Municipal garbage can capable of automatically distributing space

A technology of automatic distribution and garbage cans, applied in the field of garbage cans, can solve problems such as unreasonable use of municipal garbage can space, and achieve the effect of improving effective distribution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

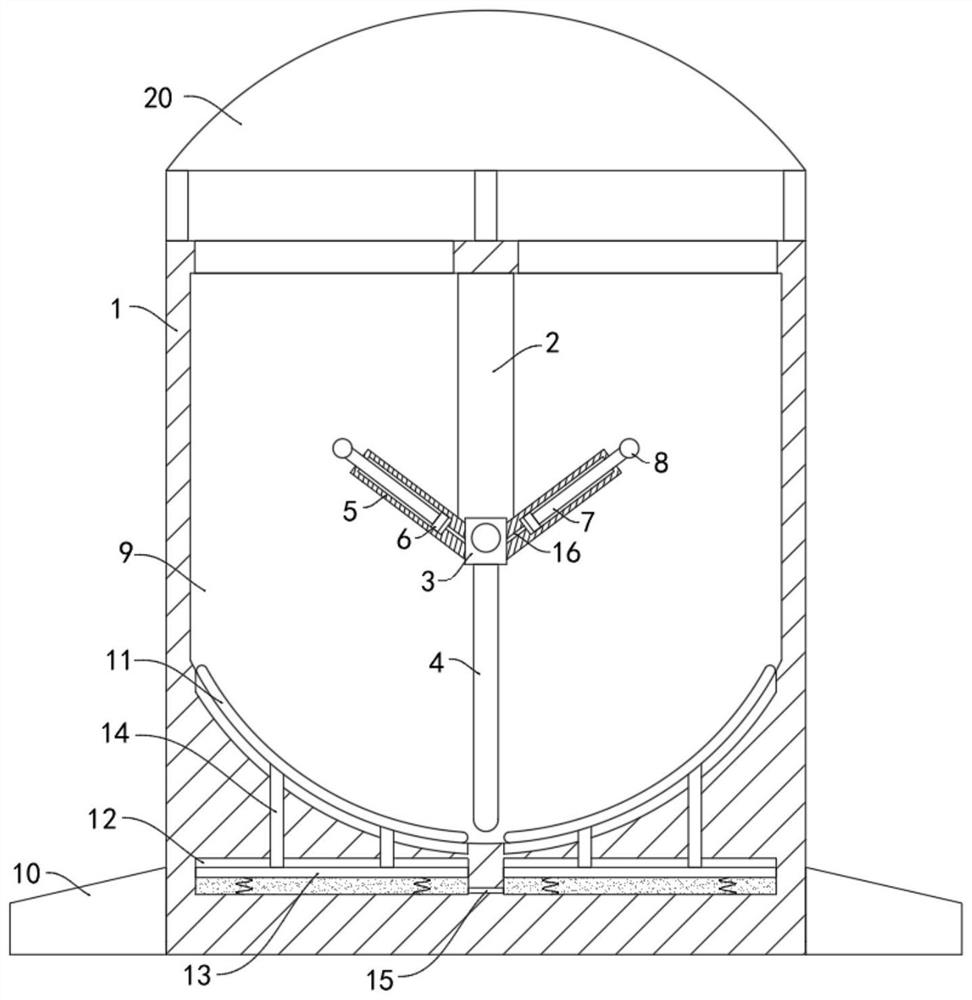

[0024] Such as Figure 1-2 As shown, a municipal trash can that can automatically allocate space includes a barrel body 1. It is worth mentioning that the upper end of the barrel body 1 is fixedly connected with a shield cap 20 through a plurality of vertical rods, which can reduce rainwater from entering the trash can, and The bottom of the outer wall of the barrel body 1 is fixedly connected with a plurality of fixing seats 10, and the increased bottom area can effectively increase the stability of the trash can.

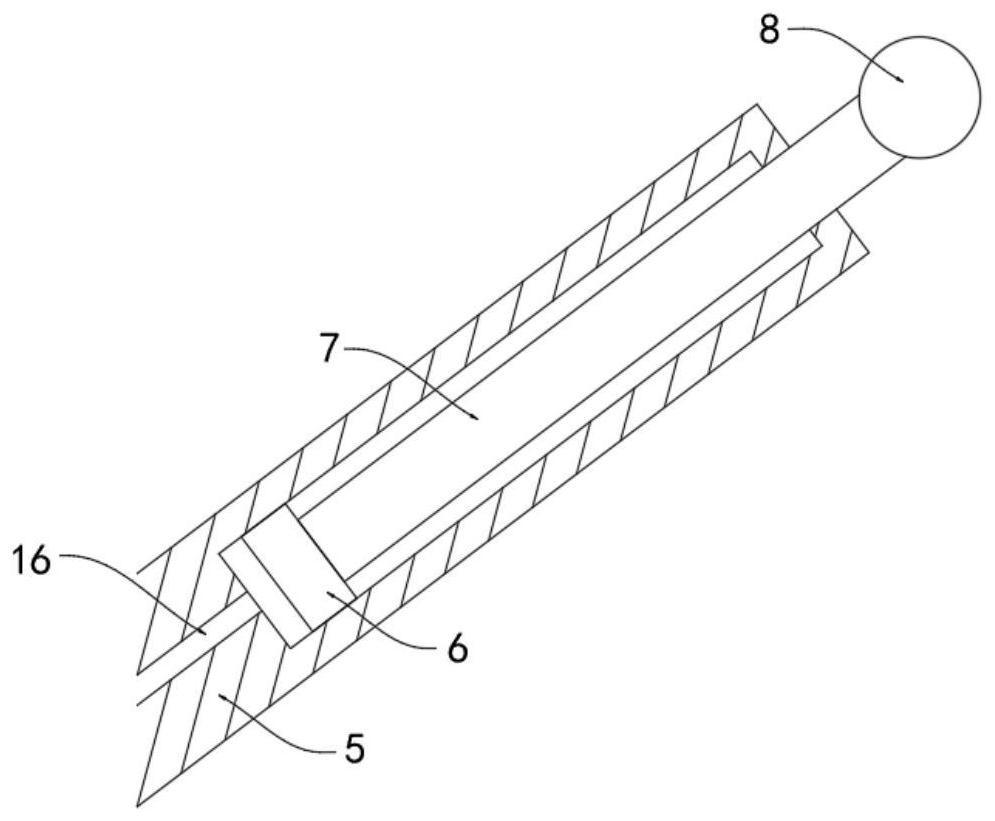

[0025] The inner bottom surface of the barrel body 1 is arranged in an inwardly concave arc shape, the barrel body 1 is fixedly connected with a vertical partition 2, the lower end of the partition plate 2 is rotatably connected with a rotating head 3, and the lower side wall of the rotating head 3 is fixedly connected with a distribution box. Plate 4, the sidewalls on both sides of the rotating head 3 are fixedly connected with fixed boxes 5, the ends of each fix...

Embodiment 2

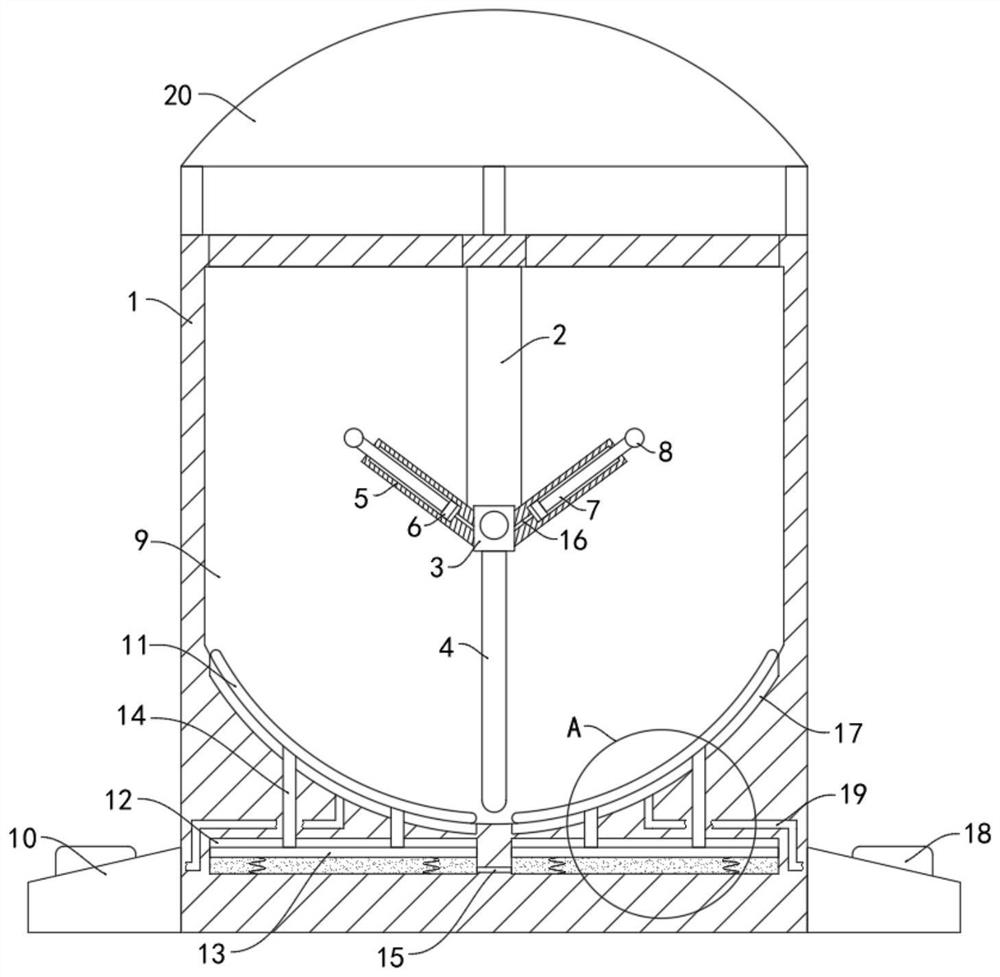

[0033] Such as Figure 3-4 As shown, the difference between this embodiment and Embodiment 1 is that: the inner bottom surface of the storage chamber 9 is provided with a groove 17 matched with the arc-shaped lifting plate 11, and the upper end of each fixing seat 10 is provided with an elastic tube installed inside. The foot button 18 communicates with the corresponding groove 17 through the pipeline 19 fixedly embedded in the barrel body 1 .

[0034] In this embodiment, when there is a lot of rubbish in the trash can, the foot button 18 at the corresponding end can be stepped on repeatedly, and the gas is intermittently injected into the groove 17 through the pipeline 19, and the gas will intermittently push the arc-shaped lifting plate 11 Moving up a certain distance can shake the garbage in the storage chamber 9 with more garbage, promote the garbage to move to the inside of the garbage can, and make full use of the inner space of the garbage can.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com