Method and device for shaping an inductance coil

A technology of winding components and equipment, applied in the direction of electrical components, electric components, electromechanical devices, etc., can solve the problems of difficult manufacturing and high cost of winding components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

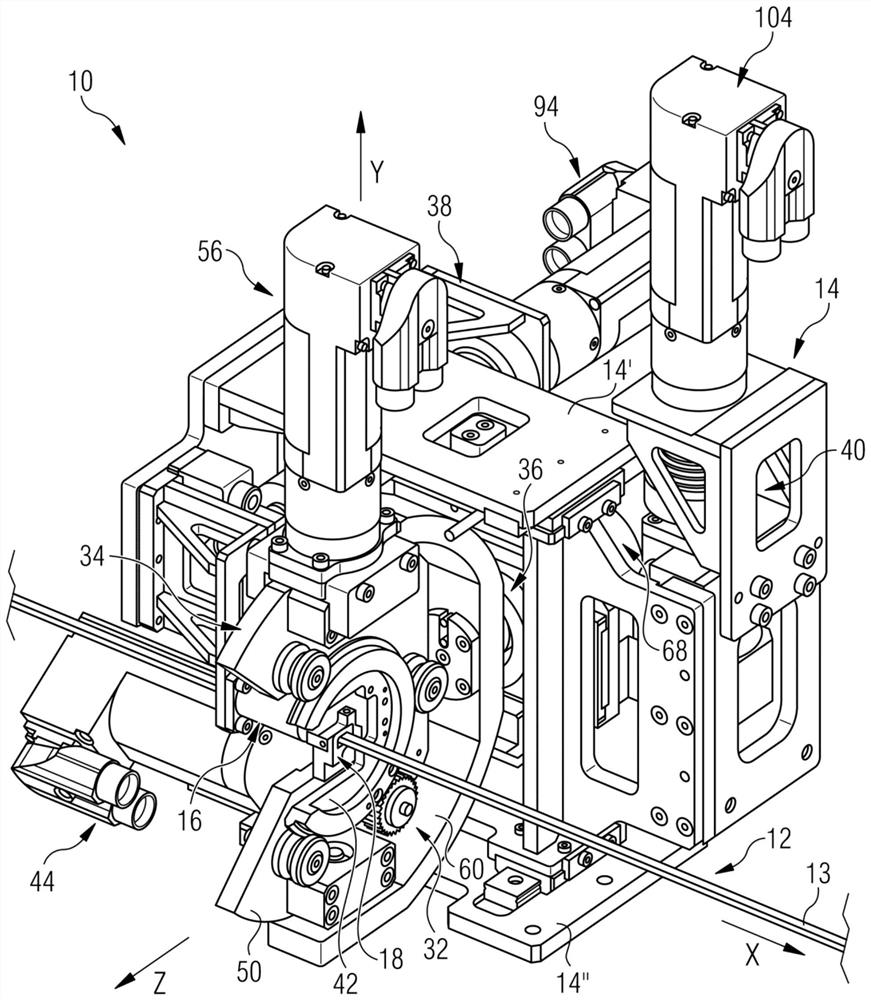

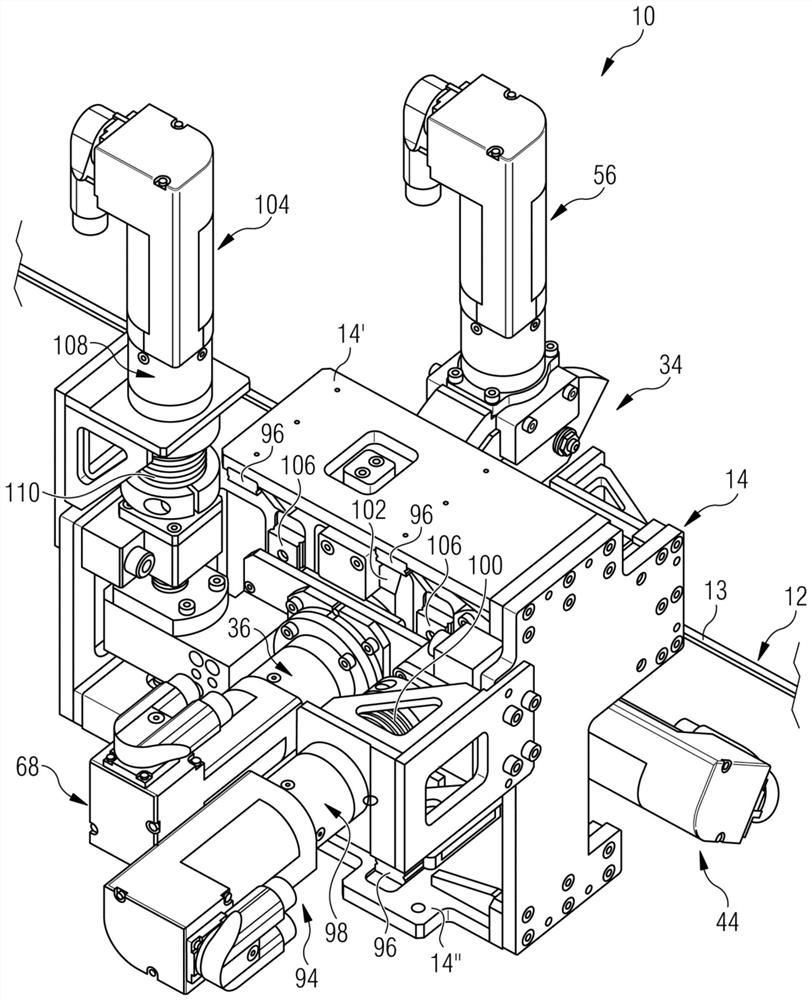

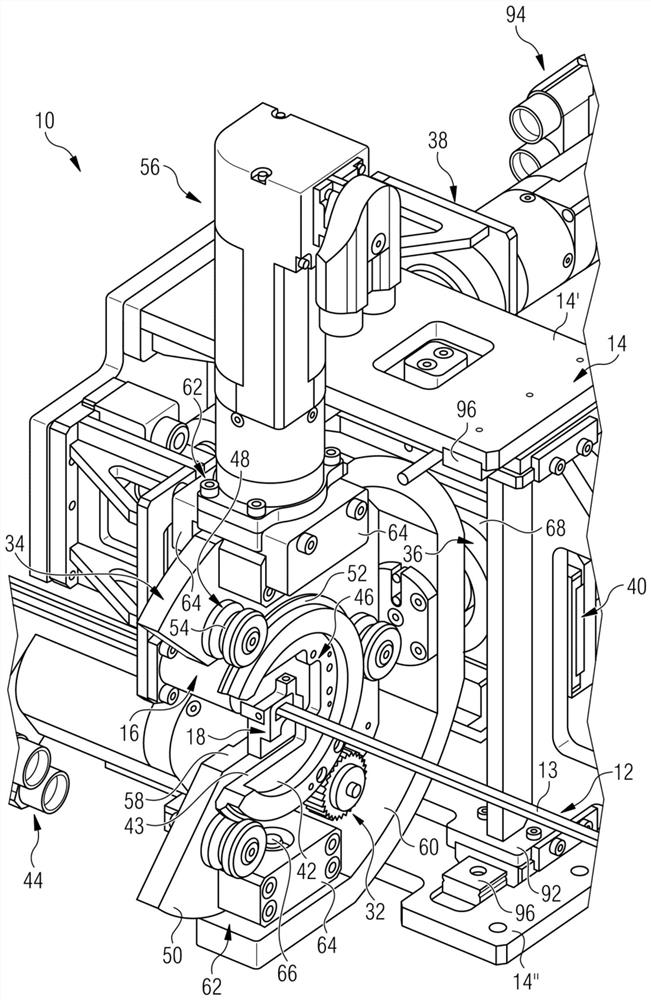

[0055] figure 1A device 10 is shown for forming, for example, a hair-fork-shaped winding element (“hairpin”) from a conductor 12 . The conductor 12 extends elongately in the longitudinal direction (X direction) and has an outer side 13 extending in the longitudinal direction. The components of the apparatus 10 are coupled or fastened to a frame 14 which serves as a support structure.

[0056] Device 10 includes ( figure 1 Partially hidden in the center) guide 16 and retrofit device 18 through which the conductor 12 is guided. The reforming device 18 is movable relative to the guide 16 by means of pivoting devices and compensating devices, so that the conductor 12 guided by the guide 16 and the reforming device 18 can be reformed, for example, into a fork-shaped winding element. This is explained in detail below, where, with reference to figure 1 The spatial axes (X, Y, and Z) drawn in . The X-axis extends along the longitudinal direction of the conductor 12, and the Y-axi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com