Bubble removing machine for rectangular film-covered paper box

A film-coating and carton technology, applied in papermaking, paper/cardboard containers, container manufacturing machinery, etc., can solve problems such as cardboard sagging, incomplete lamination of film, structural deformation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

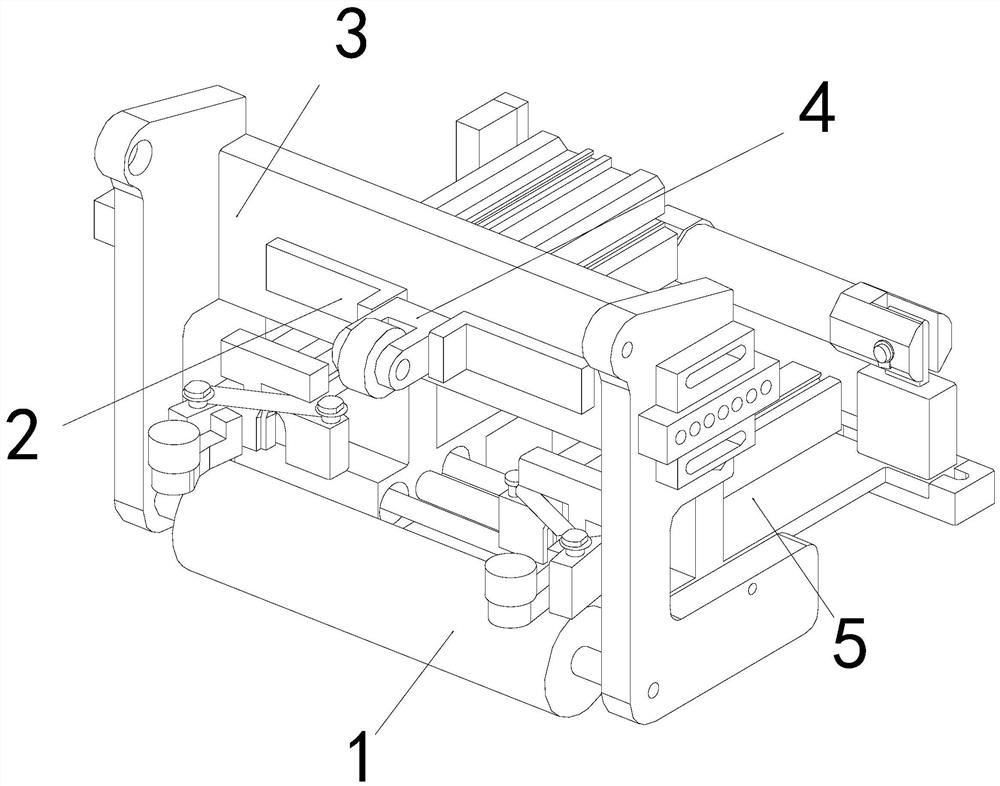

[0025] as attached figure 1 to attach Figure 4 As shown, the present invention provides a rectangular film-coated carton debubbling machine, its structure includes a film-coated roller 1, an assembly plate 2, a main body frame 3, a defoamer 4, a support seat 5, and the two ends of the film-coated roller 1 The outer wall is nested and fitted on the inner walls on both sides below the front end of the main frame 3, the rear end of the assembly plate 2 is fixed above the front end of the main frame 3 by screws, and the rear end of the main frame 3 is embedded and fixed on the front end of the support seat 5. Both sides of the rear end of the bubbler 4 are movably engaged between the assembly plates 2. There are two assembly plates 2 arranged opposite to the two ends of the defoamer 4. By assembling the two ends in parallel, the defoamer is prevented from 4 Offset during work;

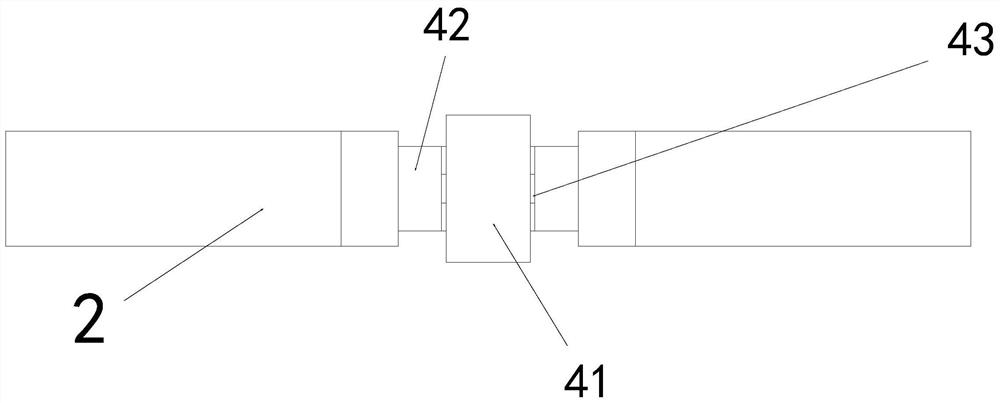

[0026] The defoamer 4 is composed of a foam rolling roller 41, an assembly seat 42, and a connecting...

Embodiment 2

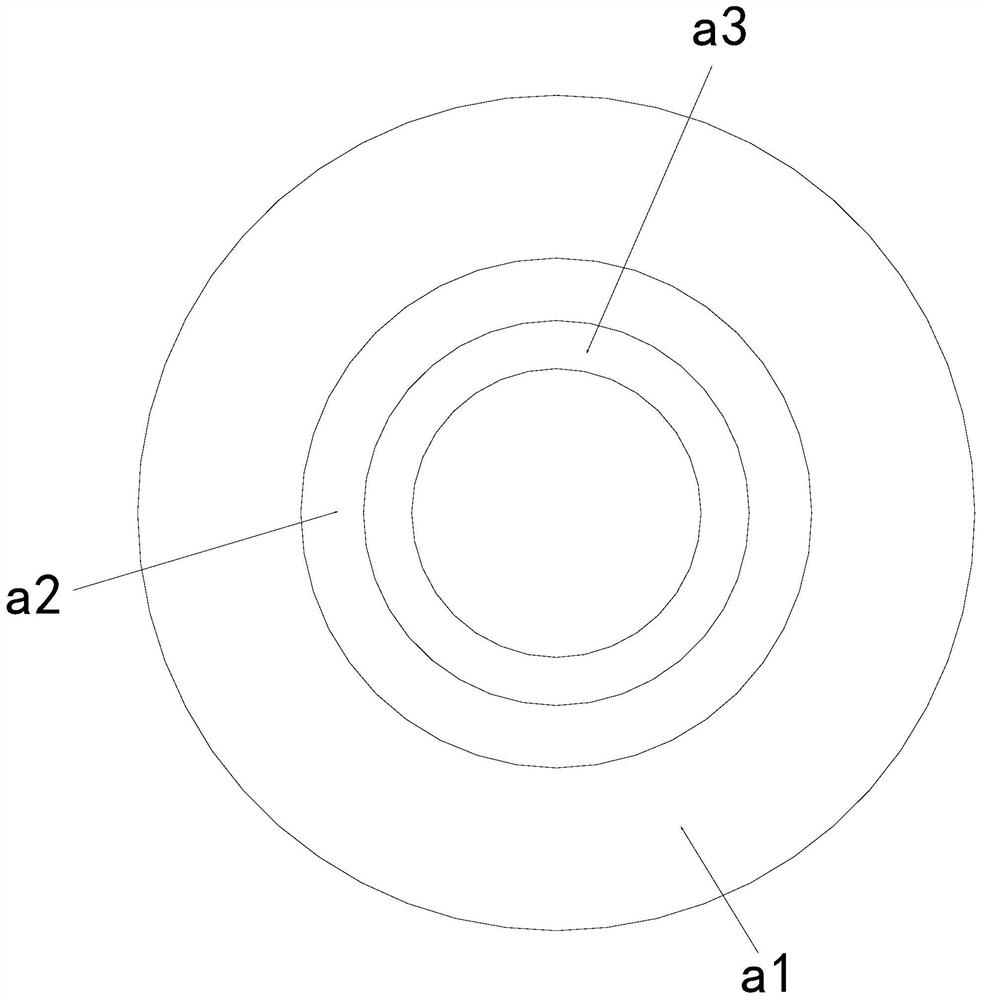

[0031] as attached Figure 5 to attach Figure 7 As shown: the booster b1 is composed of a fixed end plate c1, a connecting plate c2, a lifting plate c3, and a reactivator c4. The lower end of the fixed end plate c1 is welded and fixed to the inner wall of the outer ring b4, and the connecting plate The outer wall of the lower end of c2 is embedded and fixed on the upper end of the fixed end plate c1, the lower two ends of the lifting plate c3 are movably matched with the upper ends of the connecting card plate c2, the reactivator c4 is assembled on the inner wall of the connecting card plate c2, and the connecting card After the plate c2 is combined with the lifting plate c3, its structure is a ring structure, which can be averaged to the whole, so as to avoid the distortion of the structure caused by excessive force on a single point.

[0032]Wherein, the reactivator c4 is composed of the outer plate d1, the connecting bar d2, the nesting shaft d3, the clamping shaft d4, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com