A method for uniform removal of material at the tip of a circular arc-edged diamond tool

A diamond tool, arc edge technology, applied in the direction of manufacturing tools, metal processing equipment, grinding machine parts, etc., to achieve the effect of improving the quality of the tool tip arc and simple, convenient and uniform removal operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

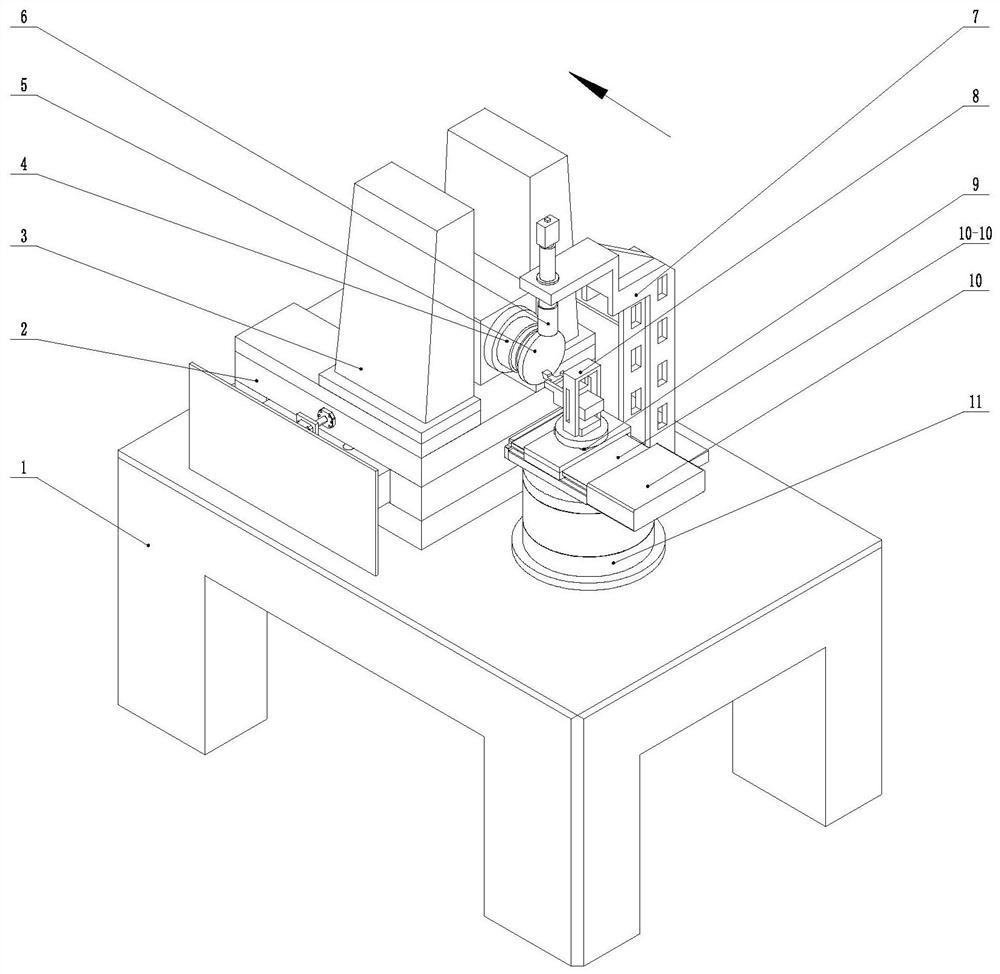

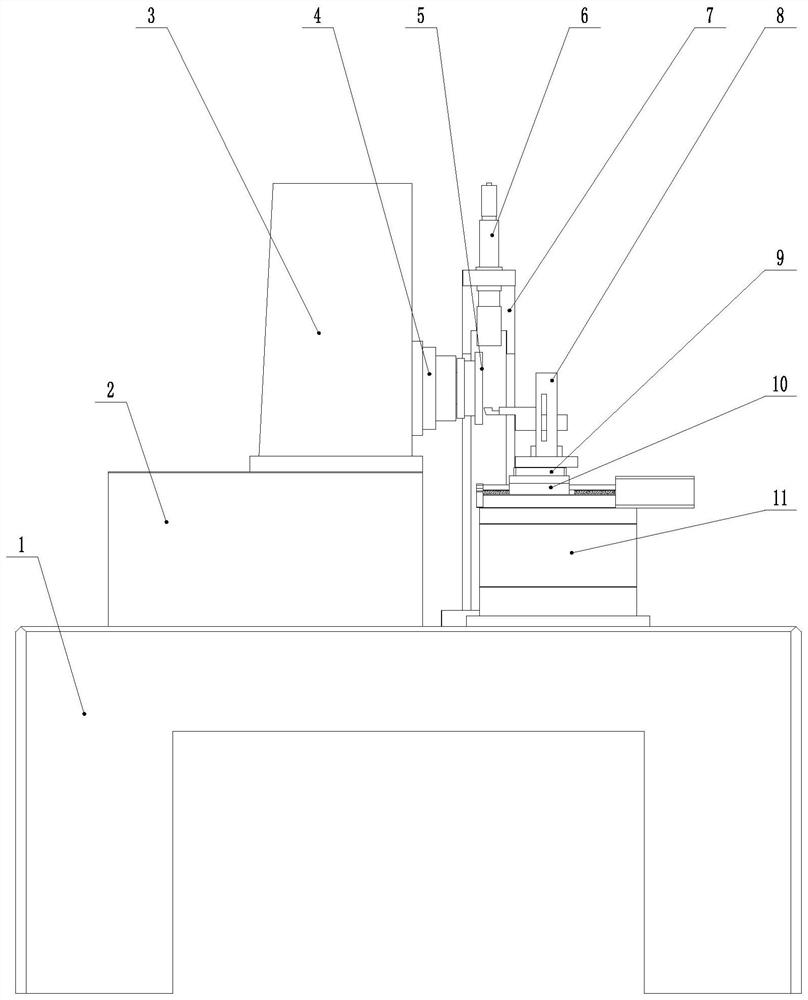

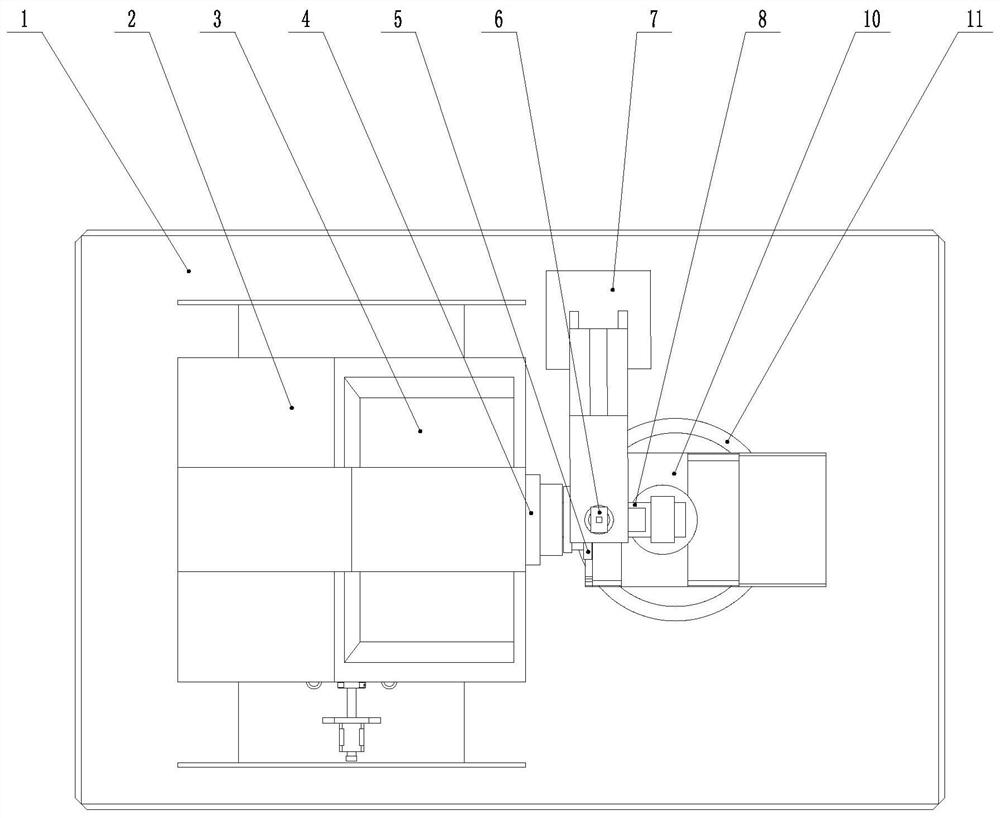

[0028] Attached below Figure 1-6 The present invention is described in detail.

[0029] A method for uniformly removing material at the tip of a circular arc edge diamond tool, comprising the following steps:

[0030] S1. Establish the grinding device of the arc edge diamond tool tip; the radial stiffness and axial stiffness of the main shaft part 4 of the grinding device are 220N / μm and 180N / μm respectively, the grain size of the grinding wheel grinding disc 5 is #3000, and the feed motion Select the combination of rough feed and micro feed, which is realized by the rough feed part 10 and the micro feed part 9 respectively;

[0031] S2. the knife is welded to the handle of a knife, (the knife is a diamond blade blank cut by a laser) and the handle of a knife is installed horizontally on the knife rest 8 of the grinding device;

[0032] S3. Adjust the pitch angle of the main shaft part 4 of the grinding device to be consistent with the back angle of the tool to be ground, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com