An abnormal vibration diagnosis method and system for an intelligent spindle

A technology of abnormal diagnosis and spindle, which is applied in the testing of mechanical components, testing of machine/structural components, instruments, etc., can solve the problems of inconvenient implementation, and achieve the effect of simple structure and easy implementation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] The present invention provides a vibration abnormality diagnosis system of an intelligent spindle. The main improvement of the system lies in the vibration data collection of the spindle in the radial plane. Therefore, the following content mainly focuses on the vibration data collection part of the system.

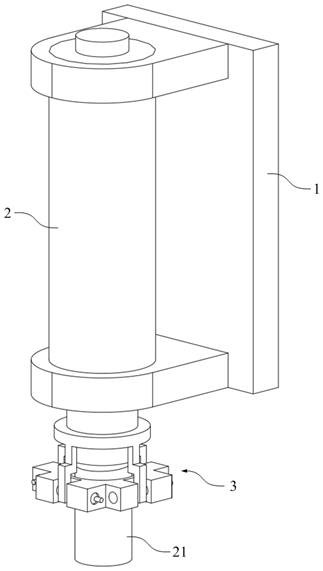

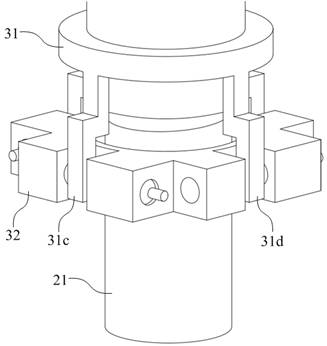

[0046] refer to Figure 1-4 , in the embodiment of the present invention, the system includes a vibration monitoring device 3 , the vibration monitoring device 3 is set on the output shaft 21 of the main shaft unit 2 , and the main shaft unit 2 is set on the frame 1 .

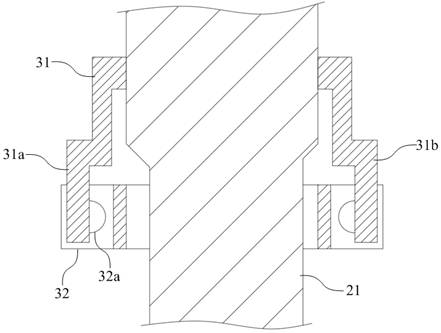

[0047] The vibration monitoring device 3 includes a vibration pickup ring 31 and a fixed ring 32 , both of which are sleeved on the output shaft 21 of the spindle unit 2 . Wherein, the vibration pickup ring 31 can vibrate with the vibration of the output shaft 21 ; and the fixed ring 32 is fixed on the frame 1 through a fixing member (not shown in the figure), so as to be fixed relative to the outpu...

Embodiment 2

[0070] refer to Figure 6-7 , on the basis of the above-mentioned embodiment 1, a plurality of elastic arms 33 are arranged between the vibration pickup ring 31 and the fixed ring 32, specifically, the elastic arms 33 are made of silica gel. The vibration pickup ring 31 is elastically connected to the fixing ring 32 through the elastic arm 33 . The elastic arm 33 can weaken the torsion force exerted by the output shaft 21 on the pickup ring 31 , further preventing the pickup ring 31 from rotating due to the rotation of the output shaft 21 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com