Tiltable runway type lifting machine for vehicle

A runway type and lift technology, which is applied in the field of inclinable runway type lifts for vehicles, can solve the problems of poor safety, unable to meet the lifting requirements of vehicles, and single function.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described in conjunction with the accompanying drawings and specific embodiments.

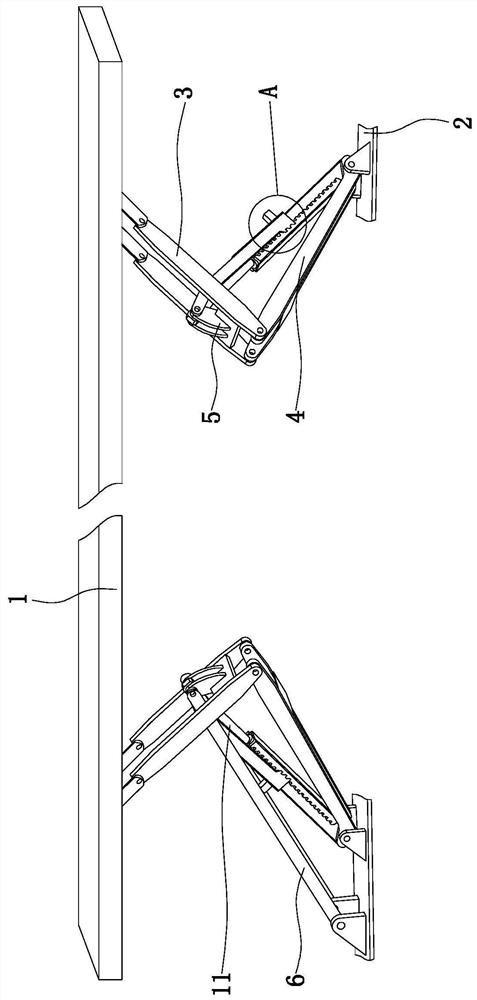

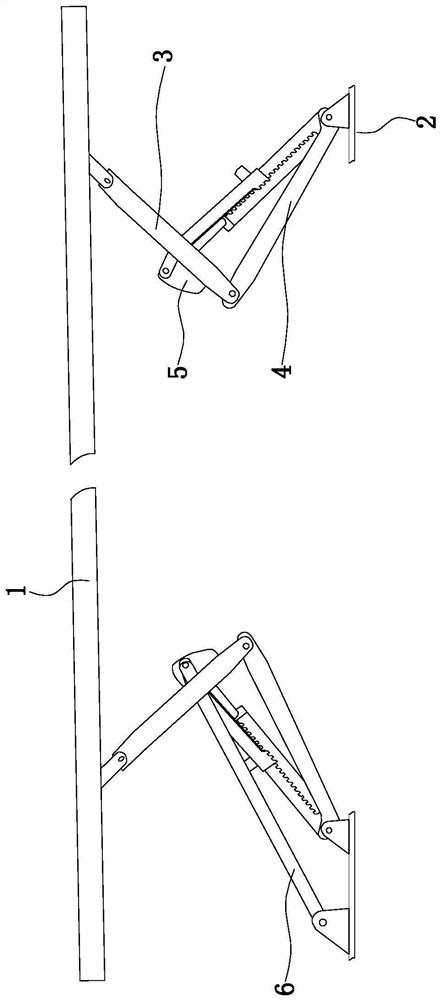

[0028] see Figure 1 to Figure 5 As shown, the technical solution adopted in this embodiment is:

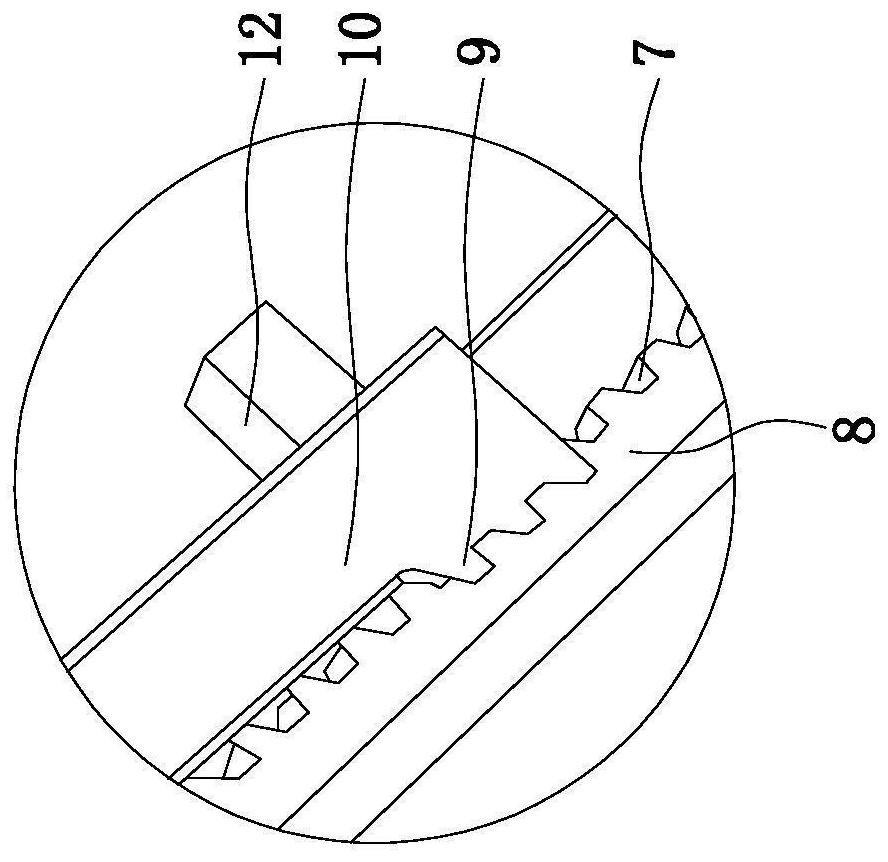

[0029] An inclineable runway lift for vehicles, including a load-bearing plate 1 for supporting a car, and lifting devices respectively arranged at the left and right ends of the load-bearing plate 1 for lifting the load-bearing plate 1, and the two lifting devices are symmetrically arranged on the load-bearing plate 1. At both ends of the plate 1, the lifting device includes a support base 2 for connecting with the ground, a drive frame 3 rotatably arranged on the load-bearing plate 1 at one end, a support frame 4 rotatably arranged on the support base 2 at one end, and a rotatable fixed end The telescopic end that is arranged on support base 2 can rotate and be arranged on the elevating driving device 11 on the driving frame 3, the other end of drivi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com