Outer hexagon bolt automatic filling and rapid mounting device and working method thereof

An installation device and automatic filling technology, applied in metal processing, manufacturing tools, metal processing equipment and other directions, can solve the problems of unfavorable installation operation, slow installation efficiency, increase the labor intensity of operators, etc., to ensure stability and improve efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

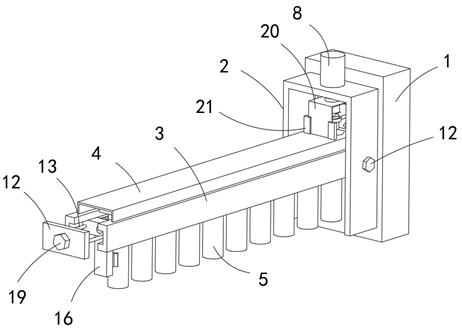

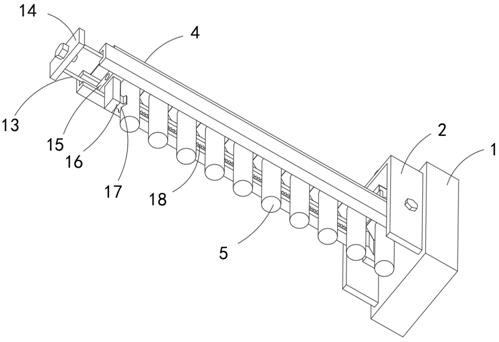

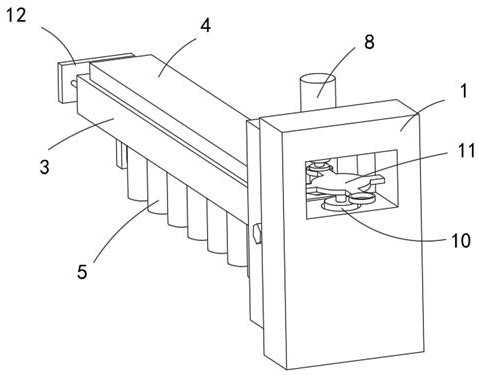

[0033] refer to Figure 1-7, a quick installation device for automatic loading of outer hexagonal bolts, comprising a rectangular frame 1, a U-shaped frame 2 is fixedly connected to the side wall of the rectangular frame 1, and two C-shaped plates 3 are fixedly connected to the inner wall of the U-shaped frame 2, C On the left and right side walls of shaped plate 3, all are fixedly connected with mounting block 27, and the outer wall of U-shaped frame 2 is screwed with the first knob 12 that is fixed with mounting block 11, and the side wall of mounting block 27 is provided with and the first knob 12 that is fixed with mounting block 11. The first thread groove matched by a knob 12, the C-shaped plate 3 is vertically arranged with the rectangular frame 1, and the notches of the two C-shaped plates 3 are arranged oppositely, and the upper ends of the two C-shaped plates 3 are fixedly connected with the same U-shaped connection Frame 4, the notch of U-shaped connecting frame 4 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com