A seamless splicing correction method and device for an LED display

An LED display, seamless splicing technology, applied in static indicators, instruments, etc., can solve problems such as poor calibration effect on large screens, detection of missing, limited pixels on graphics cards, and achieve uniform brightness and eliminate brightness measurement errors. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0065] DETAILED DESCRIPTION OF THE PREFERRED EMBODIMENTS It should be understood that the specific embodiments described herein are intended to illustrate and explain the disclosure and is not intended to limit the disclosure.

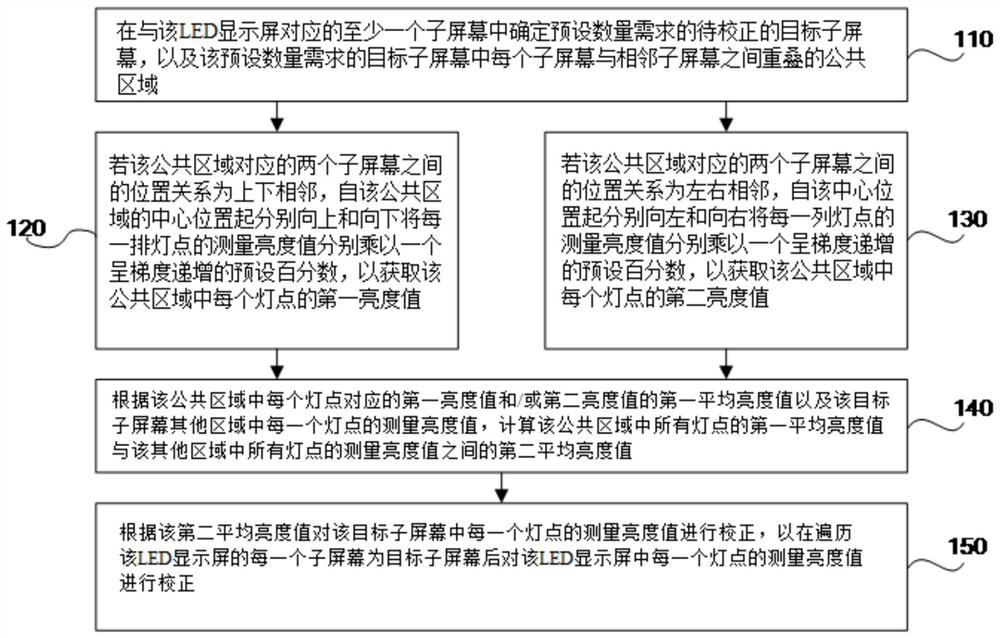

[0066] figure 1 It is a flow chart of a seamless splicing correction method of an LED display according to an exemplary embodiment, such as figure 1 As shown, it is applied to the server, which includes:

[0067] The target application scenario according to various embodiments in the present disclosure is first introduced, and the target application scenario includes a server, which is a computing function and can respond And send a service request server. The server can be, for example, a server in a control terminal.

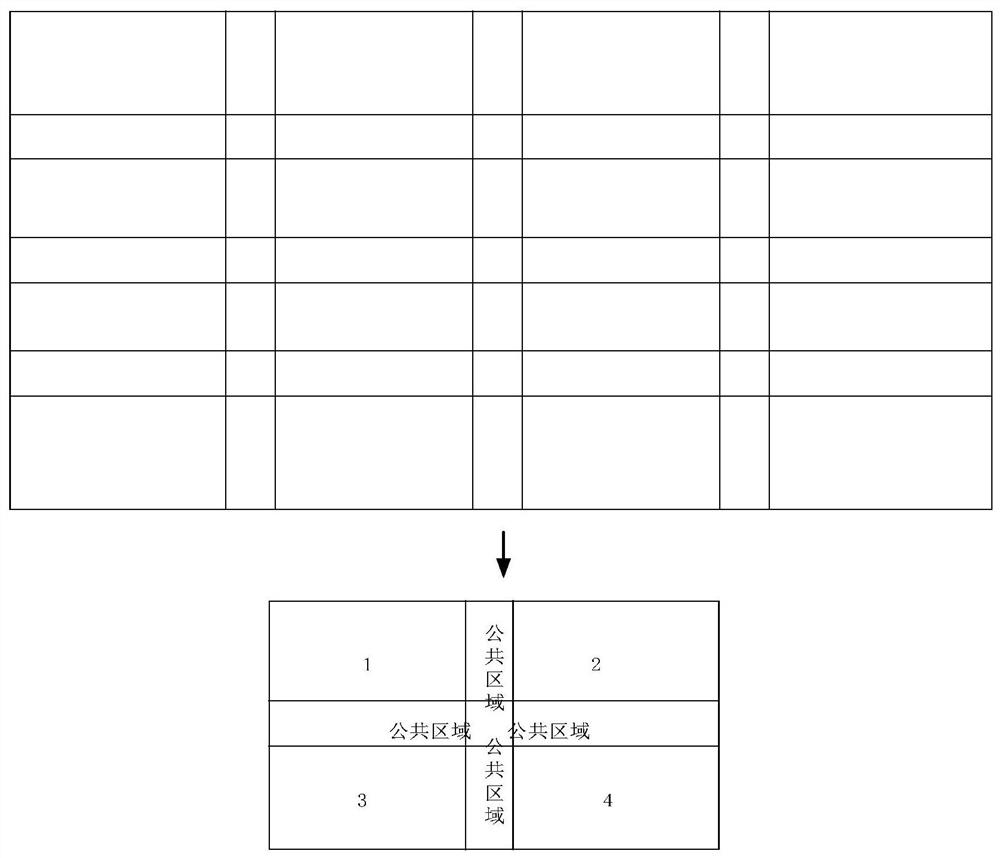

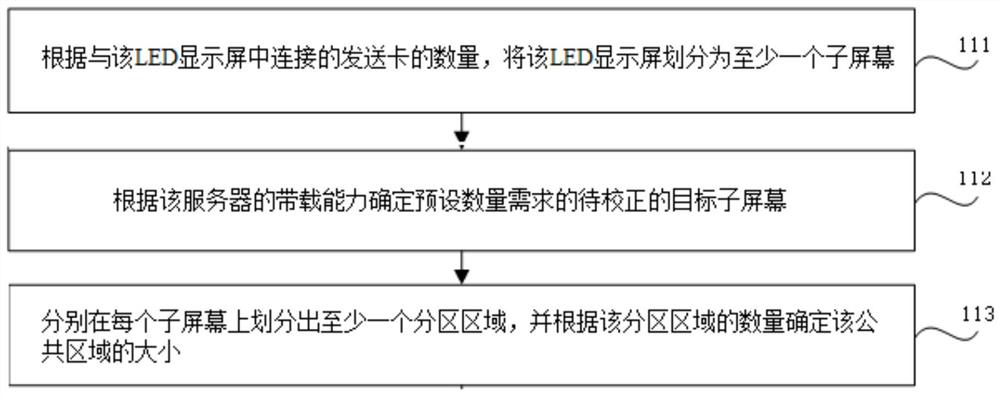

[0068] In step 110, the target sub-screen to be corrected in the preset quantity requirement is determined in at least one sub-screen corresponding to the LED display, and each sub-screen and the adjacent sub-screen in the target sub-scre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com