Blade battery connector

A technology of battery connectors and connectors, which is applied in the direction of contact parts, fixed/insulated contact components, etc., can solve problems such as melting tin, tin climbing on the plug-in end of the terminal group, and achieve the effect of easy rework processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0027]Embodiment:

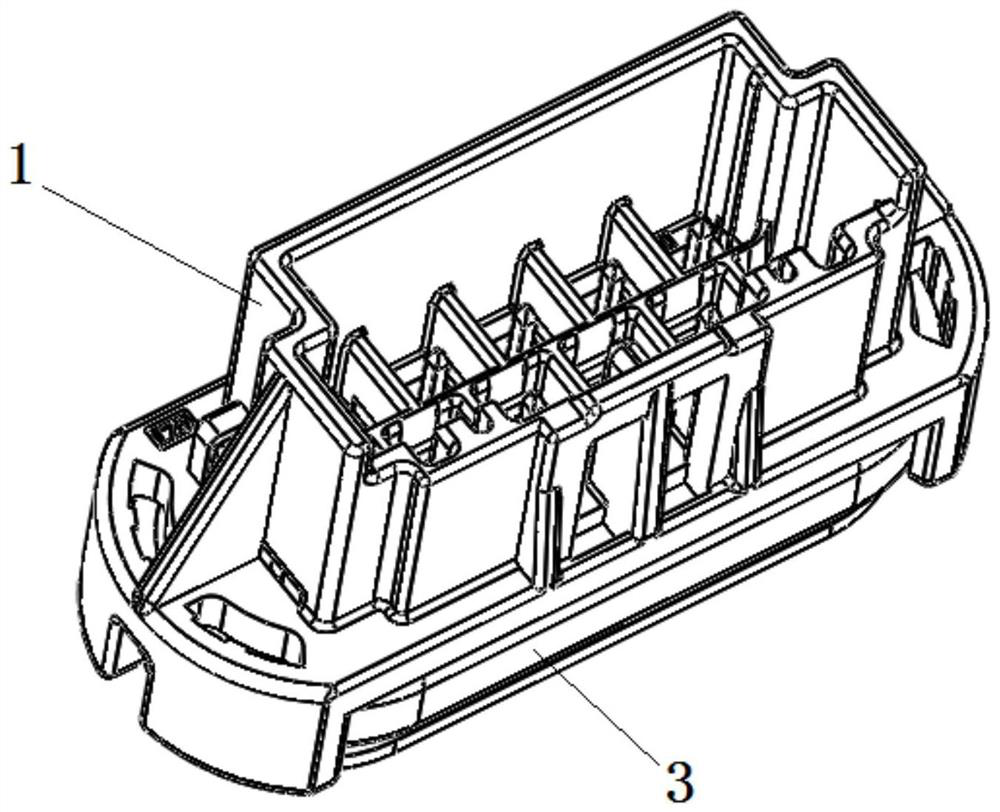

[0028]Such asfigure 1 As shown, a blade battery connector proposed in the present application, the connector includes a connector housing 1, an insulator 3, a terminal group, and a terminal fixing member (not shown in the figure).

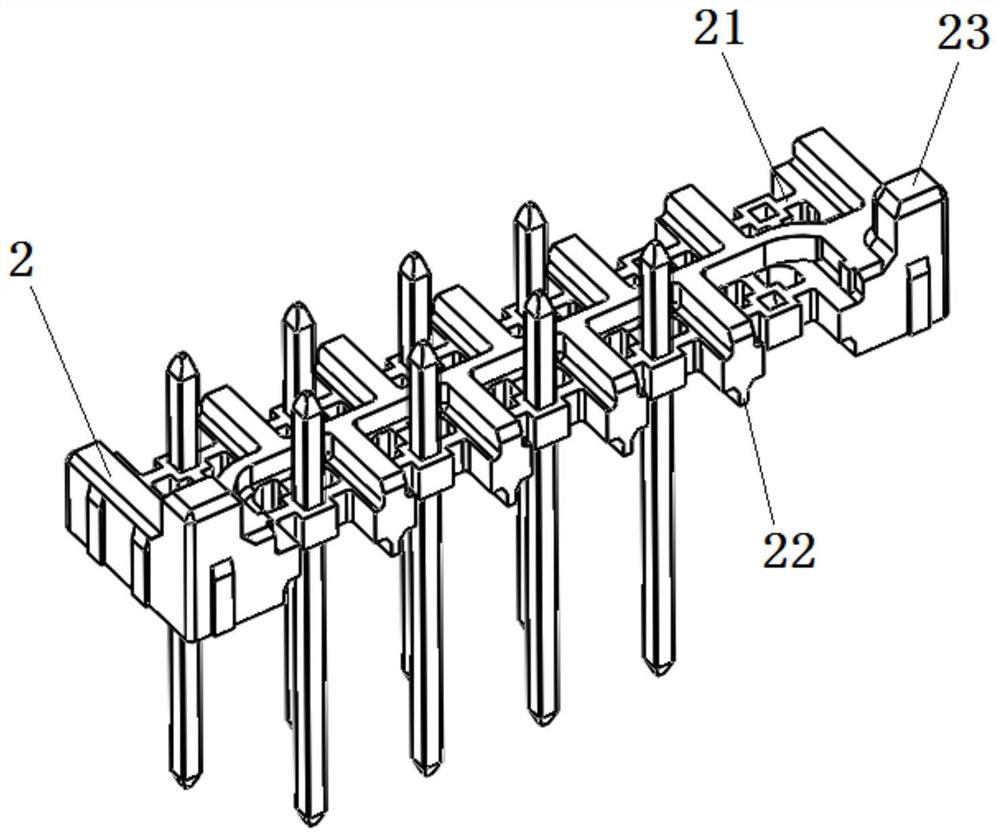

[0029]Such asfigure 2 As shown, the intermediate section of the terminal group is fixed to the terminal fixing member 2 in the intermediate section of the terminal group, and the upper and lower sides of the terminal fixing member 2 are the socchip end and the weld end. The terminal fixing member 2 isolates the welding end and the socchip end of the terminal group, and the terminal fixing member 2 is connected between the terminal group (the INSERT MOLDING mode can be achieved), and the tin block is solved in the soldering process. After melting, the problem of climbing the tin in the insertion end.

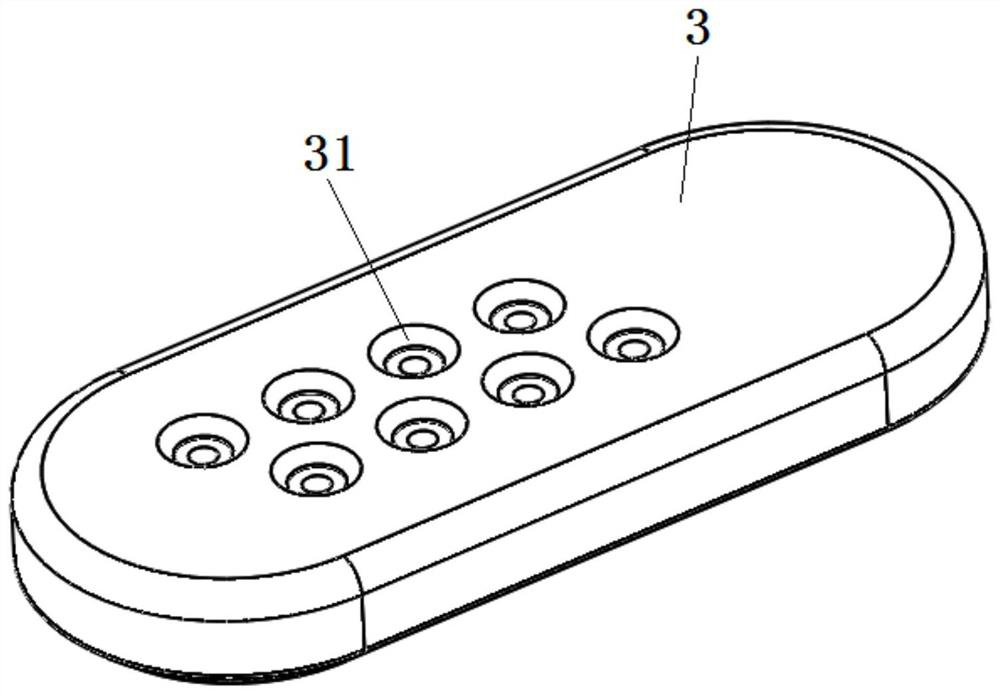

[0030]Such asFigure 5 As shown, the terminal fixing member 2 is provided above the insulator 3 and is welded by the welded end and the insulator...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap