A positioning device for separated Hopkinson compression bar specimen

A Hopkinson pressure bar and positioning device technology, applied in measurement devices, analytical materials, instruments, etc., can solve problems such as errors, inconvenient positioning of specimens, and achieve the effect of accurate test data

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

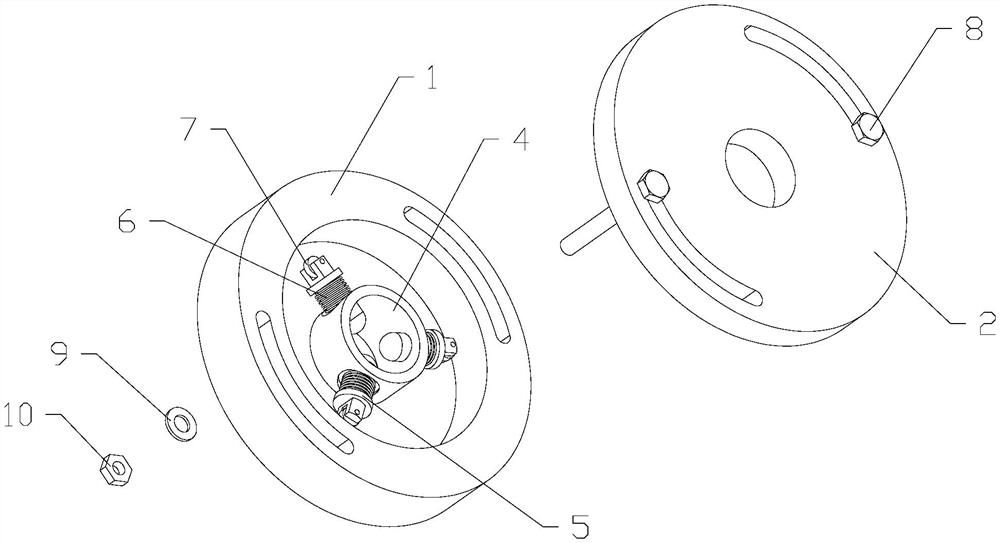

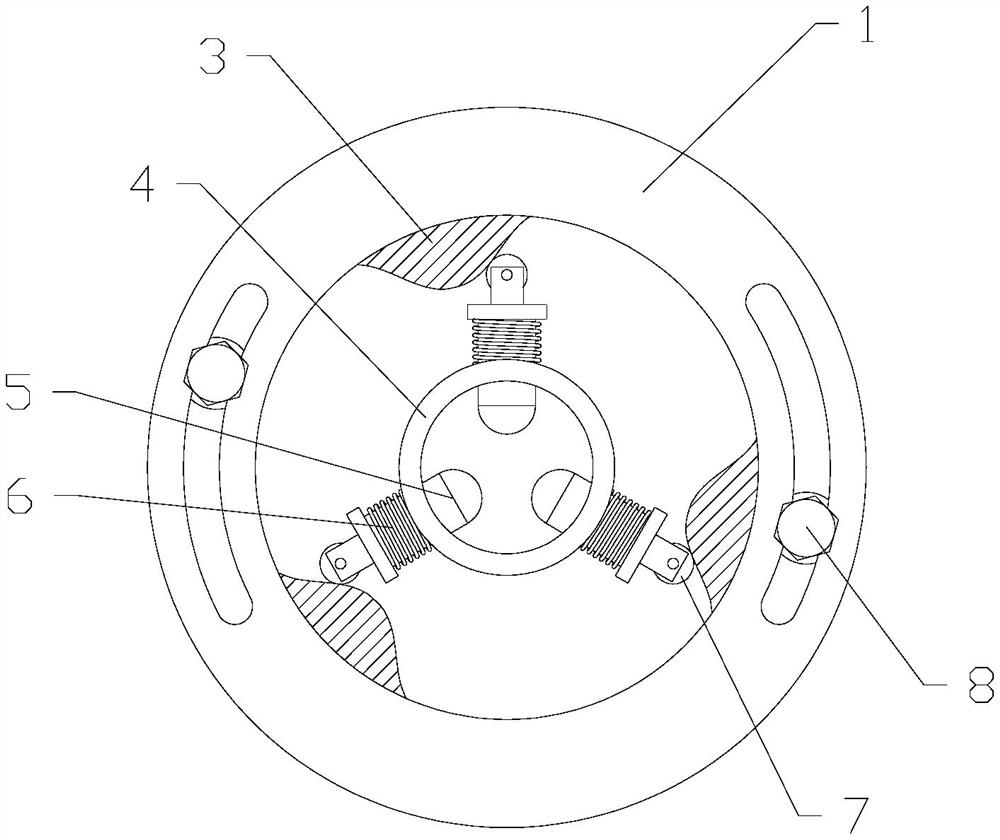

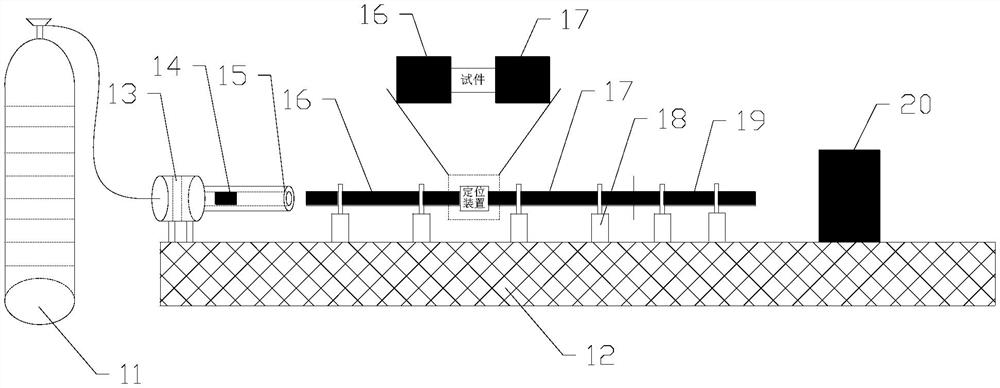

[0027] Please refer to figure 1 , the present embodiment provides a positioning device for a separate Hopkinson pressure bar test piece, which includes a carrier plate 1 equipped with a positioning element, a cam plate 2 and a connector for realizing the positioning of each size of the test piece, the carrier plate 1 and the The cam disc 2 is connected by a connecting piece, the connecting piece includes a bolt 8, a flat washer 9 and a nut 10, the positioning element includes an inner ring body 4, a driven rod 5, a spring 6 and a roller 7, the cam disc 2 in this embodiment, the bearing The material of the disk 1, the inner ring body 4 and the driven rod 5 are all aluminum alloys. There are three driven rods 5, and the three driven rods 5 are radially symmetrically distributed. The roller 7 is connected to the driven rod 5, and the spring 6 It is arranged on the driven rod 5, the driven rod 5 is connected to the inner ring body 4, and the inner side of the cam plate 2 is provid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com