Coffee powder scattering machine for making milk tea

A technology of milk tea and powder foam, which is applied in the field of powder spraying machines, can solve the problems of unfavorable cost saving, waste, laborious coffee powder, etc., and achieve the effect of uniform and delicate coffee powder

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

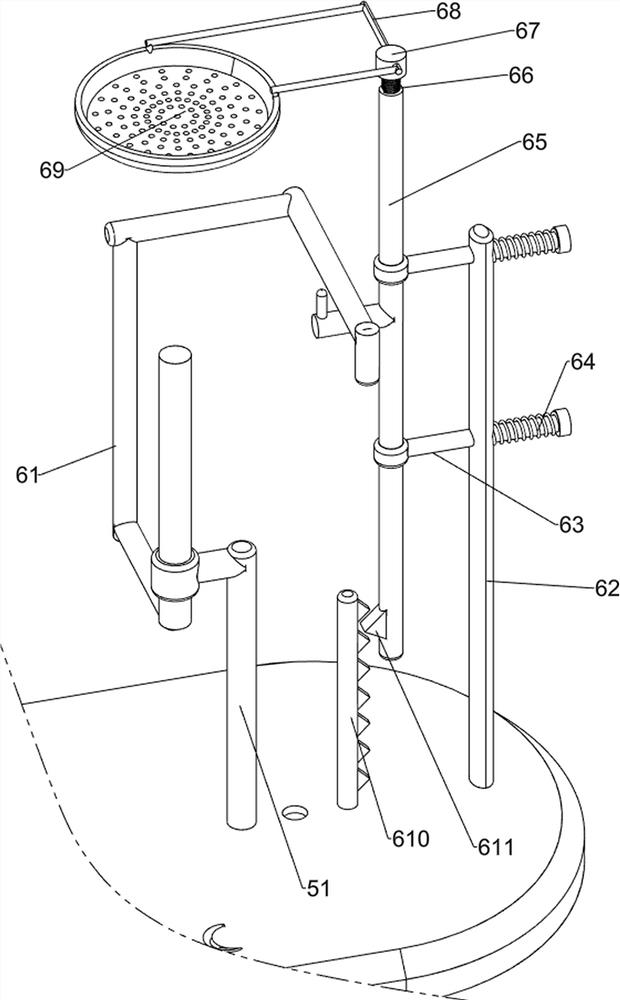

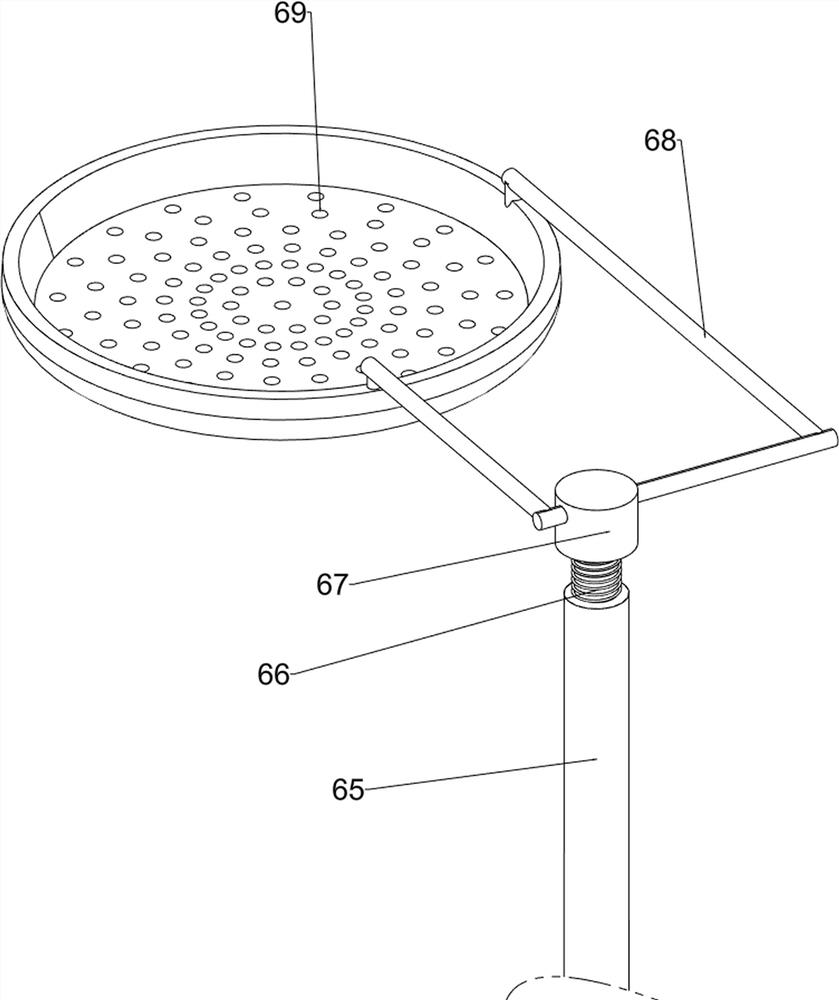

[0058] A kind of coffee powder sprinkler machine for making milk tea, such as figure 1 and Figure 4 As shown, it includes base plate 1, support column 2, tray 3, support frame 4, lifting mechanism 5 and screening mechanism 6, base plate 1 is provided with support column 2 on the right side, and support column 2 top is provided with tray 3, dragging The disc 3 is provided with a lifting mechanism 5, the lifting mechanism 5 is provided with a support frame 4, and the bottom plate 1 is provided with a screening mechanism 6 on the right side, and the screening mechanism 6 is located on the right side of the support column 2.

[0059] When in use, pour the coffee powder first, then turn the screening mechanism 6 clockwise, and put the milk tea into the support frame 4 at the same time, then let go of your hand, so that the screening mechanism 6 is rotated counterclockwise and resets. Due to the influence of the gravity of the milk tea, the screening mechanism 6 And the lifting me...

Embodiment 2

[0061] On the basis of Example 1, such as figure 2 , image 3 , Figure 4 and Figure 5 As shown, the lifting mechanism 5 includes a first sliding sleeve 51, a first connecting rod 52, a fixed sliding sleeve rod 53, a second spring 54 and a lifting and placing plate 55. The right side of the base plate 1 is provided with the first sliding sleeve 51, and the second A sliding sleeve 51 is positioned at the left side of the support column 2, the screening mechanism 6 is provided with a first connecting rod 52, and the top of the tray 3 is uniformly provided with a fixed sliding sleeve rod 53, and the top of the fixed sliding sleeve rod 53 is connected with the support frame 4, and the fixed sliding sleeve rod 53 is connected Sliding between the upper parts of the sleeve rods 53 is provided with a lifting and placing plate 55, and the fixed sliding sleeve rods 53 at intervals are provided with a second spring 54. connect.

[0062] After the milk tea is put into the support fram...

Embodiment 3

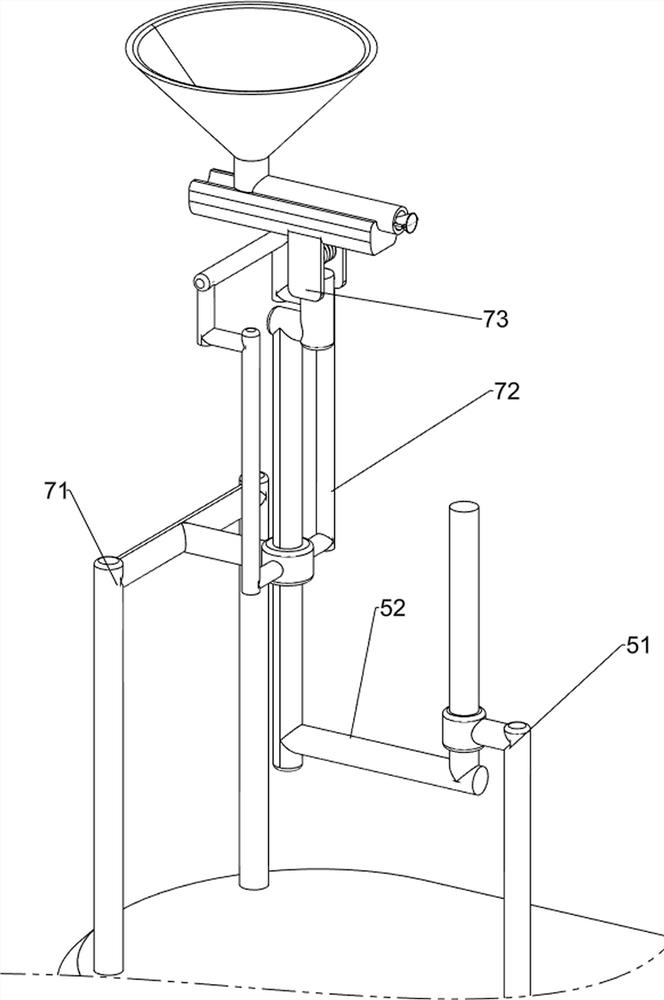

[0066] On the basis of Example 2, such as figure 1 , Figure 4 , Figure 5 , Figure 6 and Figure 7 As shown, it also includes a blanking mechanism 7 and a booster mechanism 8, the upper left side of the base plate 1 is provided with a blanking mechanism 7, and the upper front side of the base plate 1 is provided with a booster mechanism 8.

[0067] When in use, first pour the coffee powder into the feeding mechanism 7, the first connecting rod 52 moves downward to drive the feeding mechanism 7 to move down and pour the coffee powder into the sieve 69, after use, the first connecting rod 52 moves upward The movement drives the unloading mechanism 7 to move upwards and reset. If the weight of the milk tea is not enough to drive the lifting and placing tray 55 to move downward, the booster mechanism 8 can be pressed down to drive the lifting and placing tray 55 to move downward. The booster mechanism 8 will move upwards and reset, and repeat the above-mentioned operations w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com