Reversely-threading wire distribution construction process for office network

A construction technology and wiring technology, which is applied in the field of cable construction schemes in integrated wiring, can solve problems such as increasing construction difficulty, increasing workload, and destroying floor steel bars, so as to reduce workload and construction costs and meet indoor elevation requirements. The effect of reducing the influence of cross construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

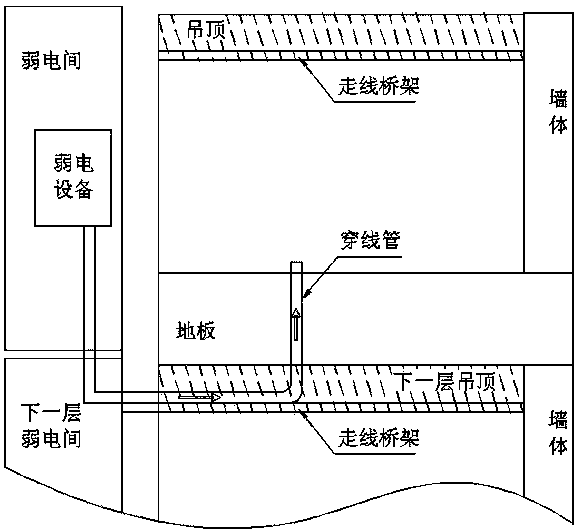

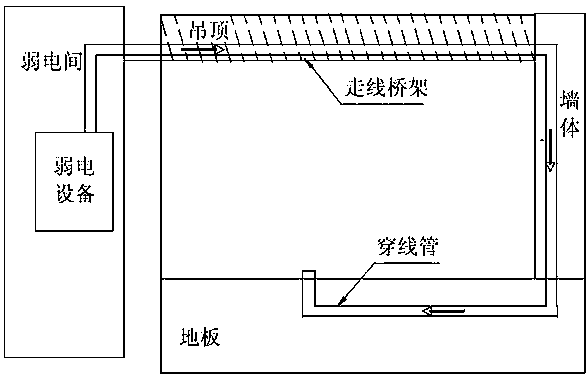

[0032] Such as figure 1 and figure 2 Shown, a kind of reverse penetration wiring construction technology of office network of the present invention, it comprises the following steps:

[0033] 1) Determine the wiring path and the location of the threading hole according to the design and placement of the furniture in the partitioned office area.

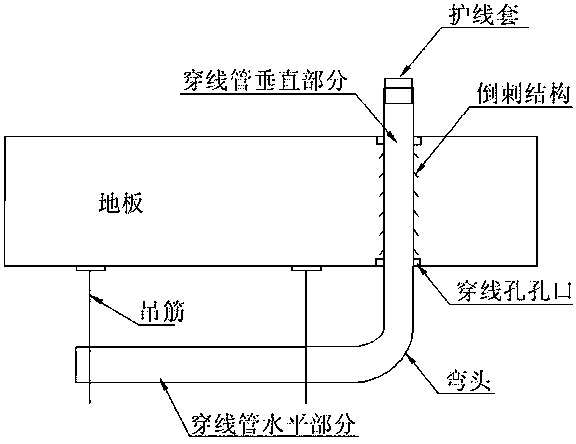

[0034] 2) Make the threading pipe, the manufacturing method of the threading pipe is: bend the threading pipe at 600mm, bend it into an arc of 90 degrees, and then make an evenly distributed anti-slip structure on the outer wall of the vertical part; the anti-slip structure adopts Barbed structure with the head pointing down.

[0035] 3) Drill holes on the floor, and the threading holes vertically penetrate the floor and have a diameter slightly larger than that of the threading pipe.

[0036] 4) Pass the threading pipe upwards from the threading hole under the floor, and the upper end of the threading pipe is higher than the gro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com