Method for improving crystallization of grinding fluid of polishing head

A technology of polishing head and abrasive liquid, which is applied in grinding/polishing equipment, grinding/polishing safety devices, metal processing equipment, etc., and can solve problems such as crystallization of abrasive liquid

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

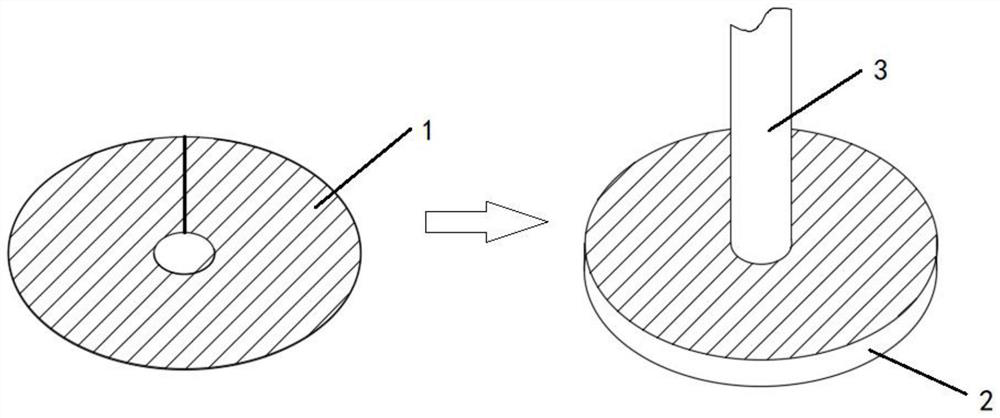

[0025] Specific embodiment 1, see figure 1 , a method for improving the crystallization of a polishing head abrasive liquid, comprising the steps of: Step 1, cutting a fine polishing abrasive cloth, using the fine polishing abrasive cloth as a polishing head protection pad 1; Step 2, wiping the surface of the polishing head 2 clean; Step 3, Adhere the cut polishing head protection pad 1 on the upper surface of the polishing head. This patent solves the problem of mechanical damage caused by the crystallization of the polishing head. It solves the difficulty of stopping and maintaining the polishing head and improves the productivity and work efficiency. After the improvement, the maintenance of the polishing head does not need to be shut down for one day per month for maintenance. It only needs to be replaced for about 6 months / time when the polishing head protection pad is damaged and stained during normal work. Easy maintenance. It takes 3-5 minutes to replace a polishing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com