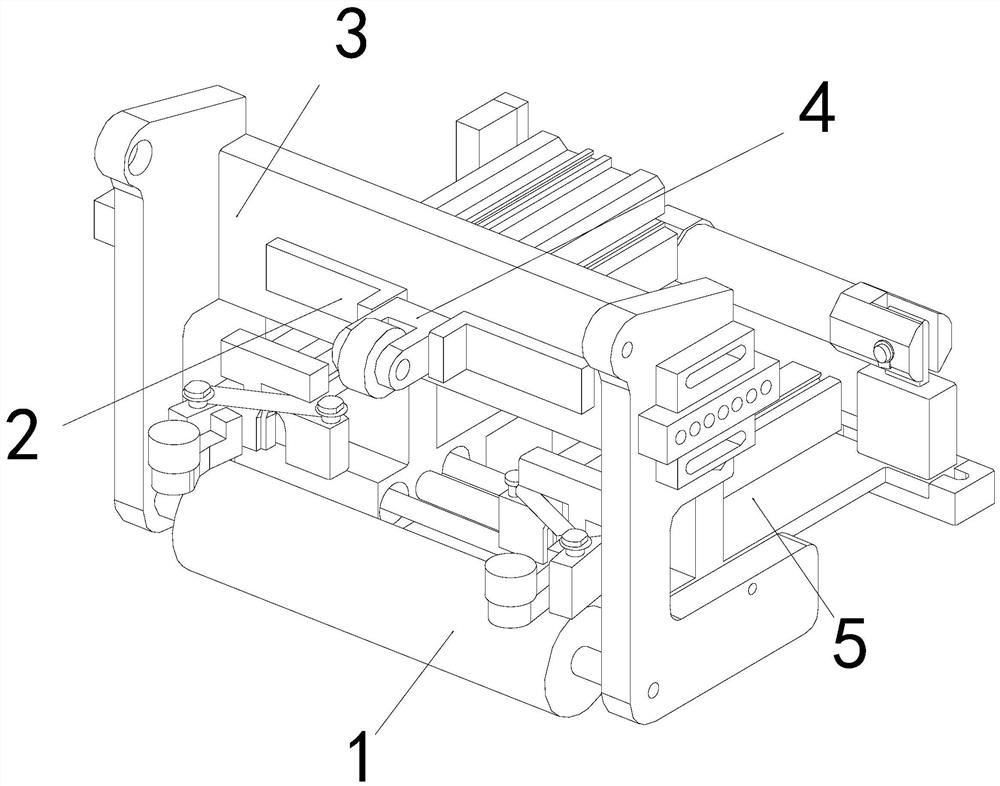

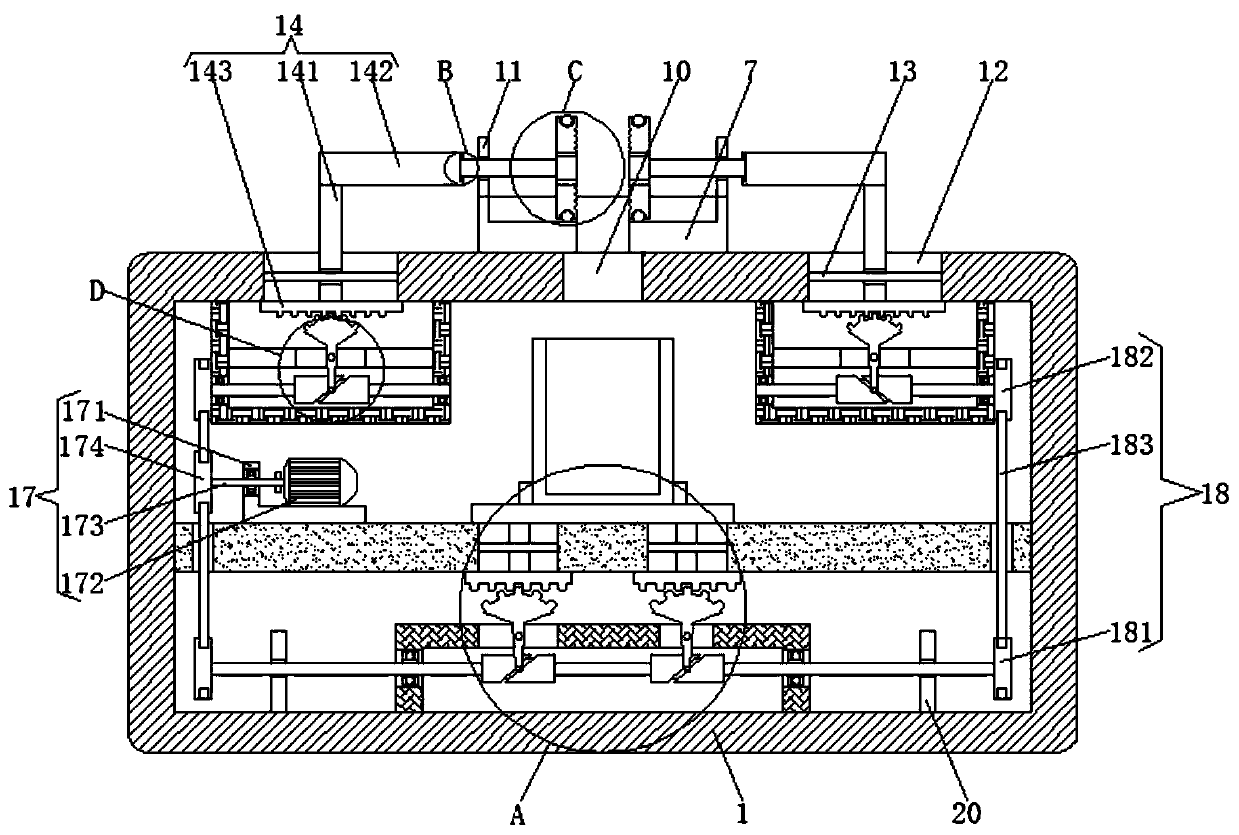

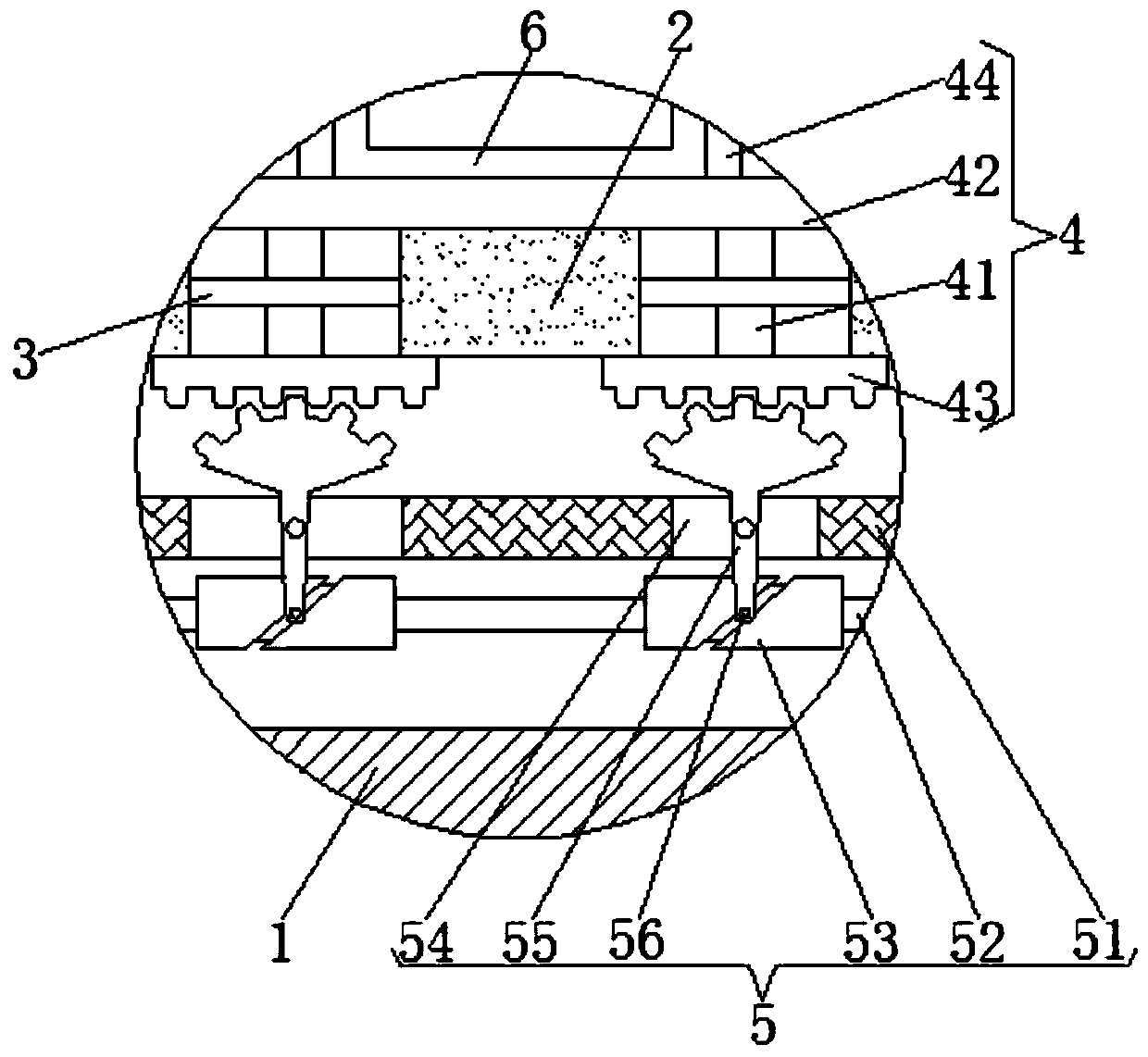

Carbonization equipment for processing silicon-carbon negative electrode material of lithium ion battery

ActiveCN113244808AUnable to dischargeAvoid local overheatingRotary stirring mixersTransportation and packagingEngineeringStructural engineering

The invention discloses carbonization equipment for processing a silicon-carbon negative electrode material of a lithium ion battery. The carbonization equipment comprises a box body mechanism, a stirring mechanism rotationally connected to the box body mechanism, a spraying mechanism fixedly connected to the inner upper side of the the box body mechanism, a fixed support fixedly connected to the inner lower side of the box body mechanism and a weighing plate arranged between and slidably connected with the box body mechanism and the fixed support, wherein the spraying mechanism is in transmission connection with stirring mechanism; a wall scraping mechanism and a limiting mechanism are arranged on the stirring mechanism; a drying mechanism is rotationally connected to the fixed support; the drying mechanism is in transmission connection with the stirring mechanism; and a first spring is arranged between the weighing plate and the box body mechanism. According to the invention, the wall scraping mechanism is driven by the gravity of materials to make contact with the inner wall of the box body mechanism, so a solvent or a coating material on the inner wall of the box body mechanism is scraped off in a rotating process, and the situation that the solvent or the coating material is attached to the inner wall of the box body mechanism and cannot be discharged is prevented.

Owner:HUNAN JIUHUA CARBON HI TECH

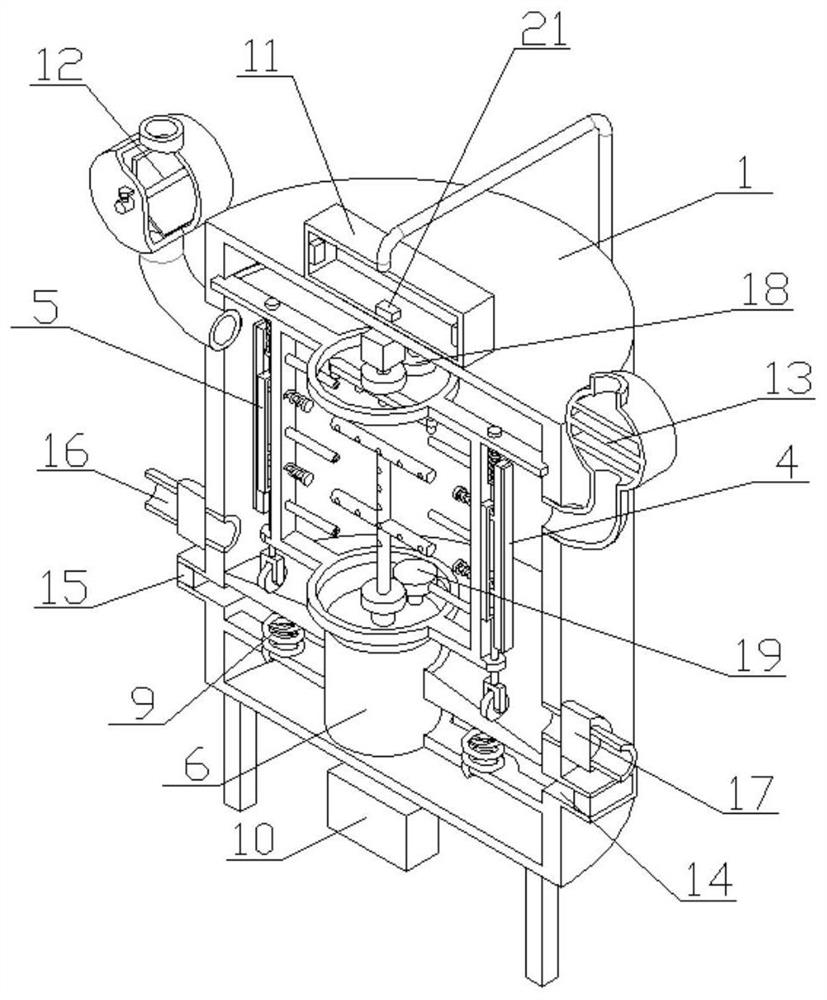

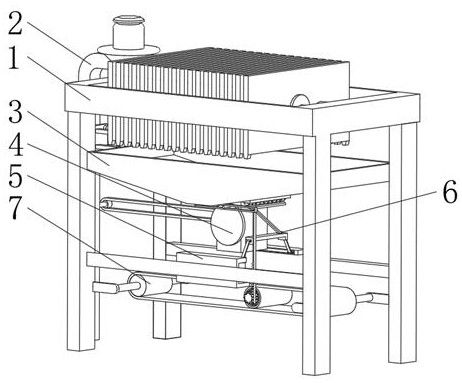

Flour processing, blending and mixing machine

InactiveCN110052206AUniform feedingEasy dischargeShaking/oscillating/vibrating mixersFlow mixersAdditive ingredientEngineering

The invention relates to a mixing machine, in particular to a flour processing, blending and mixing machine. By the flour processing, blending and mixing machine, uniform mixing is realized, materialsare prevented from being left at corners of containers, and flour on walls of containers can be automatically knocked. The flour processing, blending and mixing machine comprises a bottom plate, support plates, guide rails, guide blocks, a collection basket, a support, a first bearing block, a first rotating shaft, a disc, a support rod, a connection rod, a crow wheel, a motor and the like. The support plates are arranged at front and rear ends of left and right sides of the top of the bottom plate. The guide rails are arranged between the tops of the left support plate and the right supportplate on the front and rear sides. The guide blocks are arranged at the tops of the guide rails. The collection basket is arranged at the tops of the front and rear guide blocks. The flour processing,blending and mixing machine has the advantages that the feeding amount of a storage bucket can be controlled by a control device, so that low mixing efficiency caused by mixing non-uniformity due toexcessive feeding of flour and ingredients, or caused by influences on the mixing speed due to insufficient feeding, can be avoided.

Owner:胡世鹏

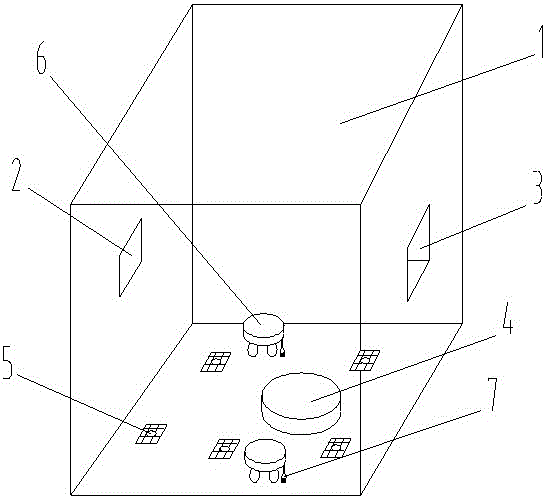

Cleaning room with plurality of sweeping robots for draining sewage

The invention discloses a cleaning room with a plurality of sweeping robots for draining sewage. The cleaning room comprises a cleaning room body, wherein a cleaning robot is arranged at the center of the cleaning room body; the bottom part of the cleaning robot is fixedly arranged on a worktable; the ground of the bottom part of the cleaning room body is provided with a plurality of water drainage floor drains; the plurality of movable sweeping water-drainage robots are arranged in the cleaning room body; movement rollers are arranged at the bottom end of each movable sweeping water-drainage robot, and a water-drainage sweeping brush is arranged at one end of each movable sweeping water-drainage robot, and is used for sweeping sewage on the ground of the cleaning room body into the water drainage floor drains through the movement of the corresponding movable sweeping water-drainage robot. By adopting the manner, the cleaning room has the advantages that by providing the sealed type cleaning room, cleaning parts can be cleaned; the cleaning robot is arranged in the cleaning room to match cleaning, and the movable sweeping water-drainage robots are also arranged in the cleaning room to sweep the sewage, generated after cleaning, into the water drainage floor drains.

Owner:无锡市湖昌机械制造有限公司

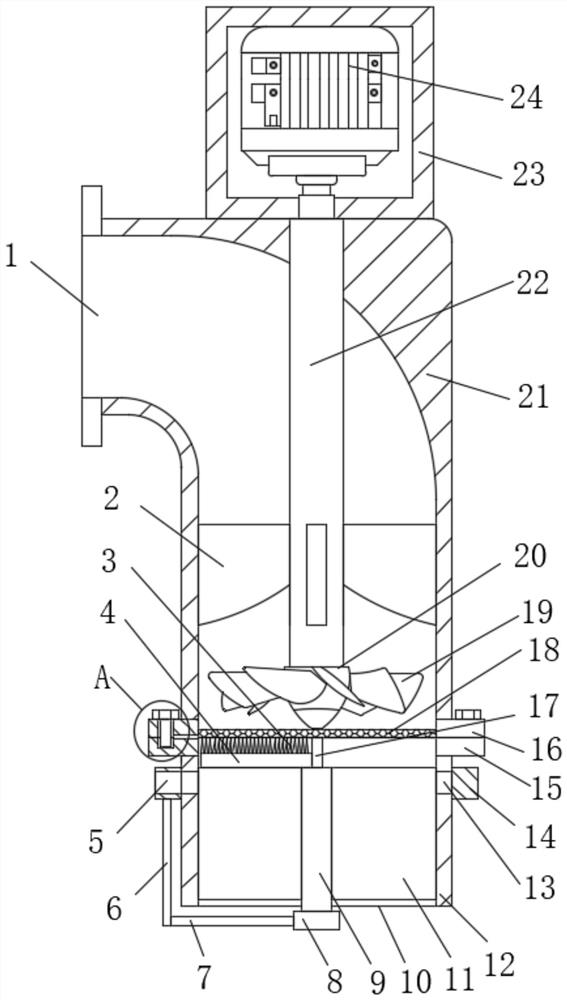

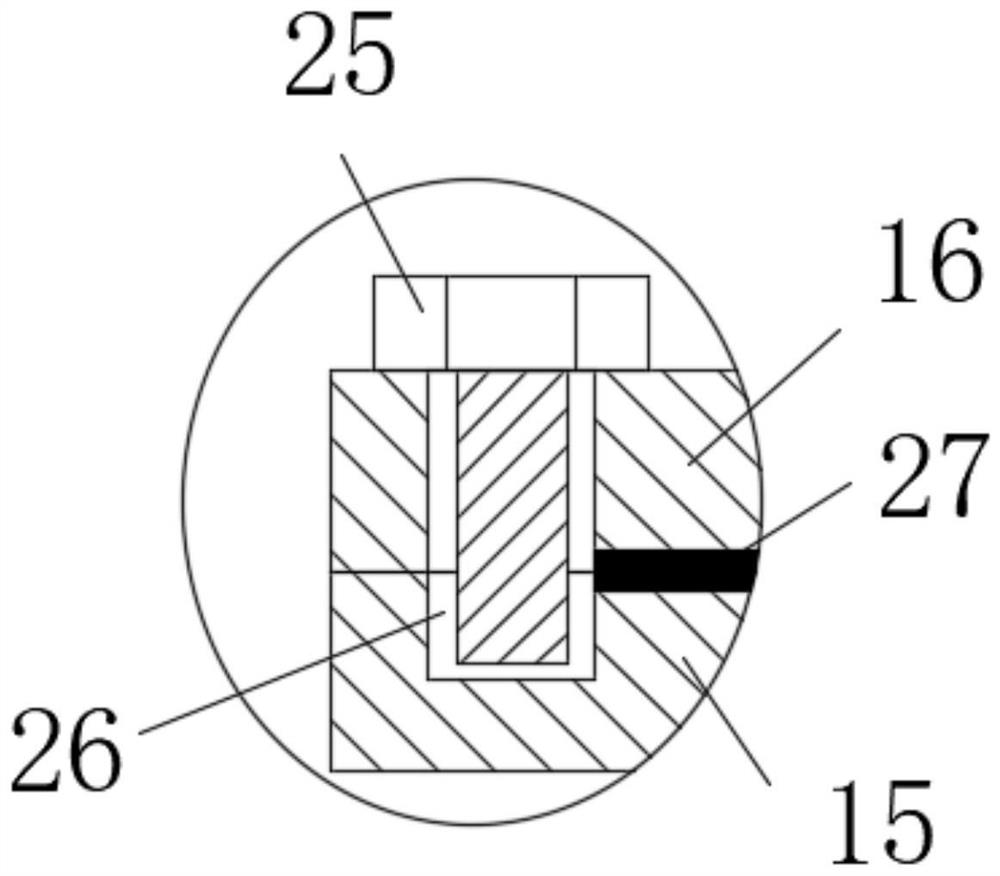

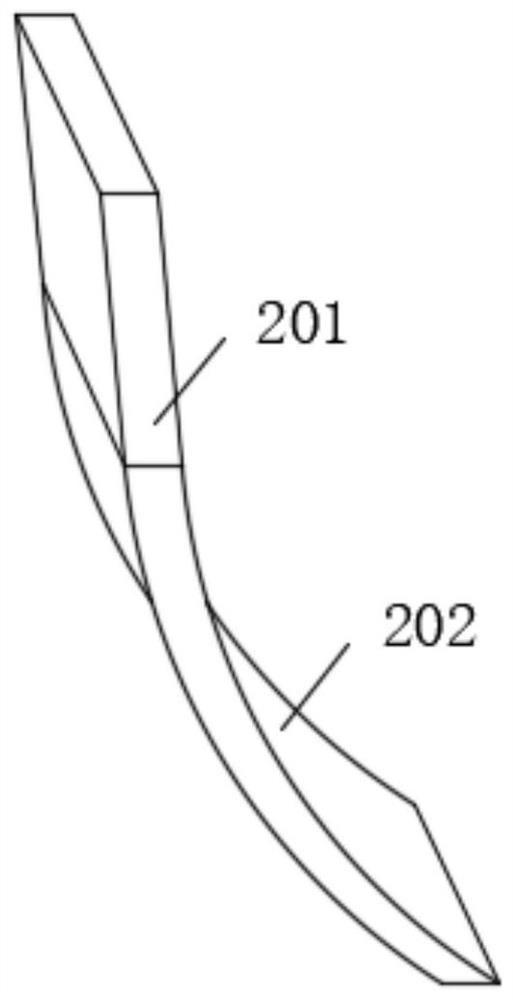

Axial-flow pump with anti-blocking function

ActiveCN113357161AEliminates rotational motionReduce lossesGeneral water supply conservationPump componentsAxial-flow pumpImpeller

The invention belongs to the field of axial-flow pumps, particularly relates to an axial-flow pump with an anti-blocking function, and provides the following scheme to solve the problems that existing axial-flow pumps are prone to jamming, part of the axial-flow pumps are internally provided with filter screens, but impurities under the filter screens are more and more and cannot be discharged, and then the water pumping efficiency is reduced. The axial-flow pump comprises a pump body and a connecting pipe, the connecting pipe is located below the pump body, connecting assemblies used for connection are arranged at the connecting pipe and the water inlet end of the pump body, a water inlet is formed in the bottom of the connecting pipe, and a water outlet is formed in one side of the pump body. According to the axial-flow pump, the water suction process is realized through an impeller; through arrangement of a first filter screen and a second filter screen, the filtering quality can be improved, and the pump is prevented from being blocked; through arrangement of an ash discharging port, impurities below the second filter screen can be continuously discharged, and the pump is prevented from being blocked; a guide vane can eliminate the rotating motion of water flow, and the water pumping efficiency is improved.

Owner:浙江理工泵业有限公司

Automatic raw material proportioning and mixing device

ActiveCN112847879AWell mixedRealize the role of quantitative feedingBLENDER/MIXERProcess engineering

The invention belongs to the technical field of plastic film production equipment, and particularly relates to an automatic raw material proportioning and mixing device. The automatic raw material proportioning and mixing device comprises a stirring barrel, a stirring mechanism and a plurality of storage tanks; a plurality of discharge ports with different sizes are formed in the side wall of the upper part of the stirring barrel; a discharge pipe is connected between each storage tank and one of the discharge ports; an inclined groove is formed in the inner wall of the stirring barrel; a sealing plate is arranged in the stirring barrel; and a protrusion connected to the inclined groove in a sliding mode is arranged on the sealing plate; a reset piece for sealing the sealing plate at the discharge port is connected between the sealing plate and the inner wall of the stirring barrel; the stirring mechanism comprises a stirring shaft, a driving piece, and a push rod and stirring blades, wherein the driving piece is used for driving the stirring shaft to rotate, and the push rod and the stirring blades are fixed on the stirring shaft; a protruding block capable of making contact with the push rod is arranged on the sealing plate; and when the sealing plate moves to the limiting position along the inclined groove, the push rod is disengaged from the protruding block. By using the technical scheme, the steps of mixing operation can be simplified, the efficiency is improved, the time of mixing operation is saved, and the raw material mixing uniformity can be improved.

Owner:CHONGQING RUITING PLASTIC

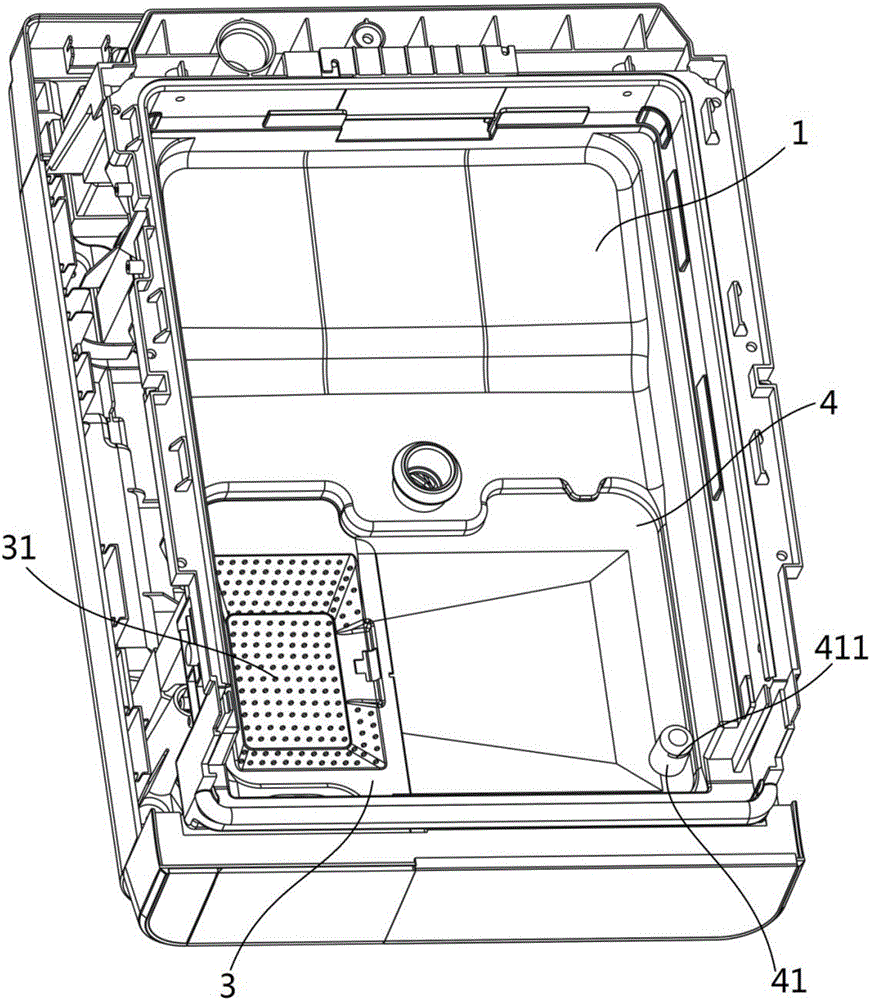

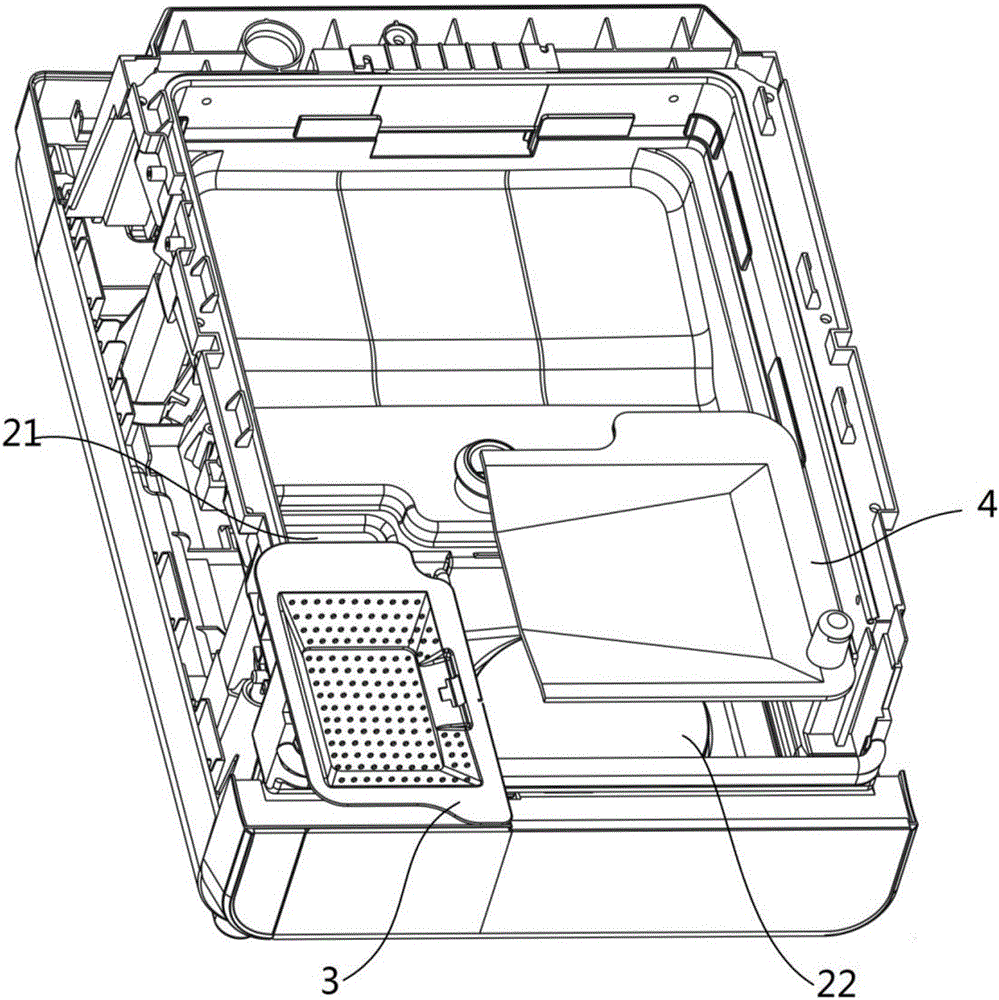

Dishwasher convenient to filter

ActiveCN107174179AReduce areaResolve shortness of breathTableware washing/rinsing machine detailsWater collectionCirculating pump

The invention provides a dishwasher convenient to filter. The dishwasher comprises an inner container, a water collection tank and a circulating pump are arranged on the lower portion of the inner container, and a water inlet of the circulating pump is arranged on the lower portion of the water collection tank; the water collection tank comprises a filter tank and a gas overflowing tank, a filter plate covers the top of the filter tank, a gas overflowing tank covering plate covers the top of the gas overflowing tank, and the gas overflowing tank is communicated with the filter tank; multiple filter holes are formed in the filter plate, an air exhausting column is arranged on the gas overflowing tank covering plate, an air exhausting hole is formed in the air exhausting column, and the air exhausting hole is communicated with the gas overflowing tank. As the gas overflowing tank has a certain volume, air in the water collection tank is allowed to be slowly exhausted through the air exhausting column on the gas overflowing tank covering plate, the problems that in the prior art, air exhaust is urgent and the air exhausting hole is likely to block are solved, and the dishwasher is safer and more reliable.

Owner:JOYOUNG CO LTD

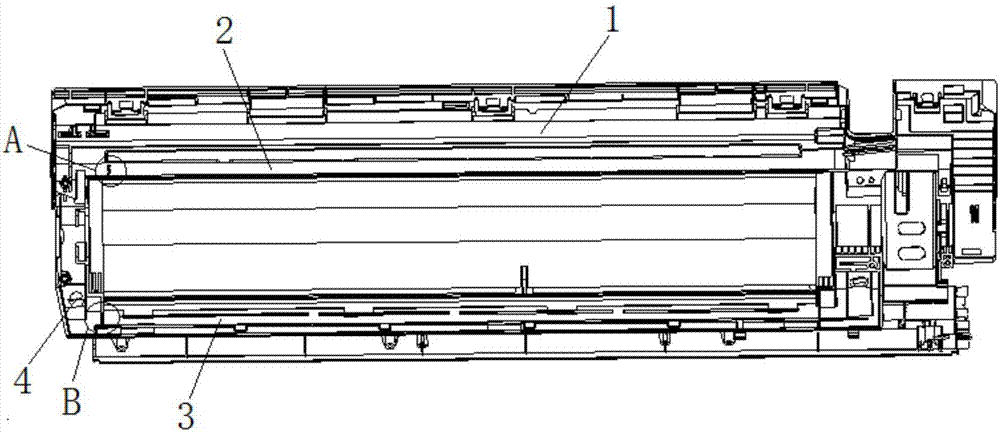

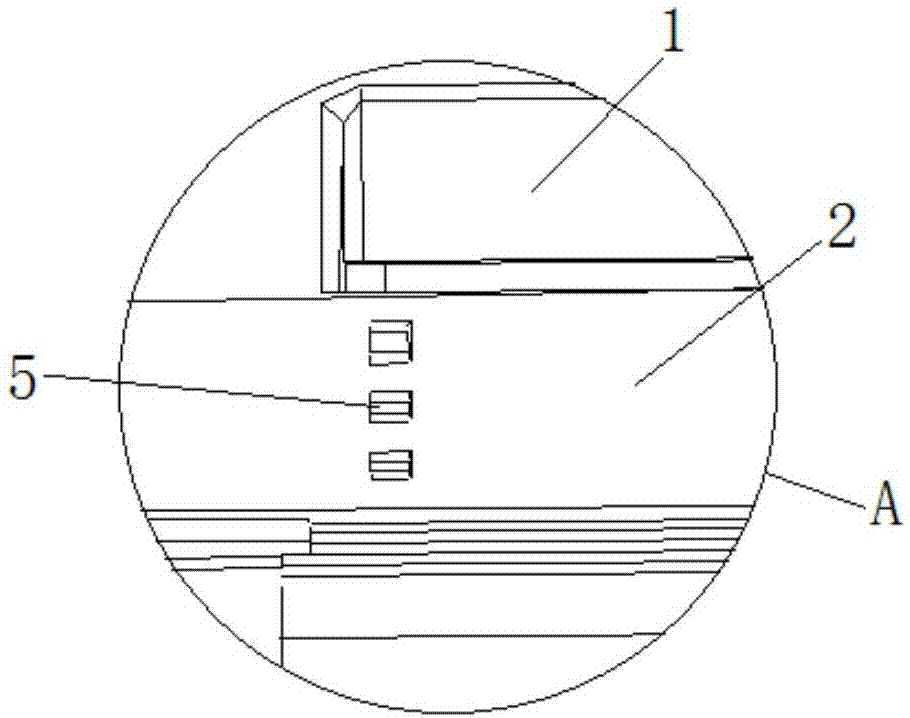

Air conditioner shell drainage structure and air conditioner

InactiveCN107965901AAvoid enteringSmooth dischargeCondensate preventionLighting and heating apparatusWater leakageEnvironmental engineering

The invention provides an air conditioner shell drainage structure and an air conditioner. The drainage structure comprises a shell; a drainage way is formed in the shell, and is used for collecting condensed water; the drainage way is provided with a stop structure; the drainage way communicates with a drainage pipe; and the stop structure is used for stopping impurities form entering the drainage pipe. As the technical scheme is adopted, under the condition of guaranteeing smooth passing of the condensed water of the air conditioner, such impurities as large-diameter indissoluble blocks cannot pass through; and the stop structure cannot influence normal drainage of the condensed water when stopping the impurities, so that the quality problems such as water leakage caused by filth blockage of the drainage pipe after installation of the air conditioner are prevented.

Owner:GREE ELECTRIC APPLIANCES INC

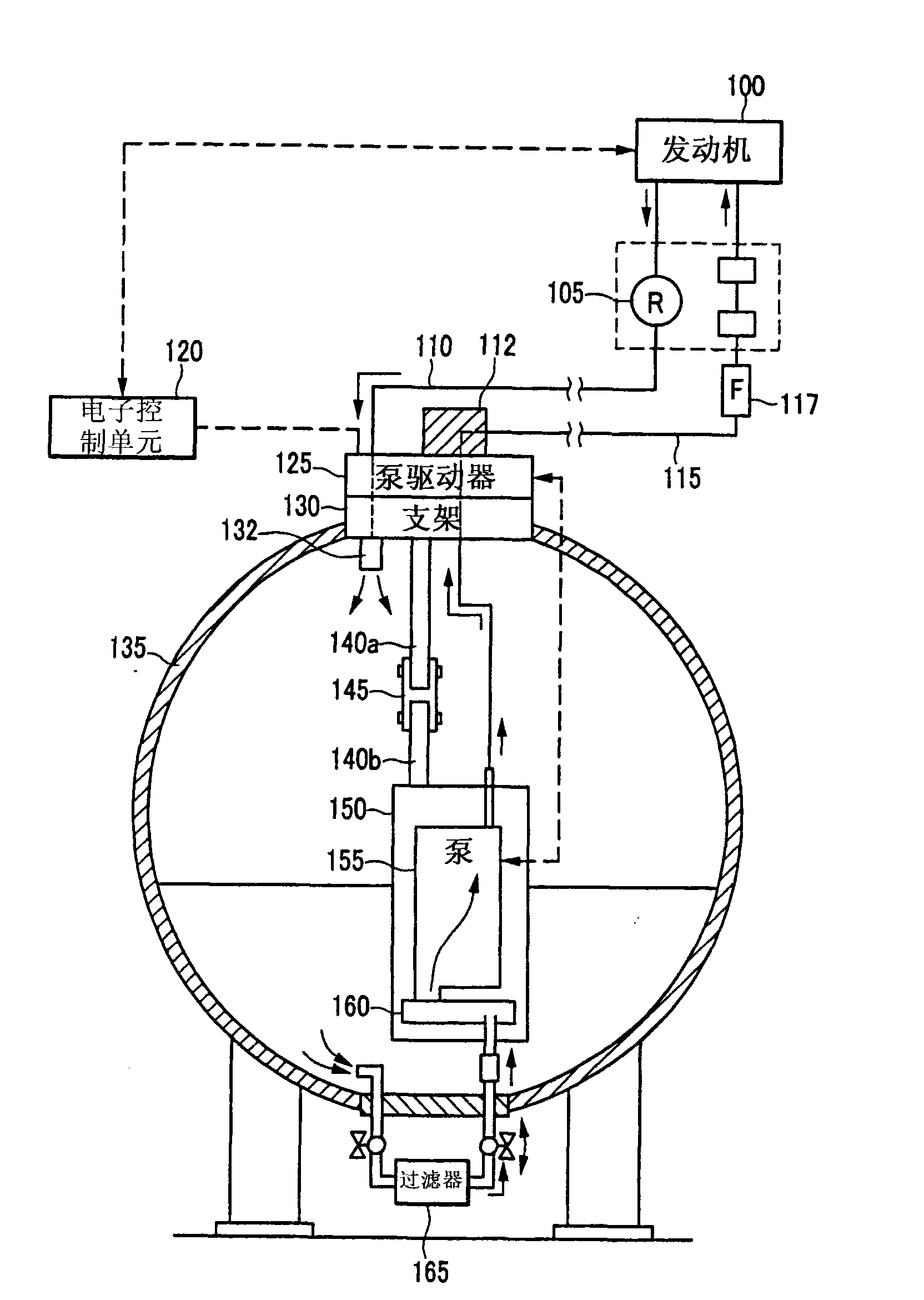

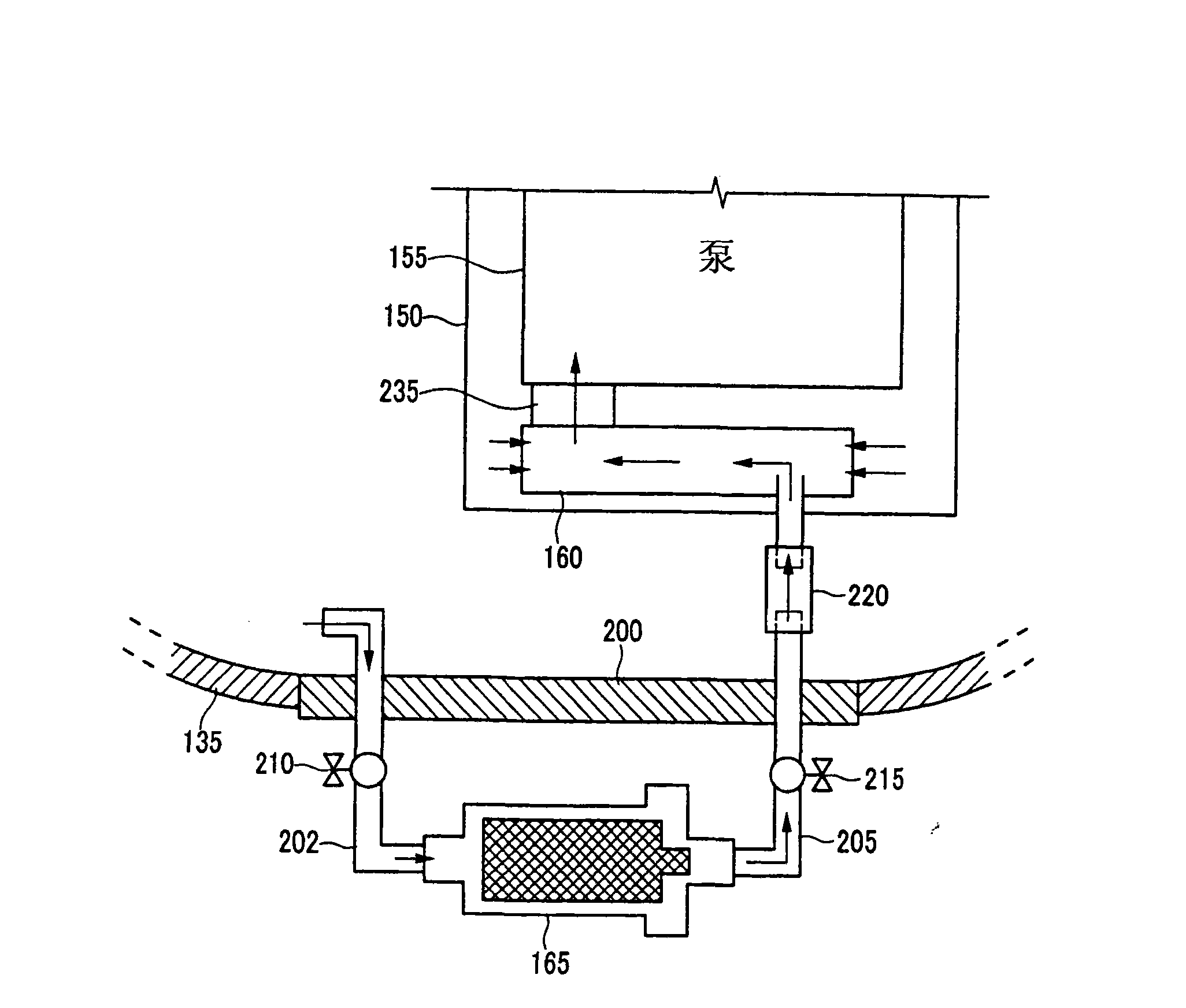

Liquefied petroleum fuel-injection feeding system

InactiveCN101634258AReduce suction resistanceAvoid passingInternal combustion piston enginesFuel supply apparatusPetroleumForeign matter

The present invention relates to a liquefied petroleum fuel-injection feeding system for feeding liquefied petroleum gas fuel to an engine, which can comprises a fuel tank filled with liquefied petroleum gas, a pump device arranged at the inner part of the fuel tank and used for feeding liquefied petroleum gas fuel to an engine, and an outer filter arranged at the outer part of the fuel tank and used for filtering foreign matters when the liquefied petroleum gas fuel is adsorbed into the pump device. Therefore, the outer filter can be changed without opening the fuel tank. In addition, when the outer filter is changed, a first valve and a second valve are closed so that the fuel in the container can not be discharged to the outer part. In addition, a suction pipeline is inserted into a prefilter, thereby reducing the suction resistance. Furthermore, the suction pipeline is separated, and the separated parts are connected by flexible tubes, thereby preventing the vibration and noise generated by the pump from being transferred to the fuel tank.

Owner:HYUNDAI MOTOR CO LTD +1

Quick discharging filter press for crushing and processing cordierite

InactiveCN113797616AImprove work efficiencyUnloading inconvenienceFiltration separationCordieriteHollow cylinder

The invention discloses a quick discharging filter press for crushing and processing cordierite, and relates to the technical field of cordierite processing. The quick discharging filter press comprises a filter press, the left side of the filter press is communicated with a feeding mechanism, a discharging mechanism is arranged in the filter press, the right side of a hopper is slidably connected with a guide block through a guide groove, the front face of the guide block is connected with the back face of a telescopic protruding block plate, the telescopic protruding block plate comprises a hollow cylinder, and the top of the hollow cylinder is slidably connected with a connecting cylinder through an open groove. According to the quick discharging filter press for crushing and processing cordierite, inconvenience caused by different discharging quantities to subsequent processing is prevented, a collecting barrel is automatically conveyed out through a conveying mechanism, and an unfilled collecting barrel is conveyed to the position under a discharging mechanism for unloading, so that the working efficiency is improved, the collecting barrel is prevented from being filled with raw materials and the raw materials are prevented from leaking to the top of the conveying mechanism and causing economic loss, and wet conveyed materials are prevented from being blocked in the hopper, not being discharged and seriously influencing the subsequent processing efficiency.

Owner:怀化市华恒莫来石有限公司

rearview mirror

InactiveCN104129368BUnable to dischargePromote excretionVehicle cleaningOptical viewingGear wheelEngineering

The invention relates to a rear view mirror. The rear view mirror comprises a casing, wherein rear view mirror glass is arranged on the casing, a slide groove and a first through hole are formed in the casing, the inner part of the slide groove is connected with a windscreen wiper, a sensor is arranged on the windscreen wiper, a motor is arranged in the casing and is connected with a rotating shaft, a first gear is arranged on the rotating shaft, a second through hole is formed in the side surface of the casing, a tray is arranged in the casing, a connecting piece is arranged at the side of the tray, a fixing piece is arranged below the connecting piece, the connecting piece and the fixing piece are connected through an elastic assembly, a first connecting rod is arranged on the lower side surface of the tray, a second connecting rod is arranged at the side surface of the first connecting rod, the second connecting rod is connected with a second gear, a flange is arranged at the side surface of the second gear, and the flange is connected with a rubber strip of which the end part is connected with the windscreen wiper. For the rear view mirror disclosed by the invention, the tray is used for collecting rain, the second gear can move downwards by the change of the weight of the tray, the second gear and the first gear are matched to use, and the motor rotates to drive the windscreen wiper on the rear view mirror glass to repeatedly move up and down, so that the rain on the rear view mirror glass is cleaned.

Owner:YUYAO ELEVATOR AUTO PARTS

Fine milling device used for production and processing of flour and milling method of fine milling device used for production and processing of flour

InactiveCN112387392AFacilitates fine grinding operationsFacilitate the overall efficiency of processingGrain treatmentsMechanical engineeringSieve

Owner:宿州市超王面业有限责任公司

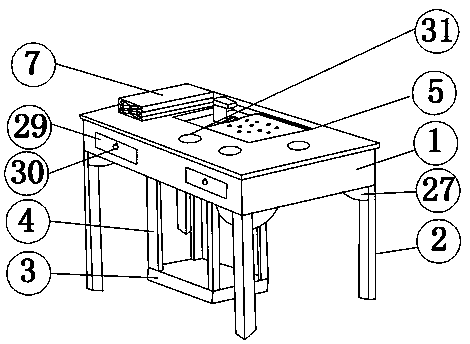

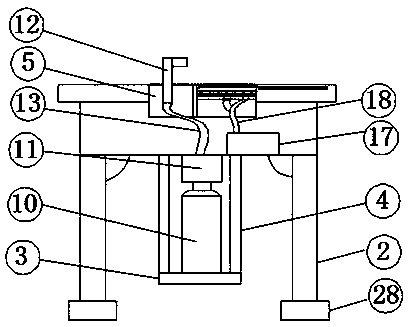

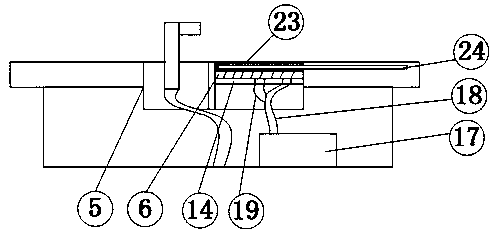

Tea table capable of saving space and facilitating tea brewing

The invention discloses a tea table capable of saving space and facilitating tea brewing. The tea table comprises a table body, wherein four corners of the table body are fixedly connected with supporting legs, wherein a supporting plate is arranged in a middle part below the table body; the supporting plate is fixedly connected with the table body by four first connecting rods; a drinking water mechanism is arranged on the supporting plate; a water draining mechanism is arranged on one side of the drinking water mechanism and is located inside the table body; a groove is formed in the centerof the top of the table body; a filtering plate is arranged inside the groove; a shielding mechanism is arranged above the filtering plate; a placing mechanism is arranged on one side of the groove, is located at the top of the table body and comprises a plurality of placing plates; scissor fork type arms are arranged on two sides of the placing plates; and two ends of the scissor fork type arms are movably connected with the placing plates by damper rotating shafts. The invention has beneficial effects that the tea table can automatically supply water; and the placing mechanism can place a plurality of tea leaves to reduce a space for occupying a table top and facilitating operation of brewing tea.

Owner:安徽爱就爱家具制造有限公司

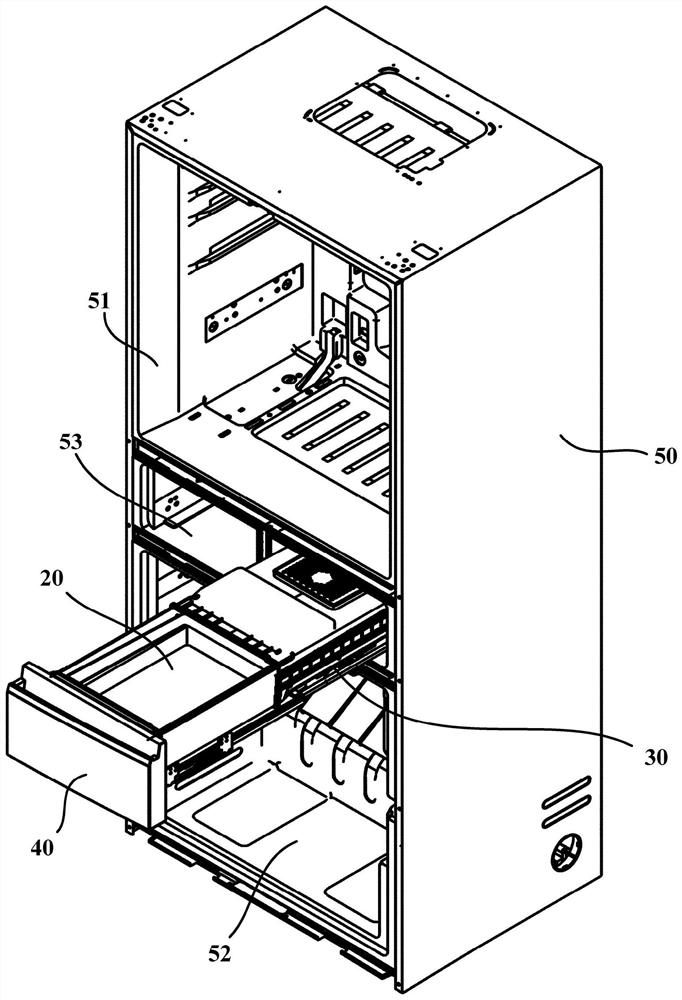

Refrigerator and control method thereof

PendingCN113494811AAffect the experienceImprove experienceLighting and heating apparatusDomestic refrigeratorsIceboxEngineering

The invention provides a refrigerator and a control method thereof. The refrigerator comprises a refrigerator body, a storage chamber is arranged in the refrigerator body, and a first air supply outlet and a second air supply outlet are arranged on the rear wall of the storage chamber; a storage device which is arranged in the storage chamber, a storage space is defined in the storage device, and a communication opening is arranged on the storage device; an air guide device, wherein the rear end of the air guide device is connected to the first air supply outlet, and the front end of the air guide device is configured to supply air to the front portion and / or the front portion of the storage device; a moisture-permeable device which is mounted at the communicating opening, so that moisture in the storage space permeates to the outer side of the storage space in a one-way manner through a moisture-permeable film; a humidity detection device which is configured to detect the humidity in the storage space and / or the humidity outside the storage space and in the storage chamber; an air path system which comprises an air supply duct communicated with the first air supply outlet and the second air supply outlet, a first air door for opening and closing the air guide device, and a second air door for opening and closing the second air supply outlet; and an air supply device is arranged in the air path system.

Owner:QINGDAO HAIER REFRIGERATOR CO LTD +1

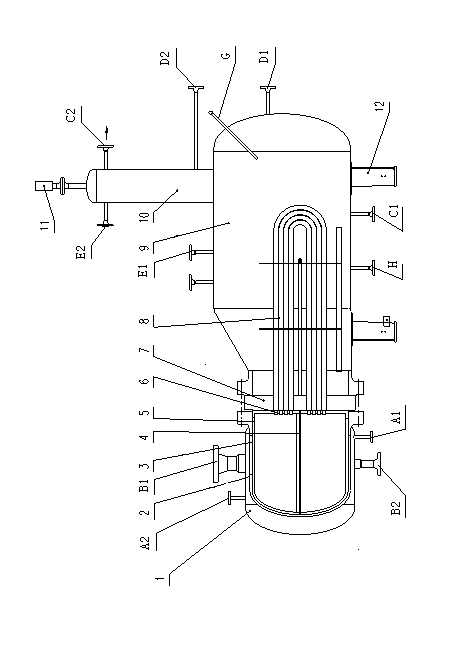

Substitute natural gas reaction heat recovery device

ActiveCN103574568ASave energyAvoid geothermal effectSteam generation using hot heat carriersProcess engineeringProduct gas

The invention discloses a substitute natural gas reaction heat recovery device. The substitute natural gas reaction heat recovery device comprises a housing with internal U-shaped heat exchange tubes, the lower end of the housing is provided with a clean water inlet, the upper end of the housing is provided with a steam pocket, and one end of the housing is provided with a tube sheet; a tube box is arranged outside the tube sheet, the inner cavity of the tube box is divided by a pass partition plate into a high-temperature upper cavity and a low-temperature lower cavity; the U-shaped heat exchange tubes are arranged on the tube sheet and communicated with the high-temperature upper cavity and the low-temperature lower cavity of the tube box; the gas inlet end of the high-temperature upper cavity is communicated with a reaction gas inlet; the gas outlet end of the low-temperature lower cavity is communicated with a reaction gas outlet; a fire-resistant heat insulation lining and a heat-resisting protect cover are arranged inside the tube box. The substitute natural gas reaction heat recovery device solves the problem of heat recovery of high-temperature gas generated during the substitute natural gas production process; substitute natural gas reaction heat recovery and recycling saves energy sources and avoids earth heat effects due to massive high-temperature gas emitted into the air.

Owner:SHIJIAZHUANG GONGDA CHEM EQUIP

Soil quantitative fertilization device for agricultural production

PendingCN111264154AUnable to dischargeSpread evenlyWatering devicesFertiliser distributersAgricultural scienceAgricultural engineering

The invention belongs to the field of agricultural instruments, and especially relates to a soil quantitative fertilization device for agricultural production. The situations of agglomerating of existing fertilization devices are easy to occur, existing fertilization equipment cannot perform quantitative fertilization so as to make the fertilization process of crops uneven, and the irrigation anddilution of fertilizer cannot be simultaneously carried out during fertilization to promote the crops to further and rapidly absorb the nutrients in the fertilizer, so that the healthy growth of the crops is severely affected, and for the above-mentioned problems, the following schemes are provided: the fertilization device includes a shell; and one side of the shell is fixedly connected to a pushing handle, and a motor is fixedly installed on the other side of the shell. Through the arrangement of stirring rods, a water-draining gun and a push plate, the agglomerating of the fertilization device is not easy to occur, quantitative fertilization can be performed, the uniform fertilization of the crops can be achieved, and the irrigation and dilution of the fertilizer can be simultaneously performed during fertilization so as to promote the crops to further and rapidly absorb the nutrients in the fertilizer.

Owner:陈政民

Automatic monitoring and automatic quality control equipment for water environment

PendingCN114217040AReduce the impactGuaranteed accuracyWithdrawing sample devicesTesting waterQuality controlWater environment

The invention relates to the technical field of water environments, and discloses water environment automatic monitoring and automatic quality control equipment which comprises a sampling device and a detection mechanism arranged on the sampling device, the sampling device comprises a sampling box, the sampling box is divided into a first sampling bin and a second sampling bin through a partition plate, a communication groove is formed in the partition plate, and the first sampling bin and the second sampling bin are communicated through the communication groove. According to the water environment automatic monitoring and automatic quality control equipment, through the design of a regulation and control cylinder and a regulation and control box and the staggered arrangement of a first sliding groove and a second sliding groove, when the sampling box pumps water, a second piston firstly moves, meanwhile, a valve plate is driven to open a communicating groove, when the sampling box drains water, a first piston firstly moves, and then the sampling box drains water; meanwhile, the valve plate is driven to block the communicating groove, in the process, air in the first sampling bin can enter the second sampling bin as much as possible, meanwhile, it can be guaranteed that a certain amount of water is temporarily reserved in the first sampling bin, and timely reinspection can be conveniently conducted when needed.

Owner:浙江中环瑞蓝科技发展有限公司

Bubble removing machine for rectangular film-covered paper box

The invention provides a bubble removing machine for a rectangular film-covered paper box. The bubble removing machine structurally comprises a film covering roll, an assembly plate, a main body frame, a bubble remover and a supporting base. The outer walls of the two ends of the film covering roll are assembled on the inner walls of the two sides of the lower portion of the front end of the main body frame in a nested mode, and the rear end of the assembly plate is fixed to the upper portion of the front end of the main body frame through screws. When the bubble removing machine is used, a film is bonded to the film covering roll and attached to the surface of a carton needing film covering through the film covering roll, and the film covering roll carries the film and flatly lays the film on the surface of the carton through pushing of equipment. After attachment is completed, the bubble remover at the rear end can roll the attached film. During downward pressing, the bubble removing roll can move upwards due to counter-acting force, a rolling ring is supported through a booster arranged in the bubble removing roll in the moving process, and the rolling ring is better attached to the surface of the carton. The situation is avoided that as the structure of the carton is changed after the carton is stressed, the rolling ring cannot be completely attached to the surface of the carton, and air at the joint of the film and the carton cannot be completely exhausted.

Owner:陈克华

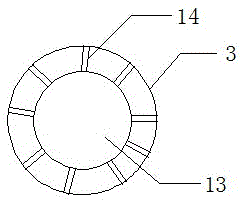

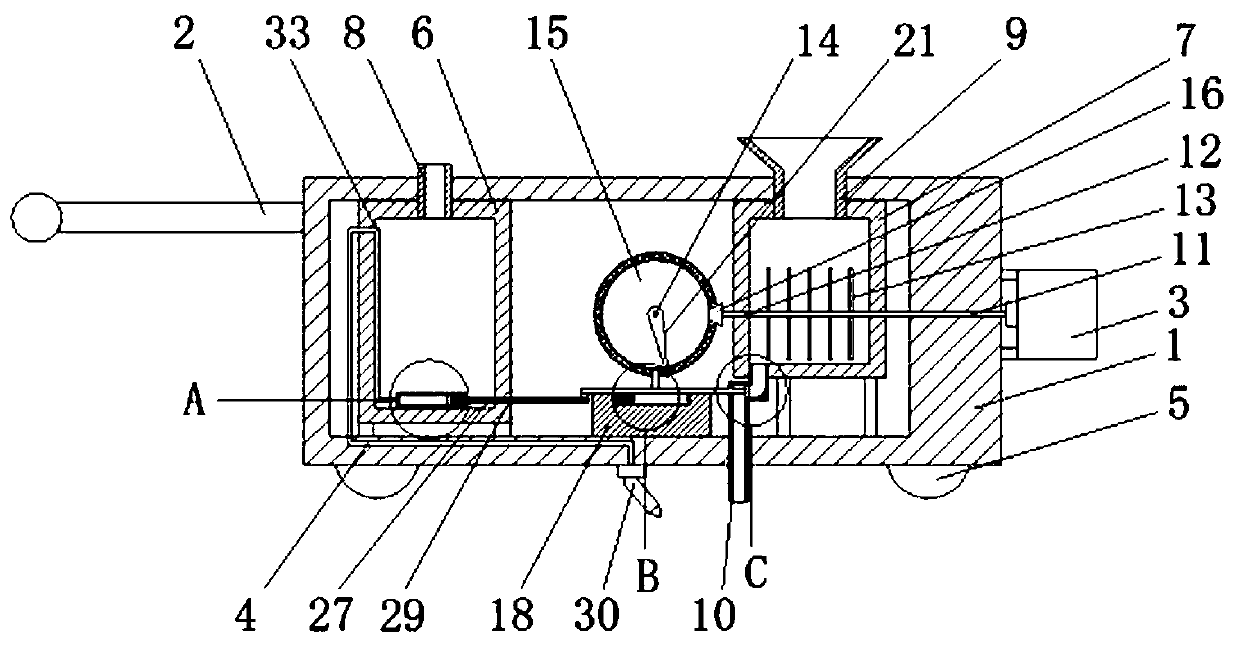

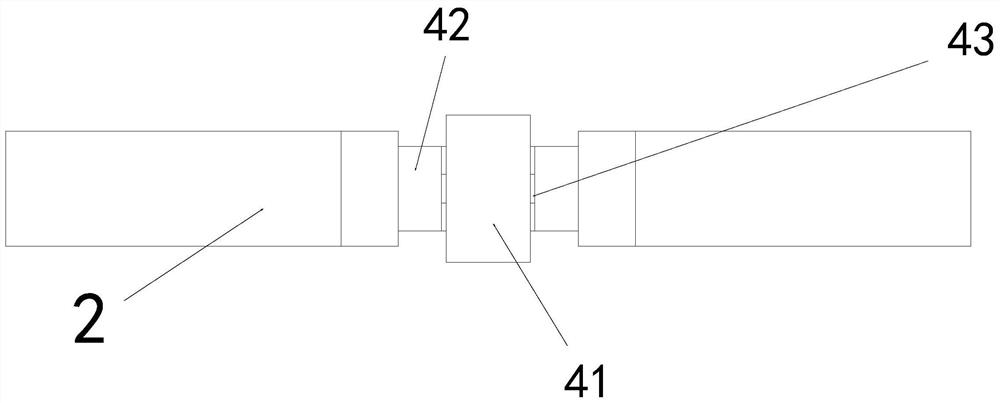

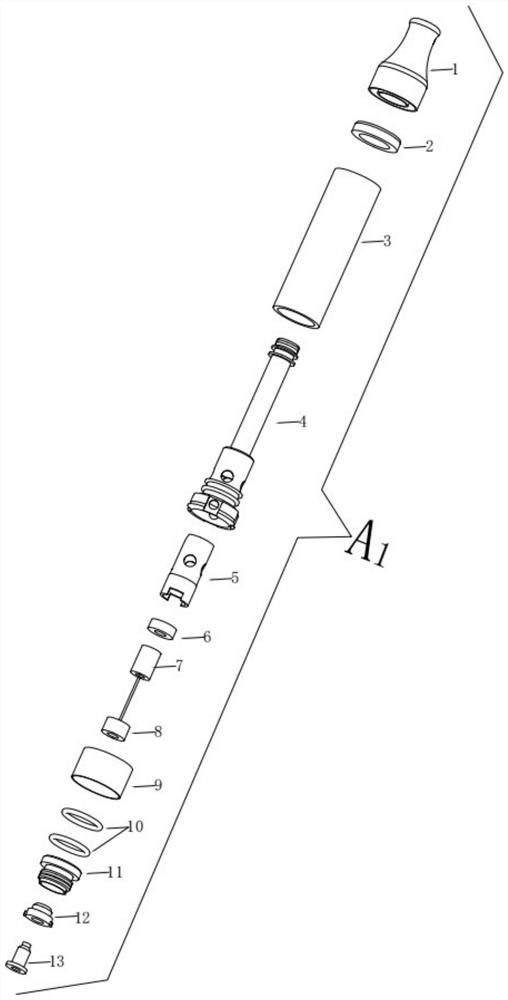

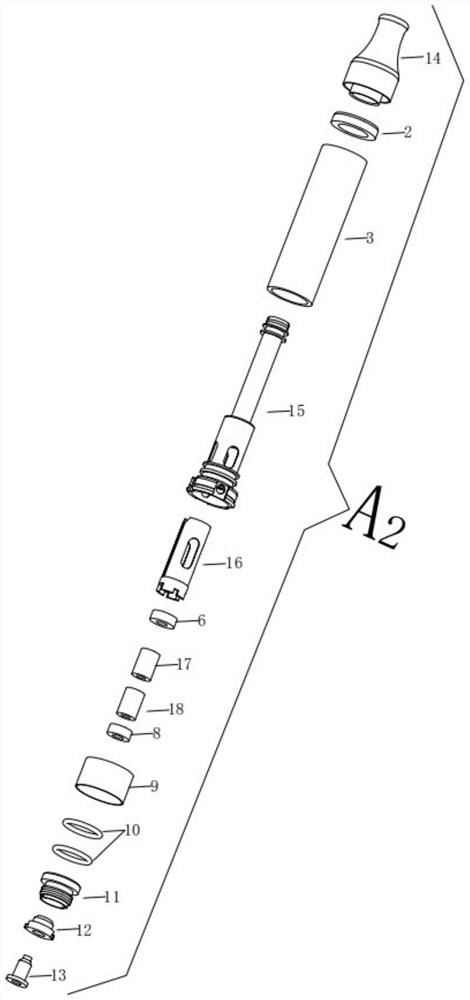

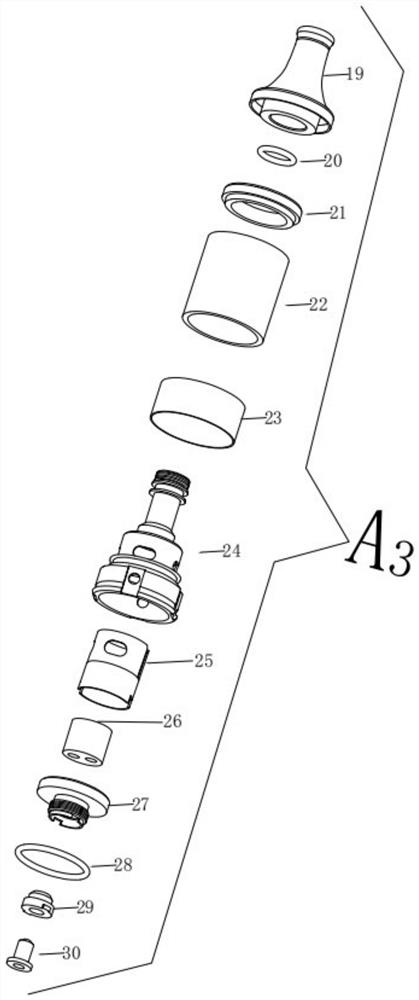

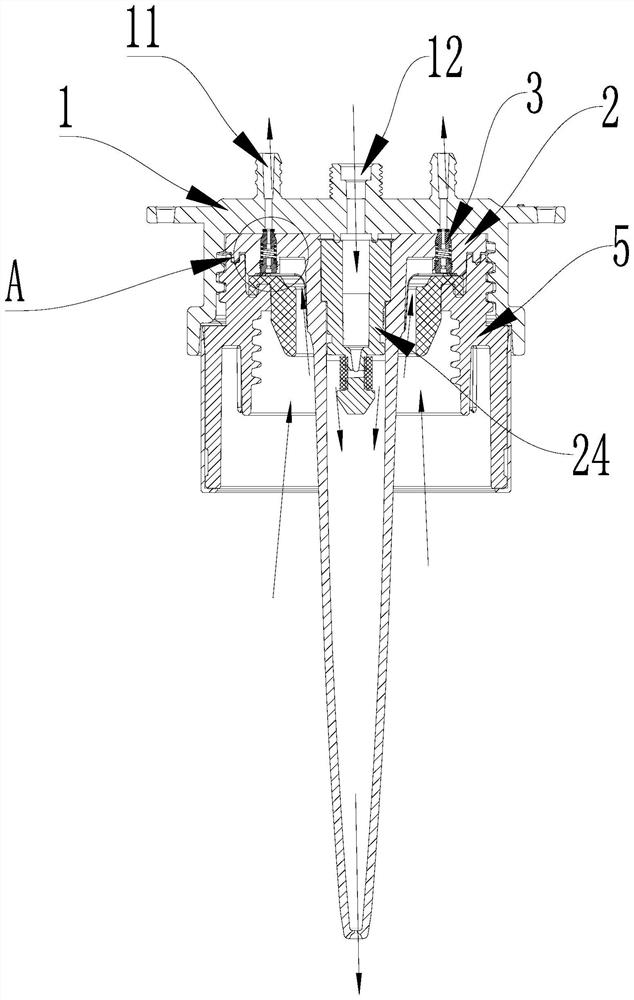

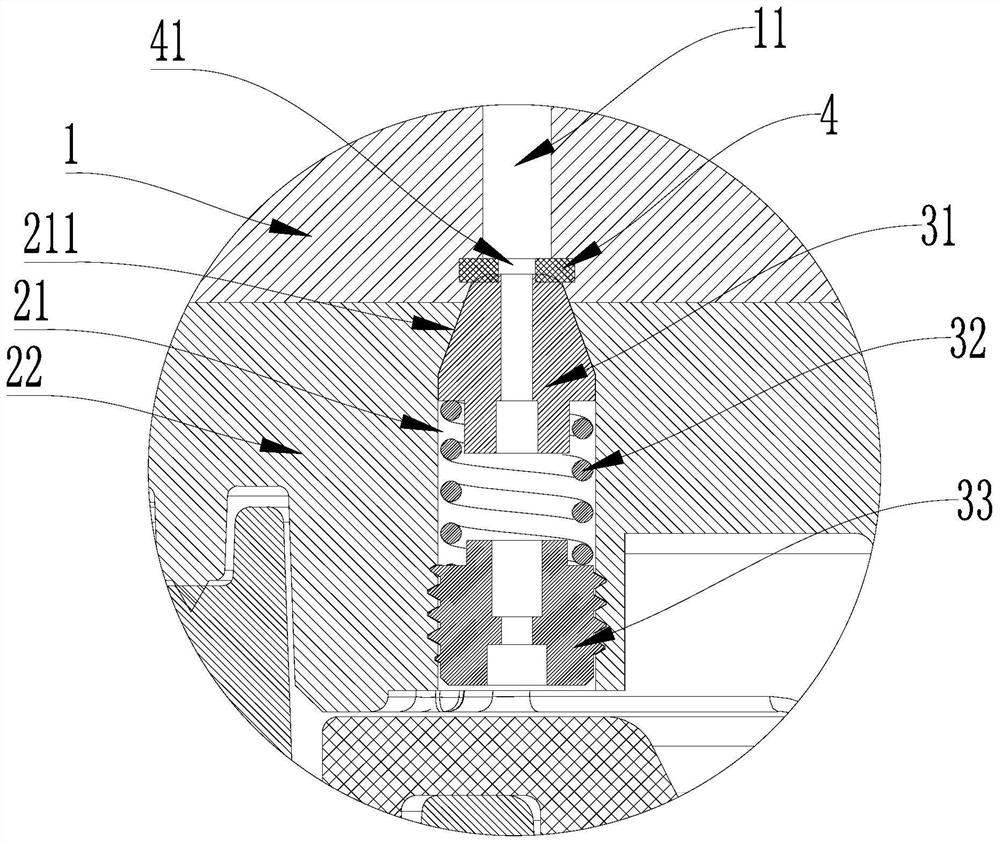

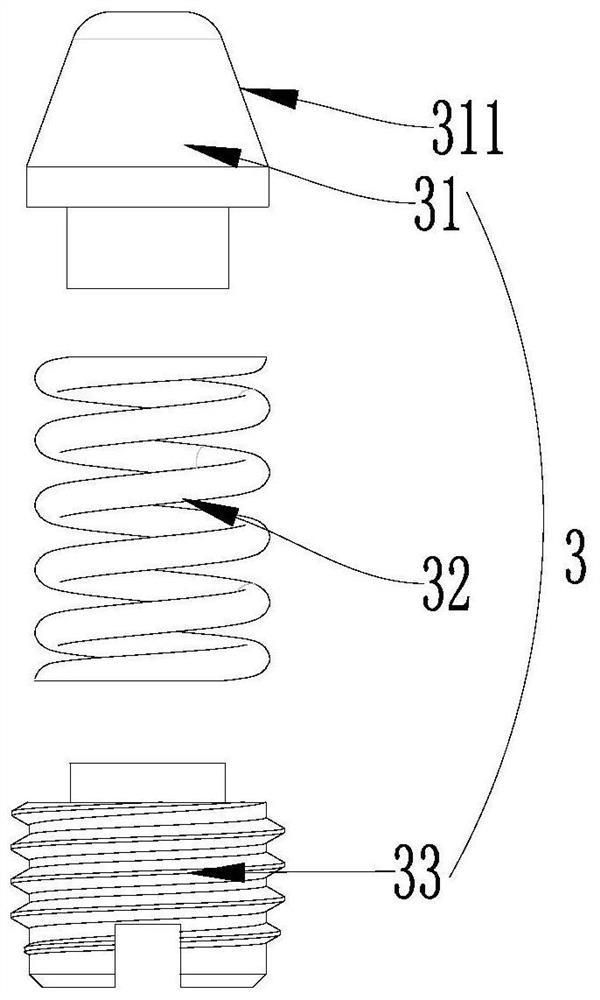

Ceramic multi-type single-heating-wire and double-heating-wire connected split atomizer

The present invention provides a ceramic multi-type single-heating-wire and a double-heating-wire connected split atomizer. The atomizer (A1) comprises a first cigarette holder (1), a glass tube uppersealing ring (2), a glass tube (3), a single-core atomizing rod (4), a ceramic core fixing seat (5), upper oil absorption cotton (6), a ceramic core (7), lower oil absorption cotton (8), a decorativering (9), a sealing ring (10), a base (11), an insulation ring (12) and an electrode (13). The glass tube upper sealing ring (2) is arranged at the bottom of the cigarette holder (1); and the first cigarette holder (1) is installed on the glass tube and then used for sealing a top opening of the glass tube (3), and then the sealing ring (10) is installed at the bottom of the single-core atomizingrod (4). The single-core atomizing rod (4) is installed on the glass tube from the bottom and then used for sealing a bottom opening of the glass tube (3), the upper oil absorption cotton (6) is placed on the top of the ceramic core (7), the lower oil absorption cotton (8) is installed on the bottom of the ceramic core (7), and then the upper oil absorption cotton and the lower oil absorption cotton are installed in the ceramic core fixing seat (5) to form a whole.

Owner:刘团芳

Bottleneck fixing structure of sparkling water machine, and sparkling water machine

The invention relates to a bottleneck fixing structure of a sparkling water machine, and the sparkling water machine. The bottleneck fixing structure of the sparkling water machine comprises a fixed seat, a nozzle and a sealing structure, wherein the fixed seat comprises an exhaust hole, and a first sealing slope is arranged on the hole wall of the exhaust hole; the nozzle is connected with the fixed seat, a first through hole communicating with the exhaust hole is formed in the nozzle, and a second sealing inclined surface is arranged at the position, close to the fixed seat, of the hole wall of the first through hole; the sealing structure is arranged in the first through hole and comprises a pressing block and an elastic piece, a second through hole communicating with the exhaust hole is formed in the pressing block, and a third sealing slope matched with the first sealing slope and the second sealing slope is arranged on the peripheral wall of the pressing block; and the elastic piece is connected with the pressing block and is suitable for providing elastic force towards the direction of the fixed seat for the pressing block, and a third through hole communicating with the second through hole is formed in the elastic piece. According to the bottleneck fixing structure of the sparkling water machine provided by the invention, the sealing structure ensures that gas can only be exhausted from an exhaust port.

Owner:GREE ELECTRIC APPLIANCES INC

A can compression device for waste recycling based on torsion extrusion

ActiveCN109049813BPlay a torsion roleSolve the problem that cannot be discharged normallyPressesWaste productCompression device

The invention discloses a ring-pull can compressing device for waste recycling based on torsion extrusion, and relates to the technical field of ring-pull can compression. The ring-pull can compressing device for waste recycling based on torsion extrusion comprises a first shell, wherein a support plate is fixedly connected to the inner wall of the first shell; first guiding rods are fixedly connected to the left side and the right side of the inner wall of the support plate; first moving mechanisms sleeve on the surfaces of the first guiding rods; and the surfaces of the first moving mechanisms are slidably connected with the surface of the support plate. According to the ring-pull can compressing device for waste recycling based on torsion extrusion, a ring-pull can is stressed by the torsion action so as to be inwards contracted during the compression process, and the phenomenon that the ring-pull can is expanded outwards so as to be incapable of being normally discharged when beingcompressed is avoided, so that the problems that at present, the ring-pull can is easy to outwards expand when the ring-pull can compressing device is used for compressing the ring-pull can so as tobe irregular in shape, and the compressed ring-pull can cannot be discharged normally are effectively solved.

Owner:绍兴市览海环保科技有限公司

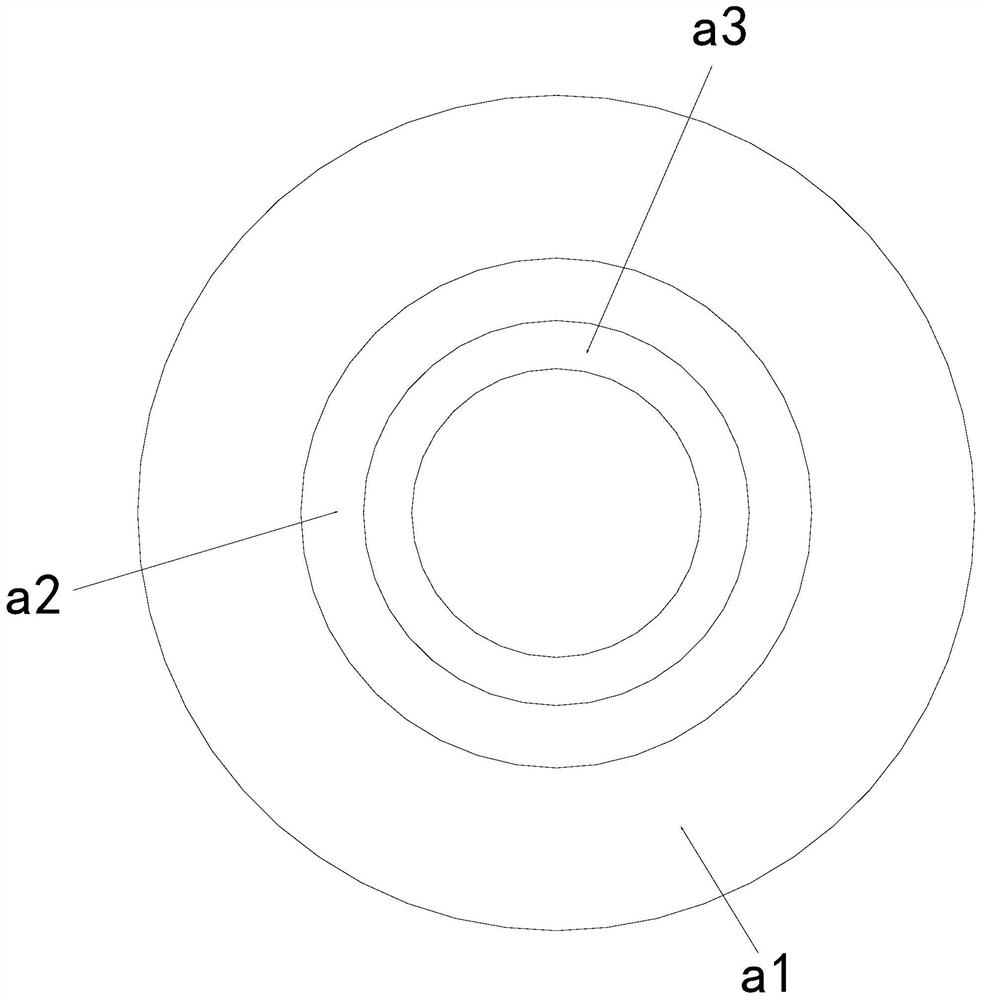

Welding method of semiconductor device and semiconductor device

ActiveCN112992691AReduce the overall heightReduce spacingSemiconductor/solid-state device detailsSolid-state devicesDevice materialEngineering

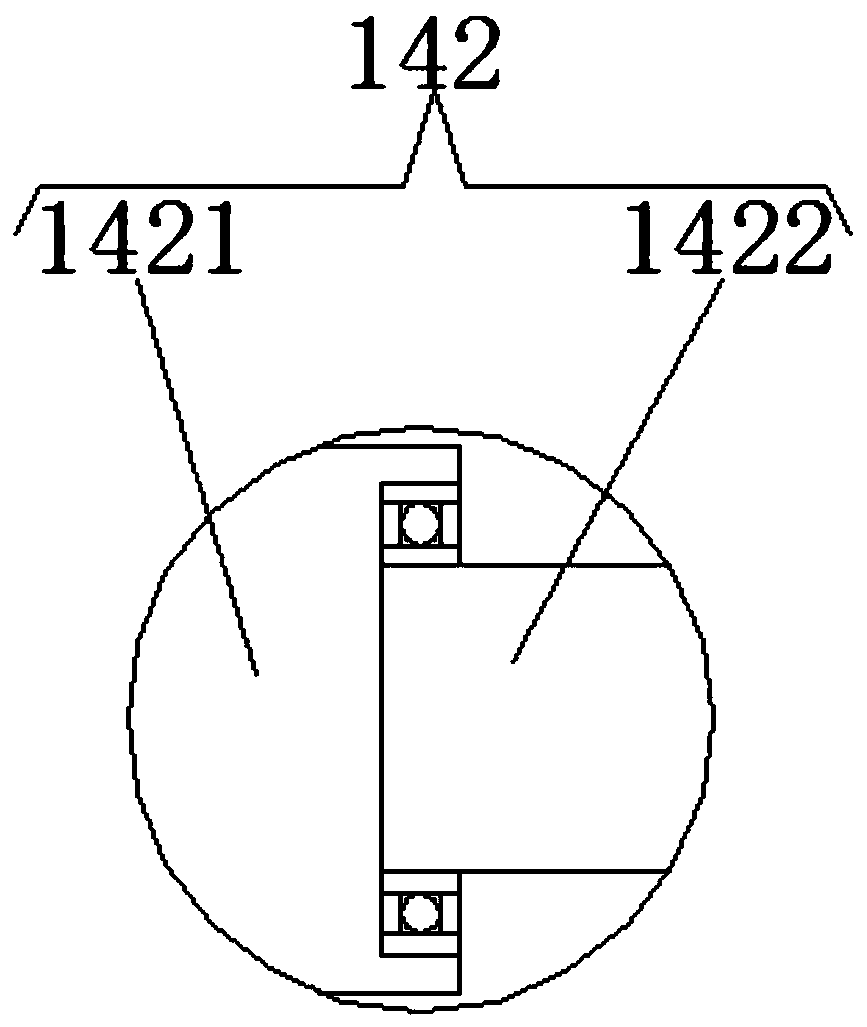

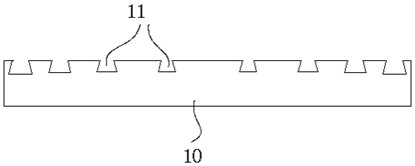

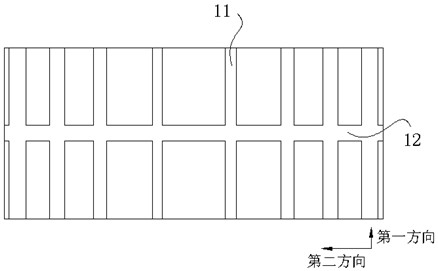

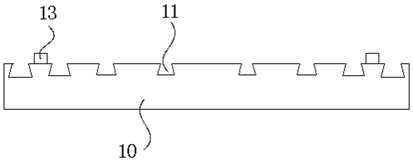

The invention provides a welding method of a semiconductor device and a semiconductor device, and belongs to the technical field of semiconductor device preparation. The welding method comprises the following steps that a groove structure is set: a plurality of first grooves which extend along a first direction and are arranged at intervals along a second direction are formed on the surface of a first device; a solder is deposited; a solder structure is deposited on the surface of the first device, a plurality of protruding parts which extend in the first direction and are arranged at intervals in the second direction are formed on the surface of the solder structure, and the heights of the protruding parts are gradually reduced from the middle of the first device to the two sides of the first device in the second direction; the first device and a second device are welded; and the second device is placed on the solder structure, and the solder is heated, so that the second device can be soldered with the first device. In the welding process, the gaps between the adjacent protruding parts and the gap between the top faces of the protruding parts with the lower height and the second device can serve as exhaust channels, so that gas in the welding process is exhausted to the outside, cavities generated in a welded welding flux layer are reduced, and the void rate is reduced.

Owner:度亘核芯光电技术(苏州)有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com