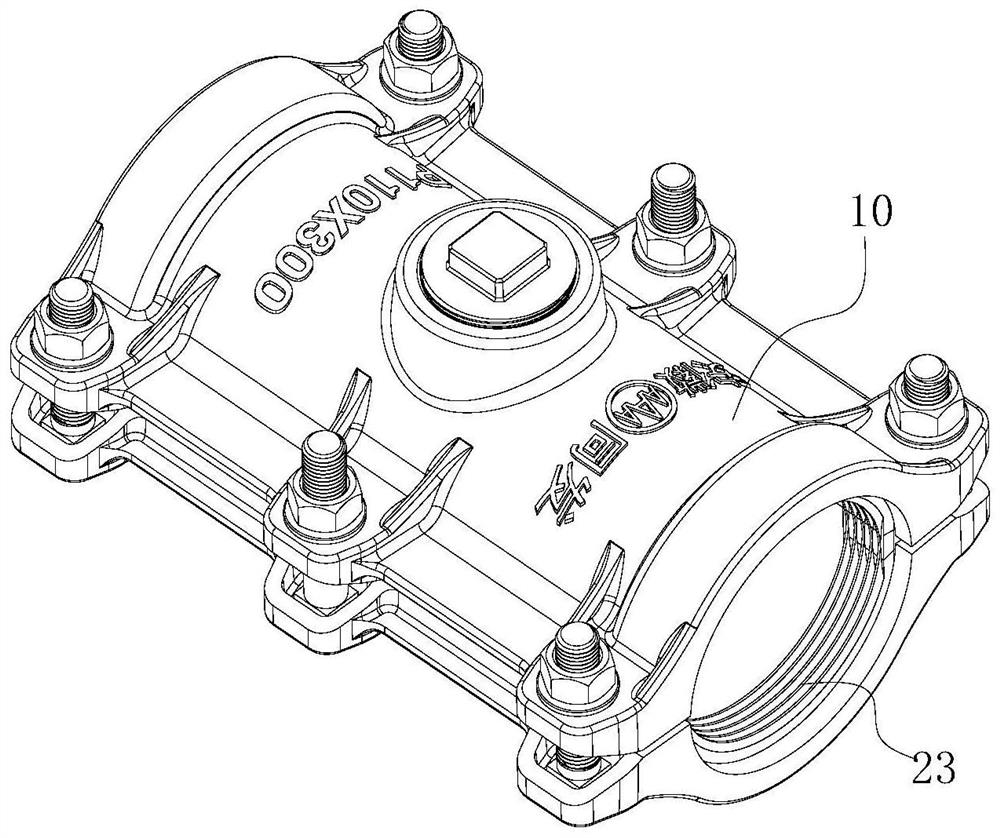

Half joint

A half-section, half-type technology, applied in the direction of pipes/pipe joints/fittings, mechanical equipment, pipe components, etc., can solve problems such as rubber ring displacement or misalignment, water seepage and leakage, and poor sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

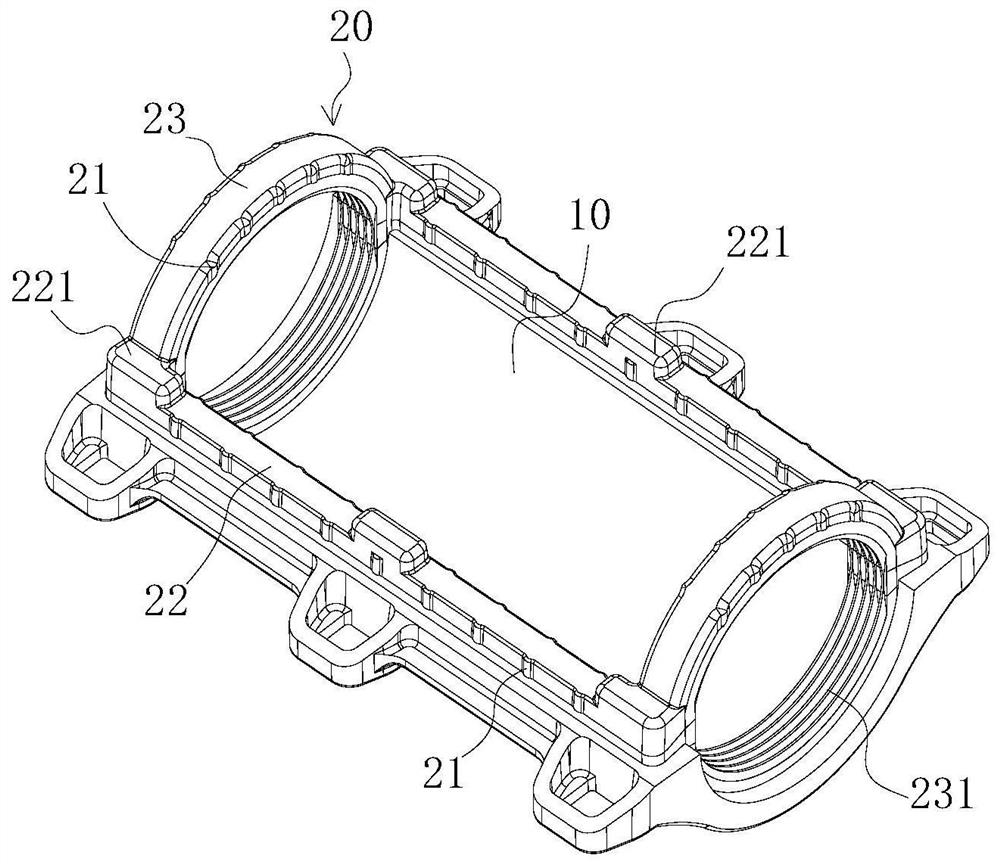

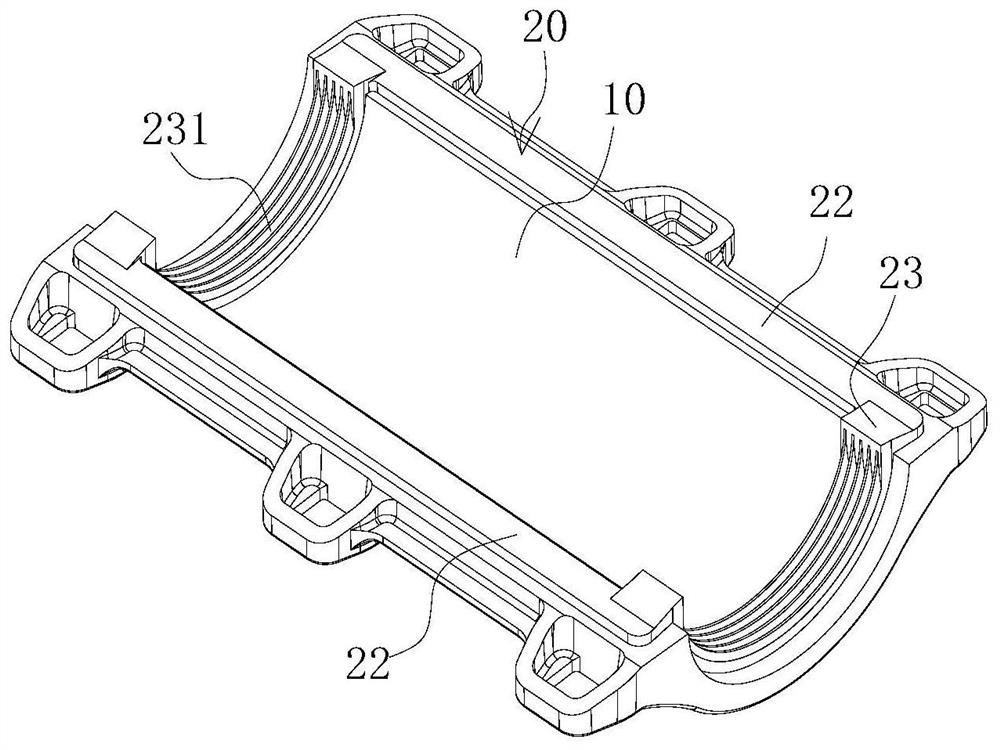

[0013] Embodiment one, such as figure 2 As shown, the ribs 21 are arranged on the part of the seal half 20 corresponding to the side wall of the groove. The sealing part half 20 is a rubber part, on which it is convenient to change the structure and arrange the ribs 21, and the original half-section mold can be retained without recasting, and the sealing part half 20 can be replaced directly.

Embodiment 2

[0014] Embodiment two, such as Figure 7 As shown, the ribs 21 are arranged on the inner wall of the straight groove 11 or the arc groove 12 . In this way, it can be directly cast and shaped, which is convenient for adapting to the existing half body 20 of the sealing element.

[0015] The rib length direction of the rib 21 points to the groove bottom of the straight groove 11 or the arc groove 12 . . This facilitates the installation of the extruded ribs 21 , and the extrusion force between the ribs 21 and the side walls of the groove is perpendicular to the bonding surface of the half joint, preventing the half body 20 of the sealing member from falling off.

[0016] The ribs 21 are arranged in a linear array along the length direction of the long straight section seal 22 , and the ribs 21 are arranged at even intervals along the circumference of the arc section seal 23 . In this way, ribs 21 are arranged everywhere on the half body of the sealing member 20 to prevent it ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com