Tapping machine tool capable of achieving multidirectional positioning and fixing and used for plate machining

A technology for sheet metal and machine tools, which is applied in the field of tapping machine tools for sheet metal processing, and can solve the problems of reducing sheet production efficiency, single sheet size, and increasing production costs, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029]Next, the technical solutions in the embodiments of the present invention will be apparent from the embodiment of the present invention, and it is clearly described, and it is understood that the described embodiments are merely embodiments of the present invention, not all of the embodiments. Based on the embodiments of the present invention, there are all other embodiments obtained without making creative labor without making creative labor premises.

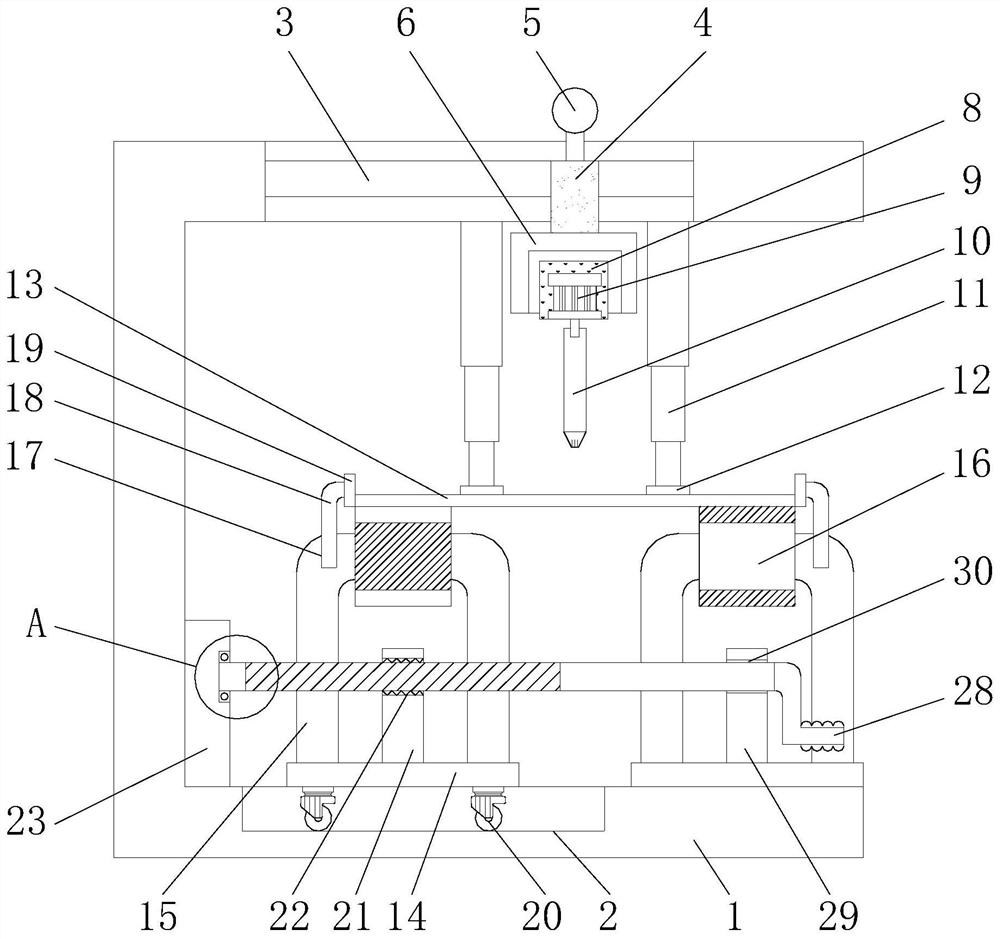

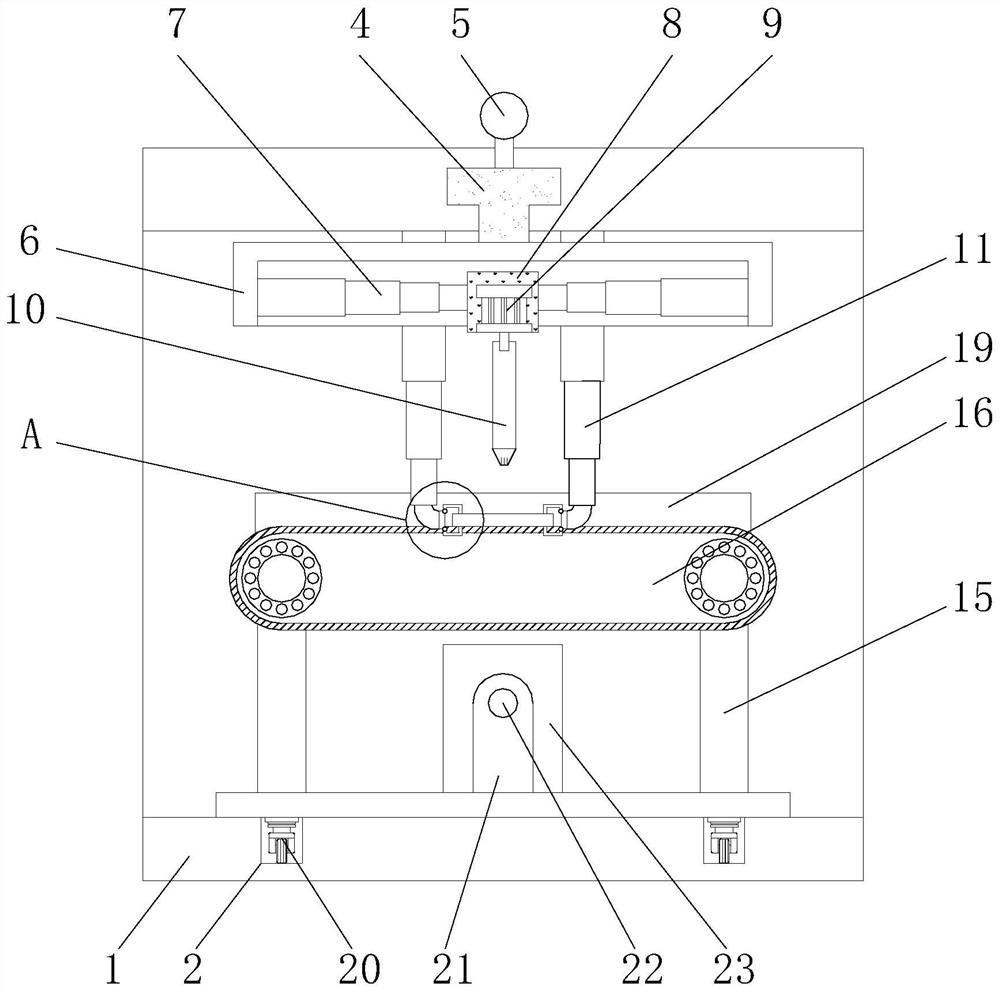

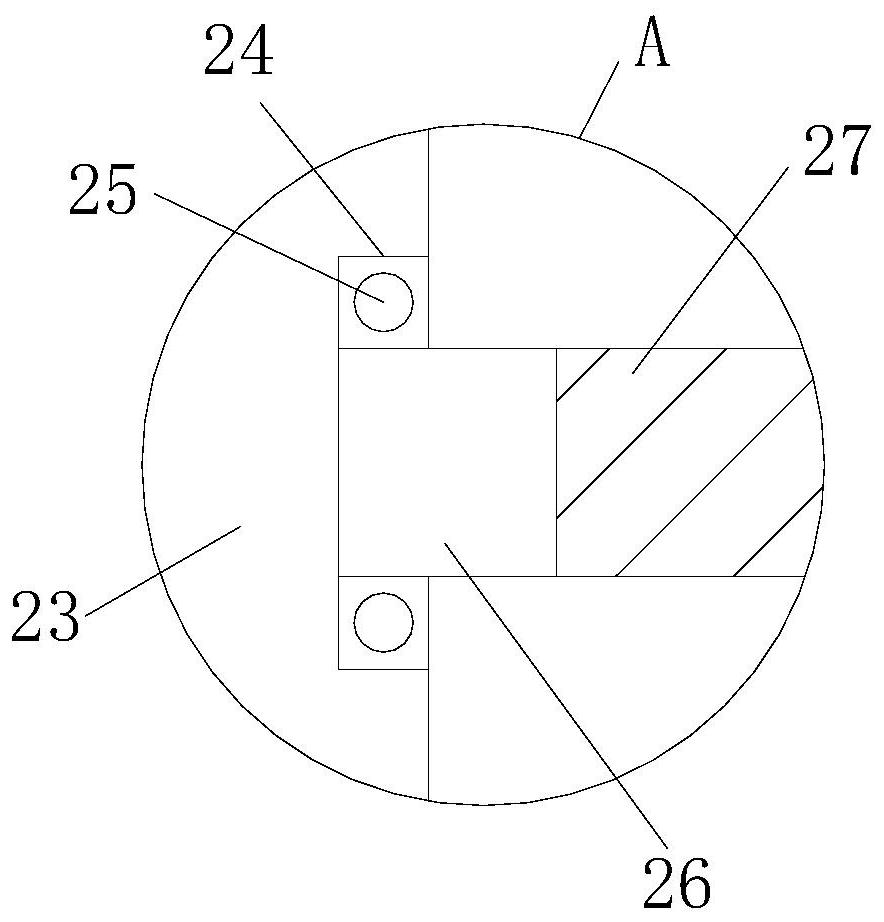

[0030]SeeFigure 1-7The present invention provides a technical solution: a tapping machine tool for multi-directional fixed plate, including fixed base 1, slide rail 2, shaped chute 3, shaped slider 4, handbill 5, fixing frame 6, the electric telescopic rod 7, the fixing block 8, the motor 9, the tapping drill bit 10, the electric push rod 11, the electric graphic hand 12, the plate semi-finished product 13, the bottom plate 14, the support frame 15, the transfer device body 16, the fixed slot 17, The support rod 18, the baffle 19...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com