A micro-feeding device for uniform removal of material at the tip of a circular arc-edged diamond tool

A diamond tool and micro-feed technology, which is used in grinding drive devices, manufacturing tools, metal processing equipment, etc., can solve the problem of not being able to achieve uniform removal of diamond tool tip arc materials, and improve waviness and quality. High and increased grinding pressure effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

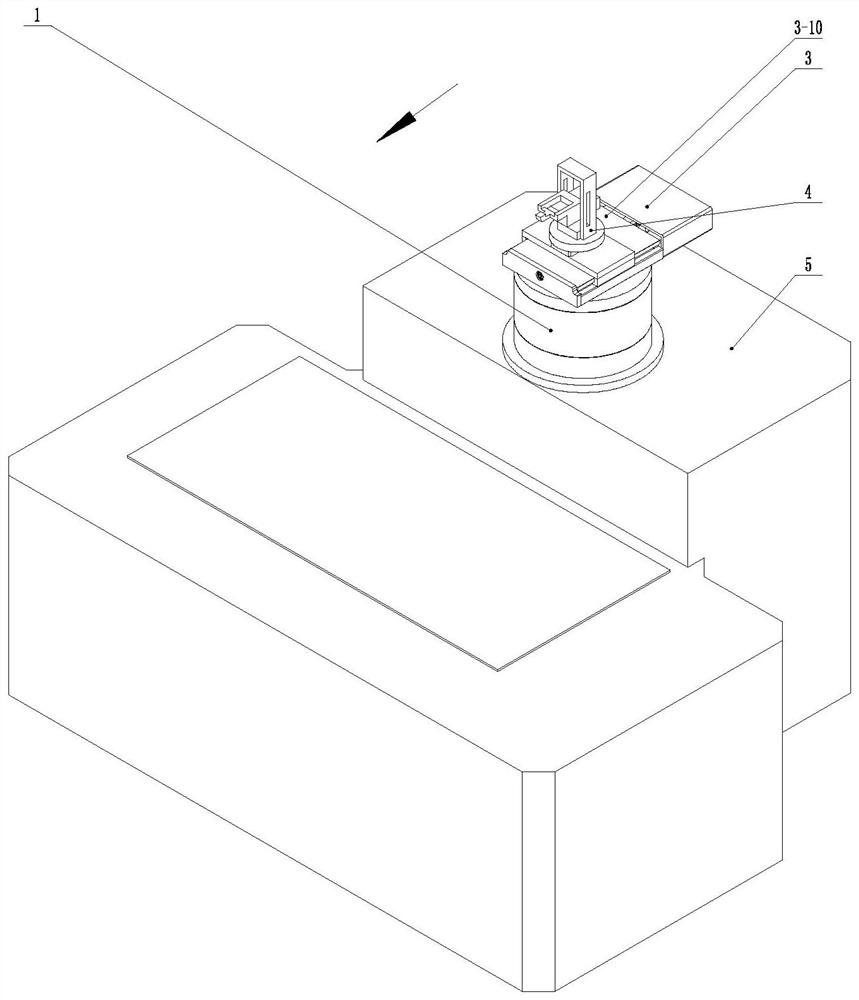

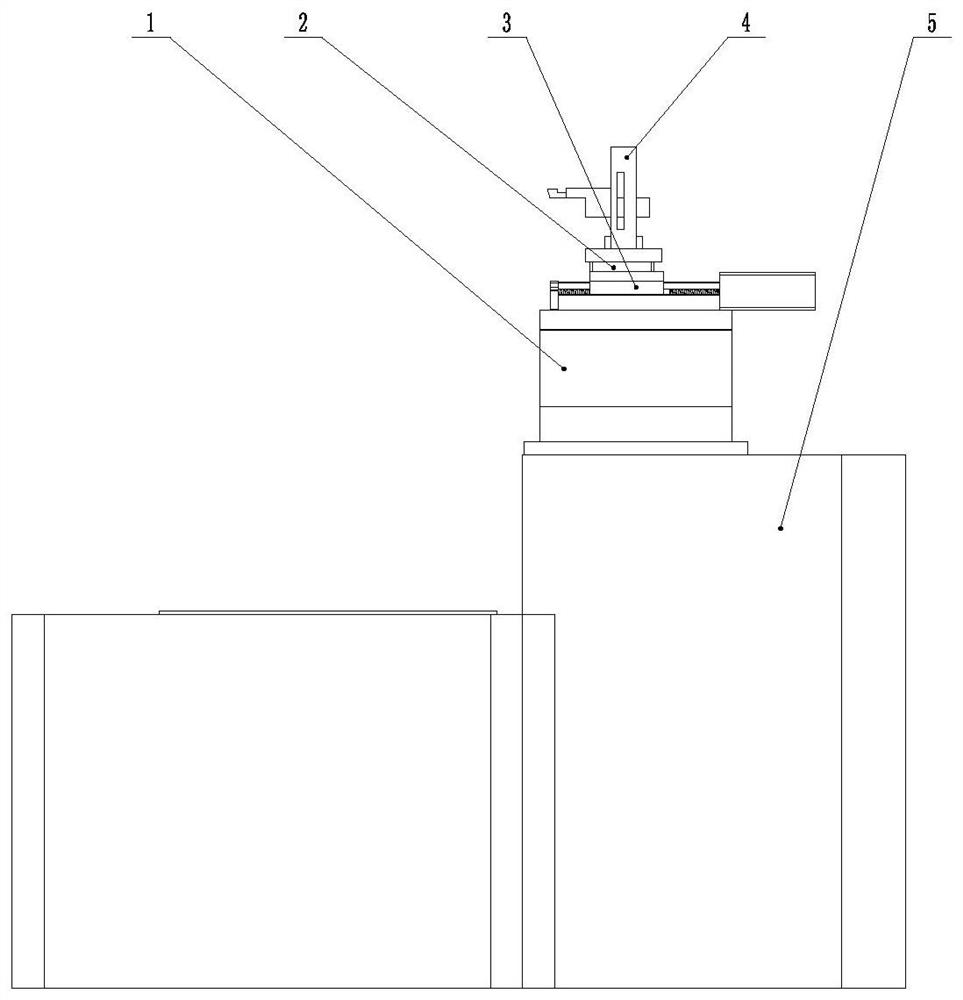

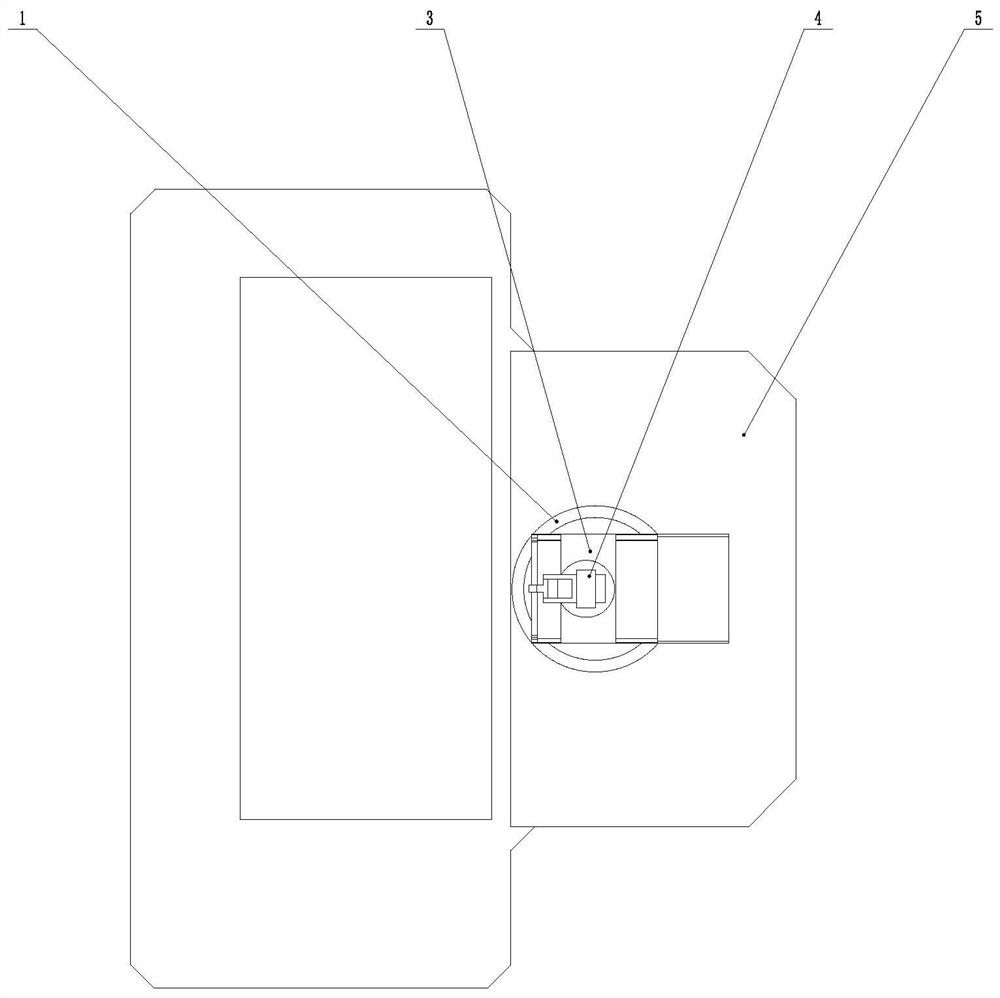

[0022] Such as Figure 1~Figure 6 As shown, a micro-feeding device for evenly removing the tip material of a circular arc edge diamond tool includes a hydrostatic turntable component 1, a micro-feeding component 2, a rough-feeding component 3, a tool rest 4 and a machine tool base 5; The tool holder 4 is installed on the micro-feeding part 2, and the micro-feeding part 2 is arranged on the rough-feeding part 3, and the rough-feeding part 3 is installed on the hydrostatic turntable part 1, and the hydrostatic The press turntable part 1 is fixed on the upper surface of the machine tool base 5 .

[0023] Such as Figure 5 As shown, the micro-feeding part 2 includes a flexible hinge 2-1, a piezoelectric ceramic 2-2 and a rigid support frame 2-3; the flexible hinge 2-1 and the rigid support frame 2-3 are an integral structure, The left side of the piezoelectric ceramic 2-2 is fixedly connected to the right side of the flexible hinge 2-1, and the right side of the piezoelectric ce...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com