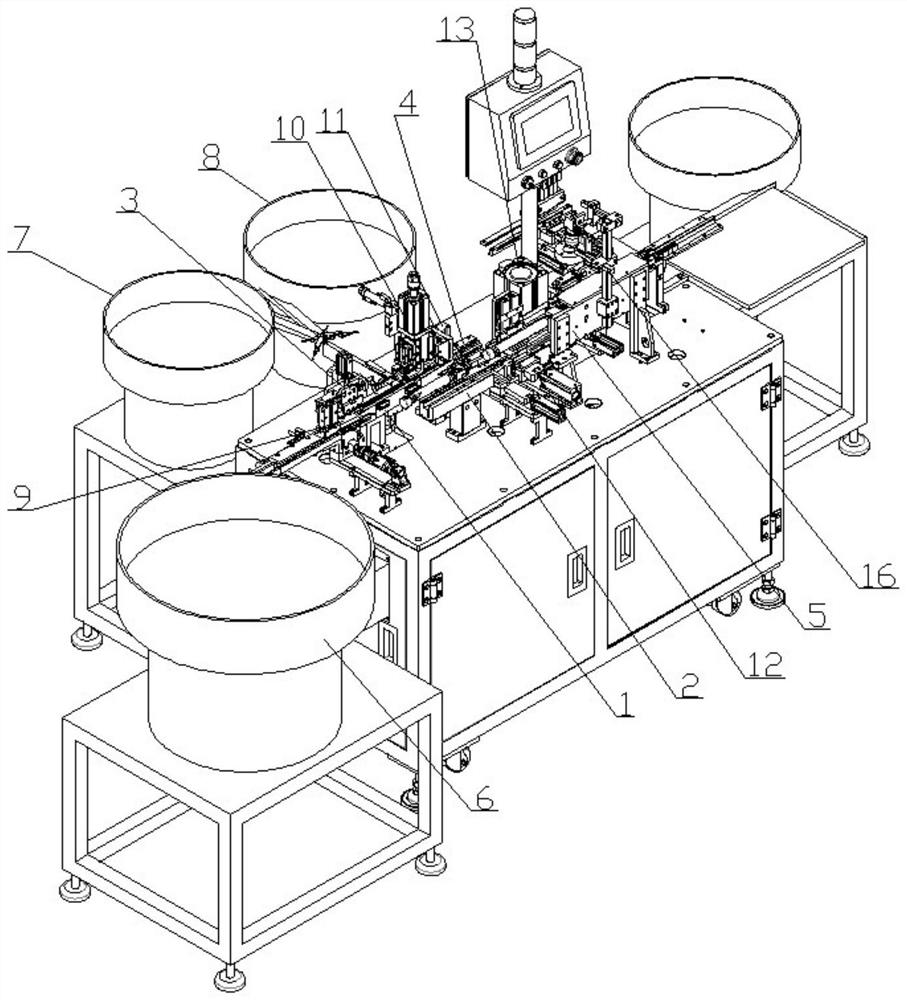

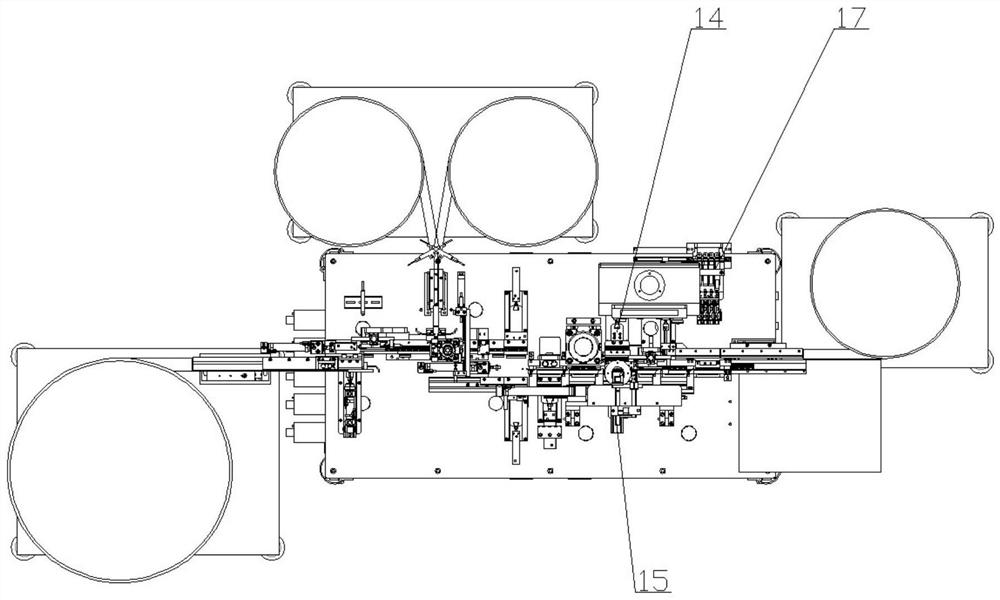

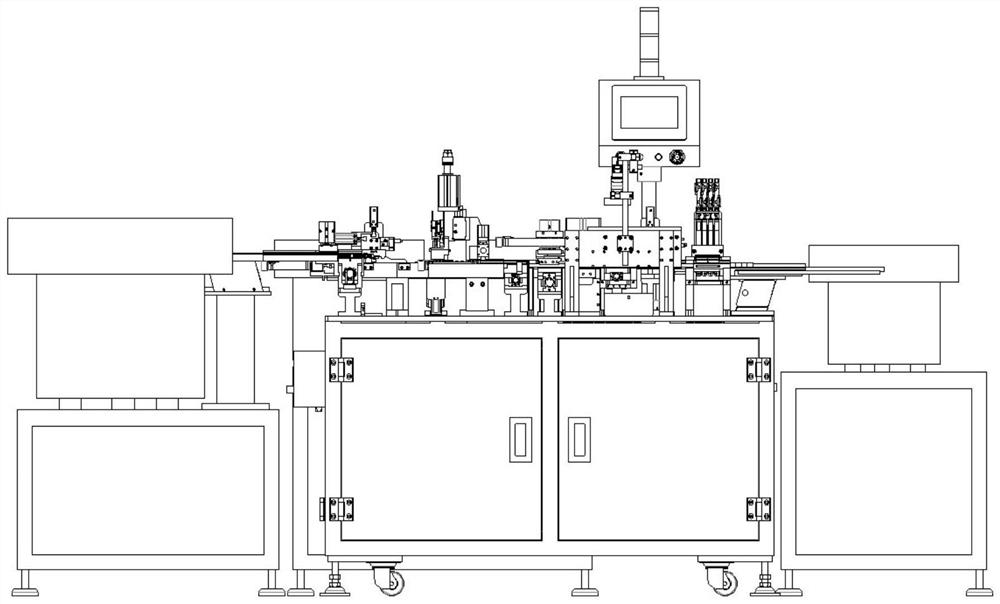

Bending foot connector led lamp assembly machine and its matching assembly method

A technology of LED lamp group and LED lamp, which is applied in the direction of assembly/disassembly of contact parts, etc., can solve the problems of unfavorable automatic wiring welding operation, low production efficiency, small size of LED lamp, etc., so as to facilitate automatic wiring welding operation and reduce wiring Difficulty, the effect of ensuring that they are level with each other

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to make it easier for those skilled in the art to fully understand the technical solution disclosed in the present invention, before describing in detail the assembly machine of the bent-pin connector LED lamp, a general description of the structure of the bent-pin connector is given as follows: The connector is mainly composed of an insulating plastic body, a terminal block, a rear cover, a first LED light, and a second LED light. Wherein, along its width direction, a series of installation slots are arrayed on the bent pin connector. Before the official implementation of the assembly process of the LED lamp, the connection terminals are pre-inserted and fixed in the above-mentioned installation grooves. In addition, along its height direction, a first slot and a second slot are opened on the insulating plastic body for inserting the first LED lamp and the second LED lamp respectively. The first LED lamp is composed of a first LED lamp body and a first lamp p...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap