A dust removal and cleaning device for a mask processing workshop

A technology for processing workshops and cleaning devices, which is applied in the direction of removing smoke and dust, cleaning hollow objects, cleaning methods and utensils, etc. It can solve the problems of easy danger, reduced dust removal effect, and poor cleaning of dust removal channels to achieve the effect of avoiding danger

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

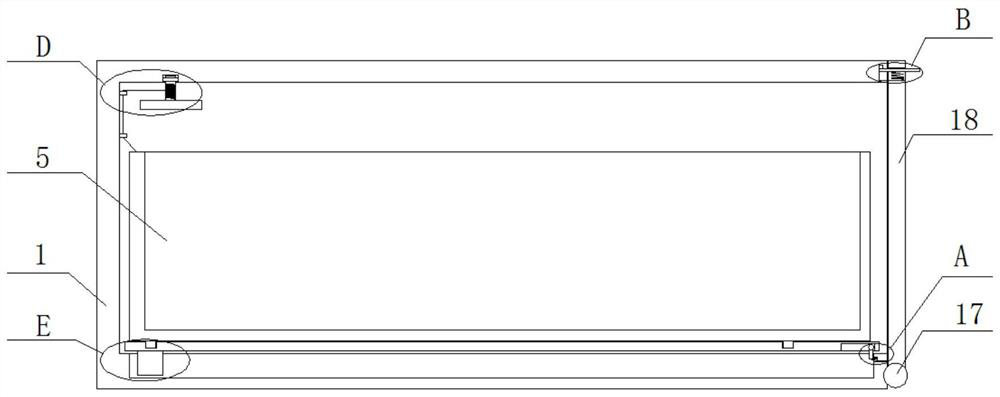

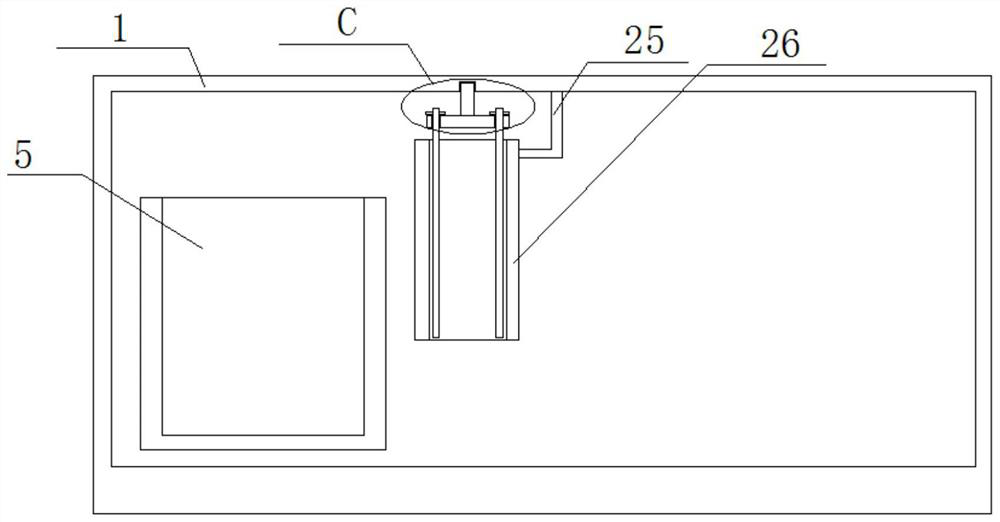

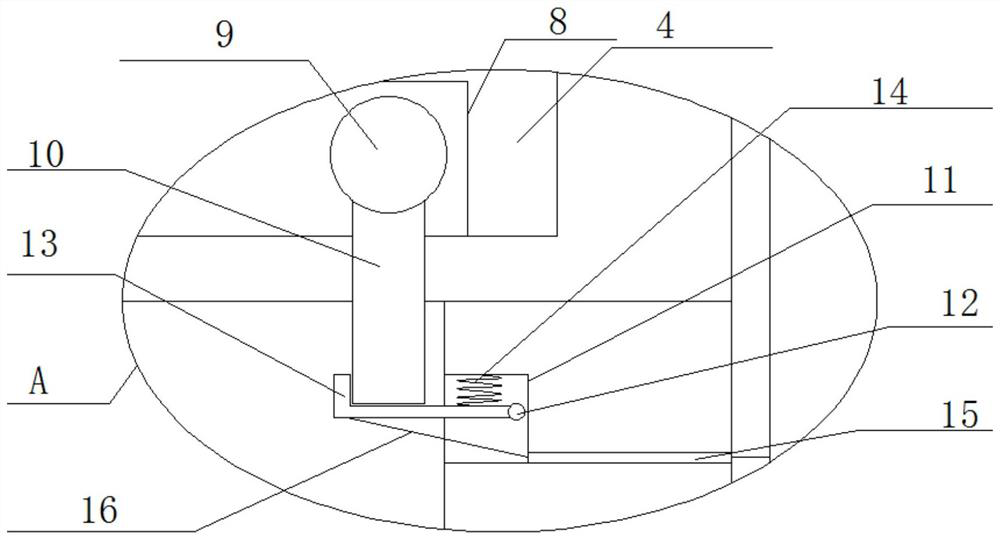

[0029] refer to Figure 1-8 , a dust removal and cleaning device for a mask processing workshop, comprising a dust chamber 1, one side of the dust chamber 1 is an opening structure, a sliding groove 2 is opened on the inner wall of the bottom of the dust chamber 1, and a sliding block is slidably installed in the sliding groove 2 3. A sliding plate 4 is fixedly installed on the top of the sliding block 3. The sliding plate 4 is adapted to the dust chamber 1. There are fixing grooves 6 on both sides of the top of the sliding plate 4, and a dust collecting box is fixed on the sliding plate 4. 5. A fixing block 7 is fixedly installed on both sides of the bottom of the dust collecting box 5, and the fixing block 7 is adapted to the fixing groove 6. A first groove 8 is opened on the side of the bottom of the sliding plate 4 near the opening. The side of the groove 8 close to the opening is rotatably installed with a first rotating shaft 9, a rotating rod 10 is fixedly installed on ...

Embodiment 2

[0031] In the present invention, a third rotating shaft 17 is rotatably installed on the bottom of the cleaning chamber 1 near the opening, and a baffle 18 is fixedly installed on the third rotating shaft 17 , and the baffle 18 is adapted to the cleaning chamber 1 .

[0032] In the present invention, a wire hole 15 is provided on the inner wall of the bottom of one side of the second groove 11, one end of the rubber rope 16 is fixedly installed on the bottom side of the stop lever 13, and the other end of the rubber rope 16 passes through the wire hole 15 and the baffle plate. 18 is fixedly connected to the side close to the dust chamber 1, and the rubber cord 16 is used for connection and reset.

[0033] In the present invention, a first through hole 19 is formed on the top of one side of the baffle plate 18 , a third groove 20 is formed on the top of one side of the vacuum chamber 1 near the opening, and the inner wall of the top of the third groove 20 is formed on one side. ...

Embodiment 3

[0039] A dust removal and cleaning device for a mask processing workshop, comprising a vacuum chamber 1, one side of the vacuum chamber 1 is an open structure, a sliding groove 2 is chiseled on the inner wall of the bottom of the vacuum chamber 1, and a sliding block 3 is slidably installed in the sliding groove 2 , the top of the sliding block 3 is fixedly welded with a sliding plate 4, the sliding plate 4 is adapted to the dust chamber 1, the top of the sliding plate 4 is chiseled with fixing grooves 6 on both sides, and a dust collecting box 5 is fixed on the sliding plate 4. , both sides of the bottom of the dust collecting box 5 are fixedly welded with a fixing block 7, and the fixing block 7 is adapted to the fixing groove 6, and the side of the bottom of the sliding plate 4 close to the opening is chiseled with a first groove 8. A first rotating shaft 9 is rotatably installed on the side of the groove 8 close to the opening, a rotating rod 10 is fixedly welded on the fir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com