Trackless precise measurement method for catenary suspension point position in subway tunnel

A catenary and hanging point technology, applied in geometric CAD, word processing, overhead lines, etc., can solve problems such as restricting the construction progress of catenary, and achieve the effects of improving measurement efficiency and accuracy, improving economic benefits, and reducing impact.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention includes the following steps.

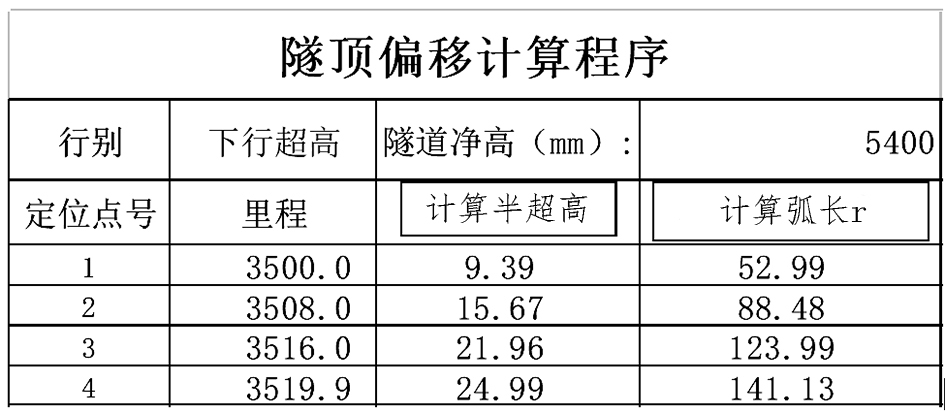

[0033] Firstly, the technical data is compiled, and the mileage of each positioning point is calculated according to the catenary layout diagram, and the relationship between the line mileage and coordinates is obtained according to the line information provided by the design institute (such as curve elements, broken links, and fork positions, etc.). The relationship between mileage and coordinates is back calculated to obtain the coordinate data of each positioning point, and the results are summarized to form a measurement technical data table.

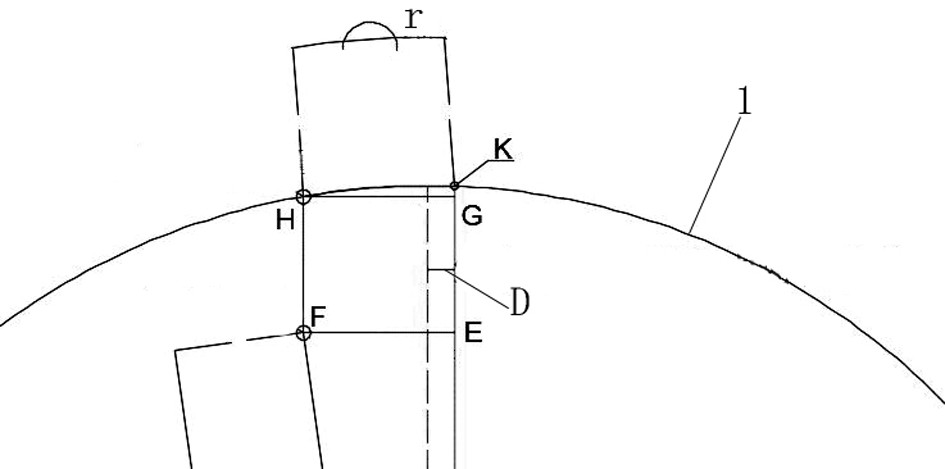

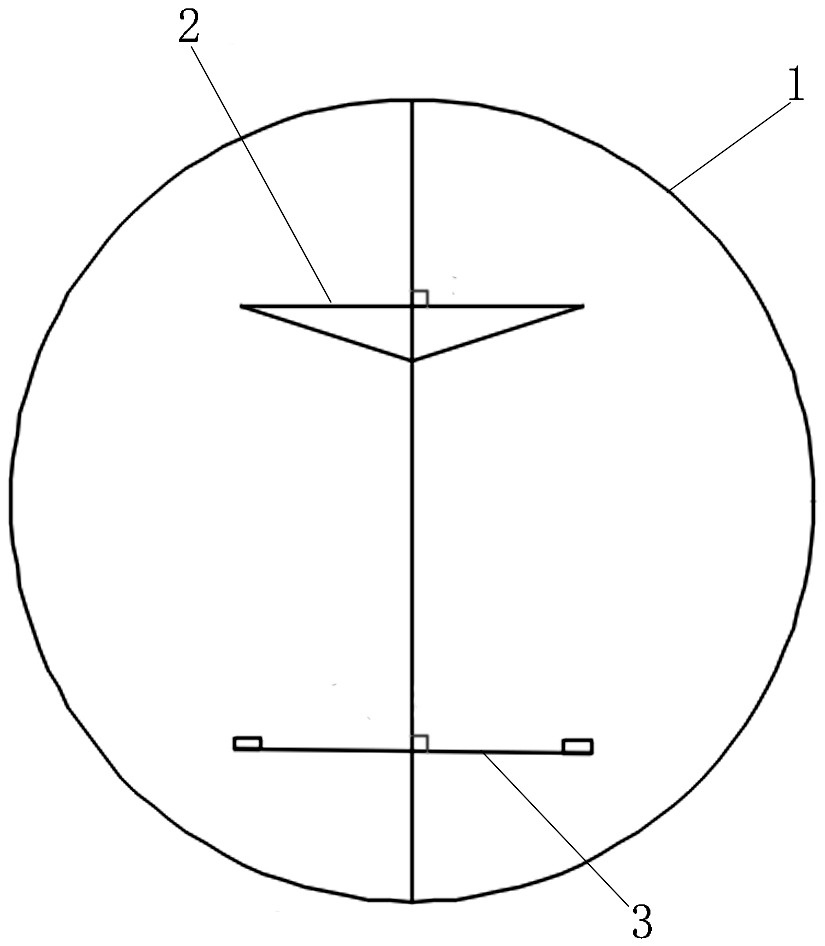

[0034] Then measure and mark the center of the line on the ground of tunnel 1. The operator of the total station observes the prism in real time according to the coordinates X and Y of the positioning point in the measurement table, and guides the operator to move to the precise position, and the assistant makes a mark at this position (the center mark M of the ground line...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com