A precision multi-channel structural glue dispensing device for automotive battery substrates

A technology for automobile batteries and glue dispensing devices, which is applied to devices and coatings that apply liquid to the surface, can solve problems such as troublesome replacement and adjustment of colloids, neglect of dispensing speed, dispensing volume and colloid parameters, etc. mixed effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

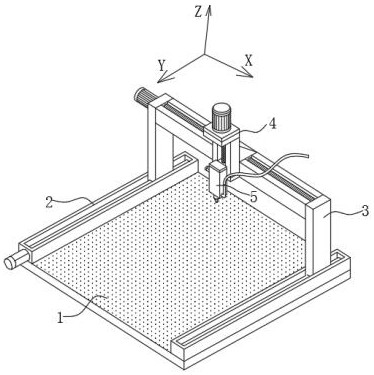

[0031] see Figure 1~7 , in an embodiment of the present invention, a precision multi-channel structural glue dispensing device for automotive battery substrates, which includes a processing table 1, a Y-direction driving arm 2, an X-direction driving arm 3, a Z-direction driving arm 4, and a dispensing Manipulator 5, wherein the Y-direction driving arm 2 is arranged on the processing table 1 for driving the X-direction driving arm 3 to move, the output end of the X-direction driving arm 3 is connected to the Z-direction driving arm 4, The output end of the Z-direction driving arm 4 is connected with the dispensing manipulator 5;

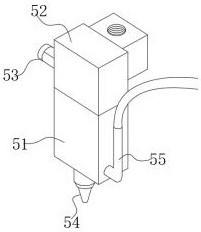

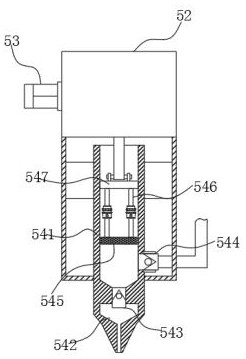

[0032] The dispensing manipulator 5 includes an installation warehouse 51, a drive assembly 52, a motor 53 and a dispensing head 54, wherein the dispensing head 54 is embedded in the installation warehouse 51, and it communicates with a glue supply hose 55 , the dispensing action of the dispensing head 54 is controlled by the motor 53 using the dri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com