Automatic raw material proportioning and mixing device

A technology of automatic proportioning and mixing device is applied in the field of plastic film production equipment, which can solve the problems of time-consuming and troublesome operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The following is further described in detail through specific implementation methods:

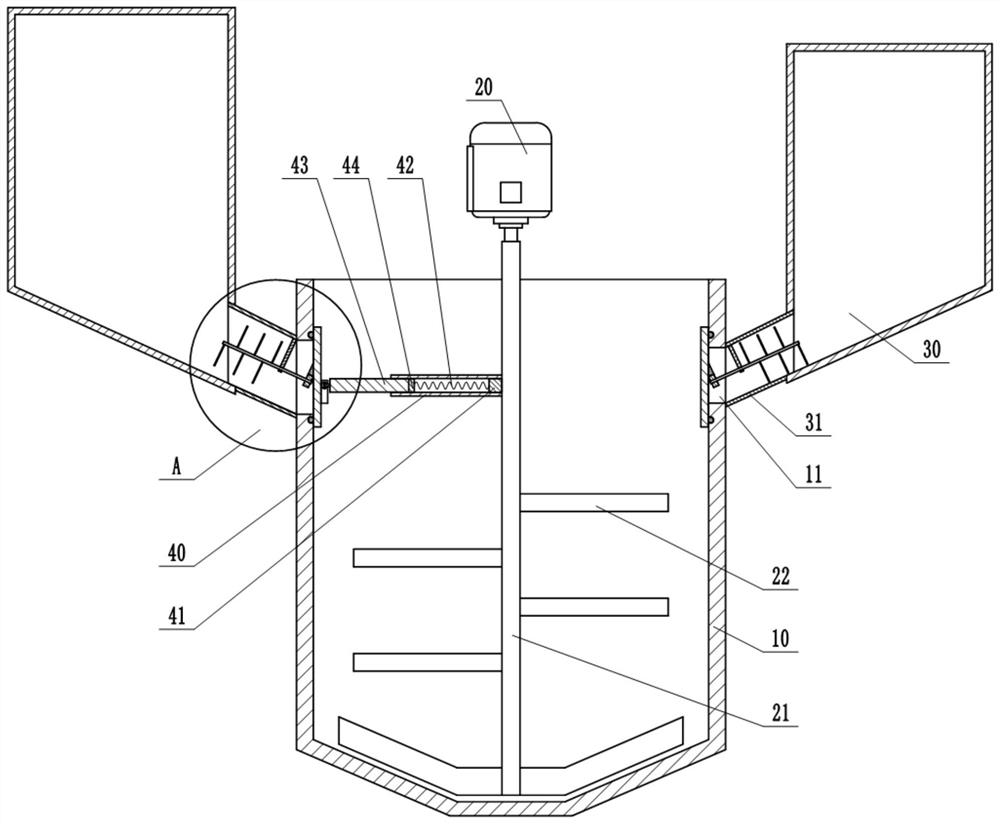

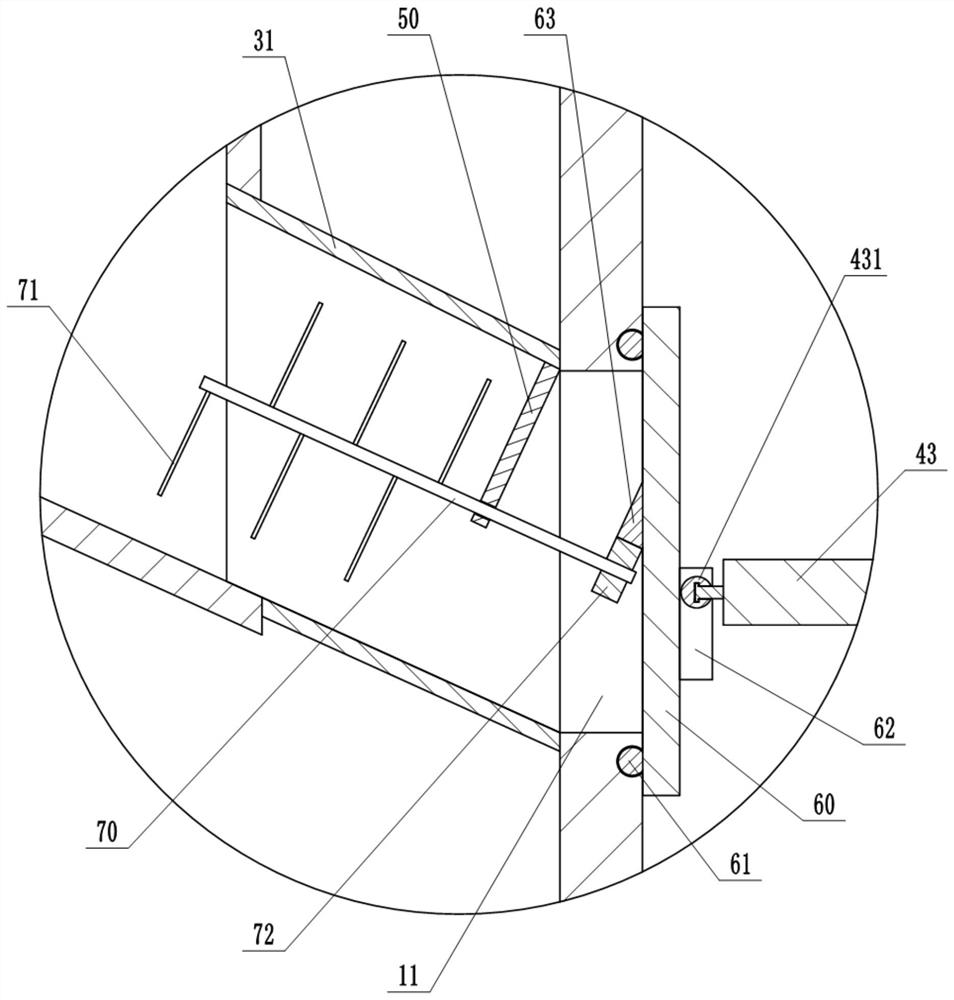

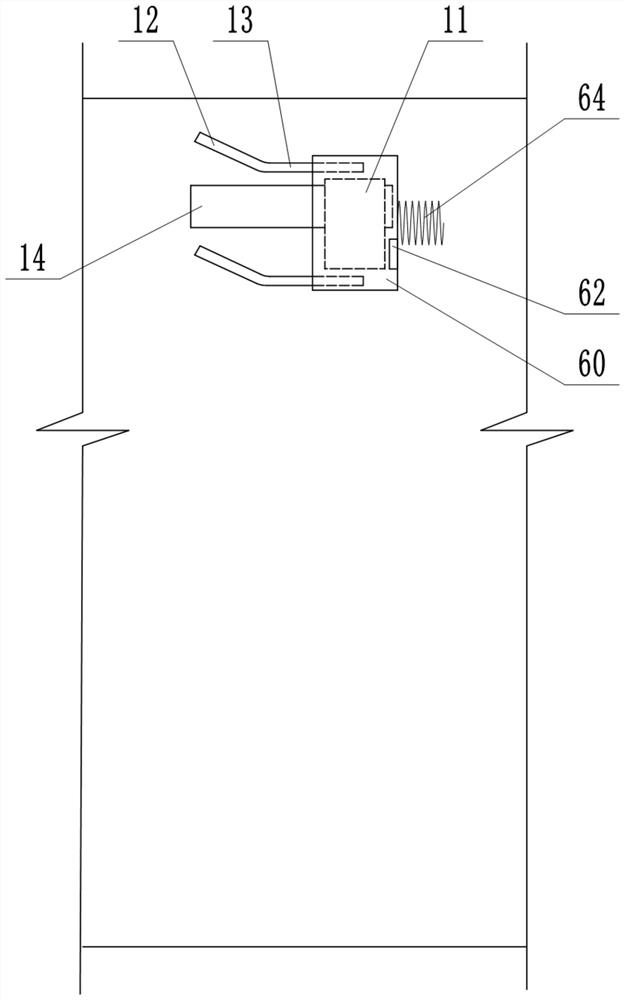

[0019] The reference signs in the drawings of the description include: mixing drum 10, discharge port 11, chute 12, horizontal tank 13, accommodating tank 14, motor 20, stirring shaft 21, stirring blade 22, storage tank 30, discharge Tube 31, fixed cylinder 40, electromagnet 41, elastic member 42, sliding rod 43, ball 431, iron block 44, bracket 50, sealing plate 60, protrusion 61, protrusion block 62, rack 63, reset member 64, Rotating shaft 70, stirring rod 71, gear 72.

[0020] This embodiment is basically as Figure 1-Figure 3 Shown: a raw material automatic proportioning and mixing device, including a frame, a mixing drum 10, a stirring mechanism and a plurality of storage tanks 30 installed on the frame, and a plurality of storage tanks 30 along the circumferential direction of the upper part of the mixing drum 10 Evenly distributed; the specific number of storage tanks 30 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com