A hydraulic press equipment for forming irregularly curved panels

A curved plate and hydraulic press technology, applied in the field of mechanical equipment manufacturing, can solve the problems of complex operation of equipment, difficult processing, and difficulty in making various irregular lines, so as to achieve the effect of simple and convenient drill and meet the needs of high precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

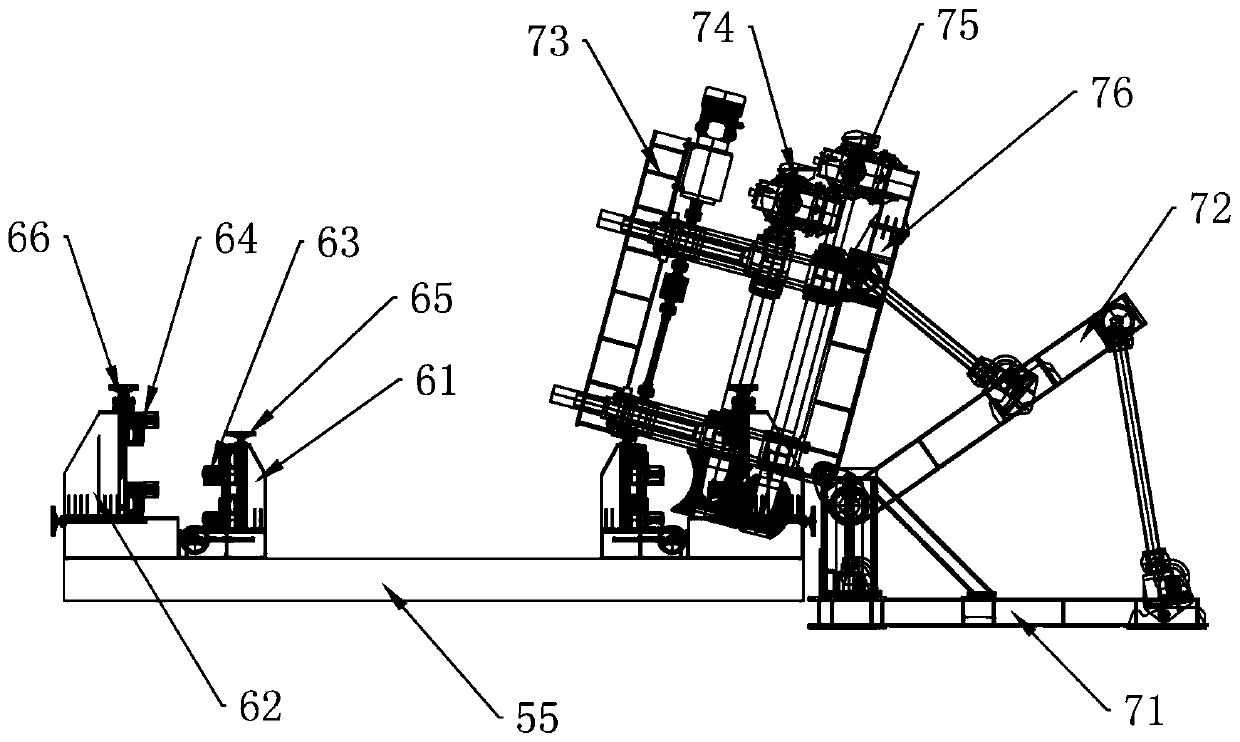

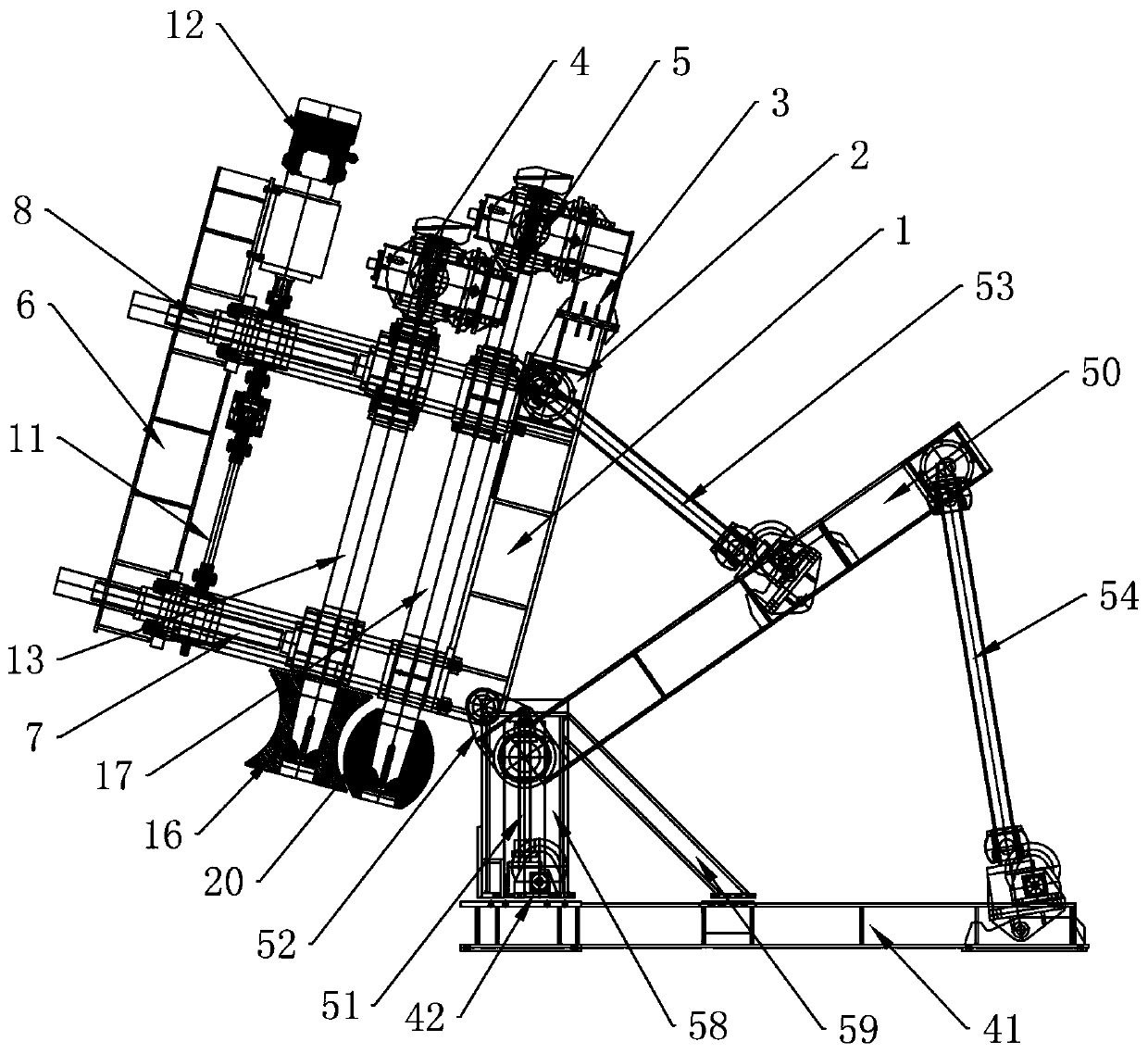

[0037] In further embodiments of the present invention, please continue to refer to Figure 1 to Figure 8 As shown, the first base 41 is arranged in an L shape. The first base 41 includes a first mounting base 56 and a second mounting base 57. The connecting base 42 is located on the upper side of one end of the first mounting base 56. The first mounting base 56 The other end of the second mounting base 57 is connected with one end, the second support 44 is located on the upper side of one end of the second mounting base 57, and the first support 43 is located on the upper side of the other end of the second mounting base 57.

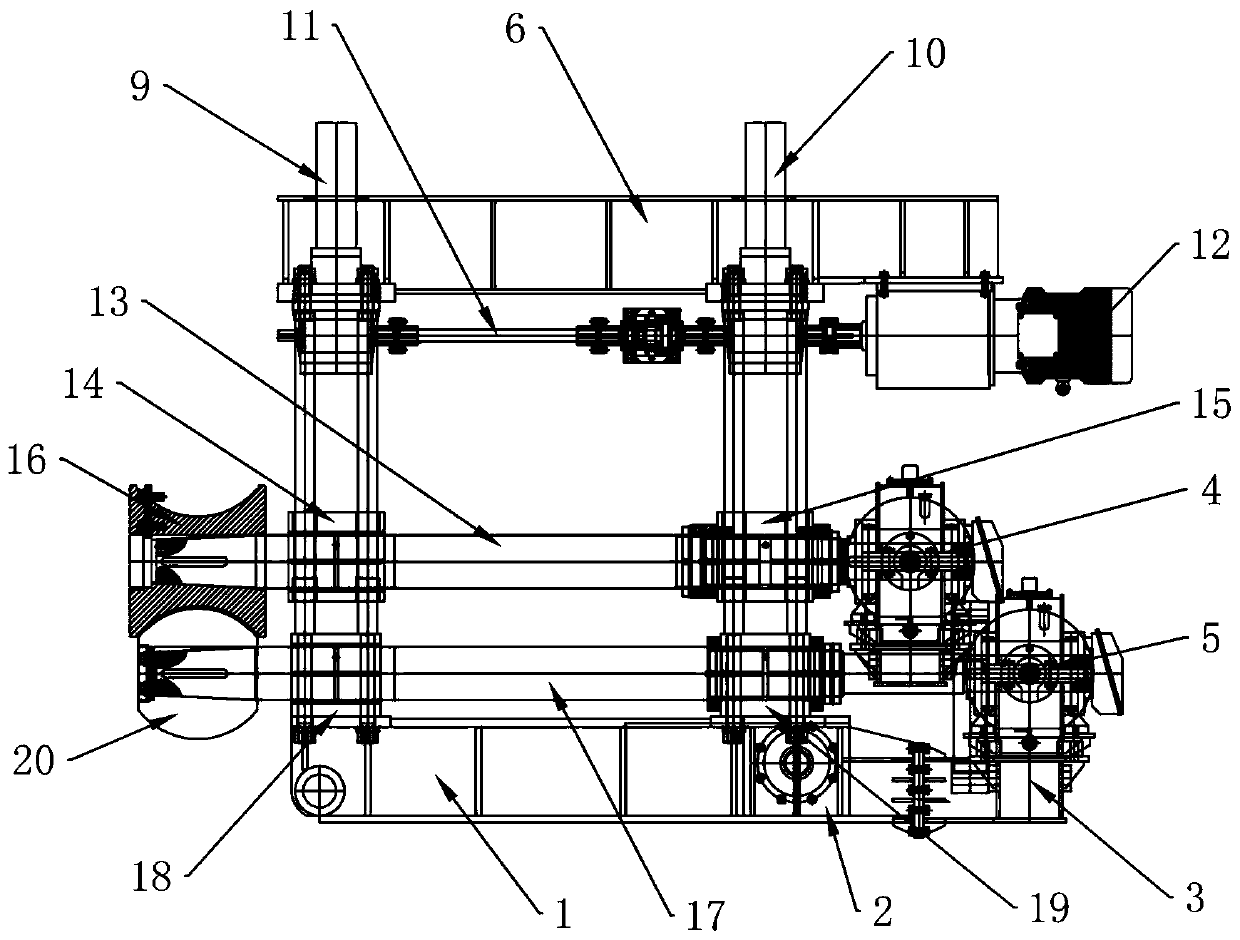

[0038] In a further embodiment of the present invention, the movable base 1 and the third mounting base 2 are vertically arranged, and one end of the third mounting base 2 is rotationally connected with the other end of the first telescopic roller 53, and the upper rolling motor 4 and the lower rolling motor 5 Both are installed on the upper side of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com