A new energy vehicle wheel hub manufacturing and processing method

A technology for a new energy vehicle and a processing method, which is applied in the field of new energy vehicle wheel hub manufacturing and processing, can solve problems such as inconvenience and the wheel hub does not meet the use requirements, and achieve the effect of being easy to grasp and fix

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be described in further detail below in conjunction with the accompanying drawings.

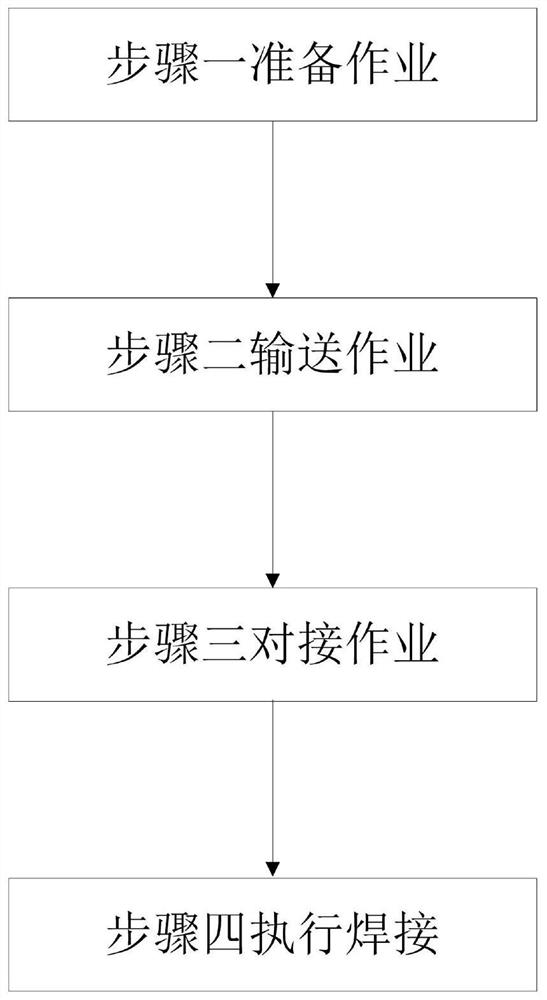

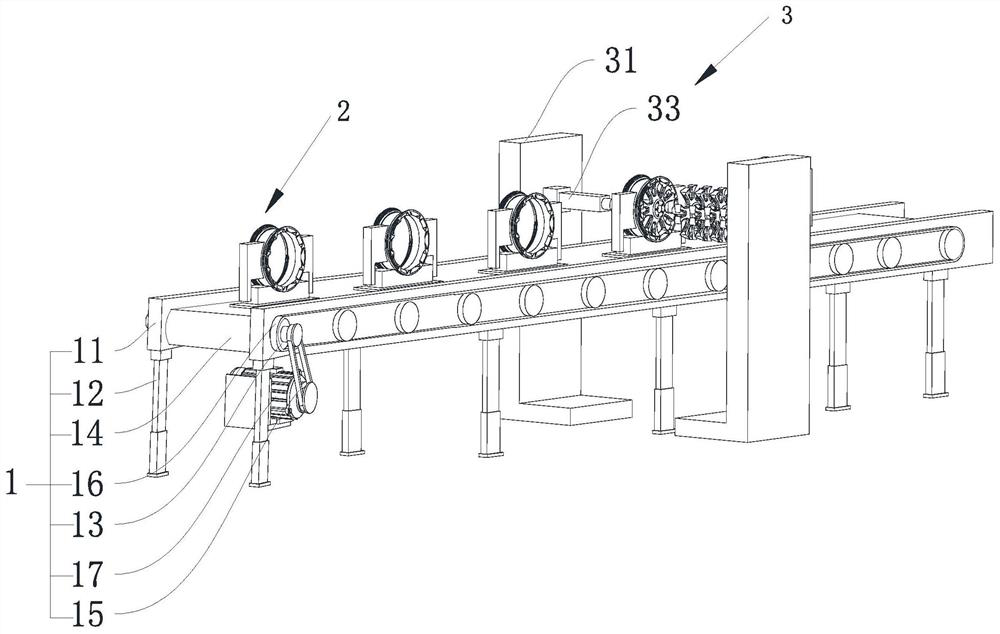

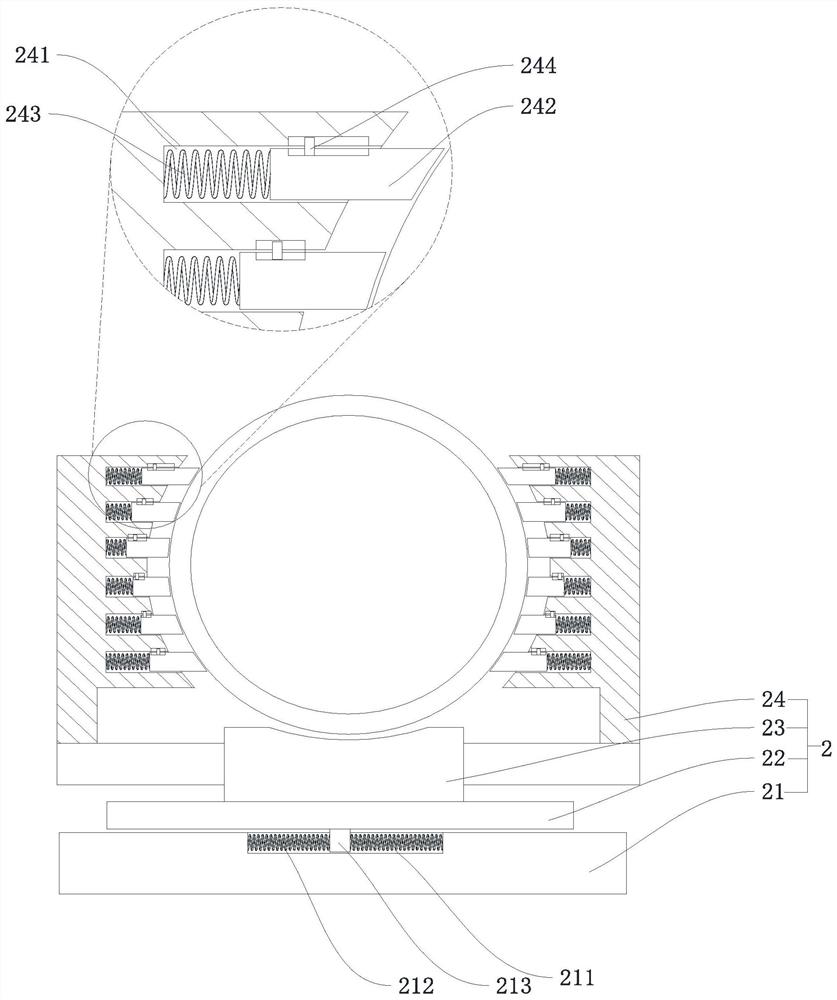

[0036] refer to Figure 1-8 As shown, it is a new energy automobile wheel manufacturing and processing method disclosed in the present invention, which uses an auxiliary processing equipment, which includes a transmission device 1, a fixing device 2, an erecting device 3 and a grabbing device 4, through the above device, during the production and processing of the wheel hub, the fixing device 2 fixes the rim, and transmits it to the next device area through the transmission device 1, and then the erecting device 3 and the grabbing device 4 match the spokes with the rim, and then fix the tube No. two two-way electric cylinder 341 in 34 drives the block 345 that is connected with connecting rod 344 rotations by support rod 342, adjusts the position in the wheel rim to the spoke on the grasping device 4, finally welds and fixes. The above device does not need t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com