Garage supporting component and garage

A technology for supporting members and garages, applied in the field of garages, can solve the problems of high structural cost, declining economic advantages, and being inferior to large column nets, etc., to achieve the effect of reducing construction costs and improving the sense of space in the garage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

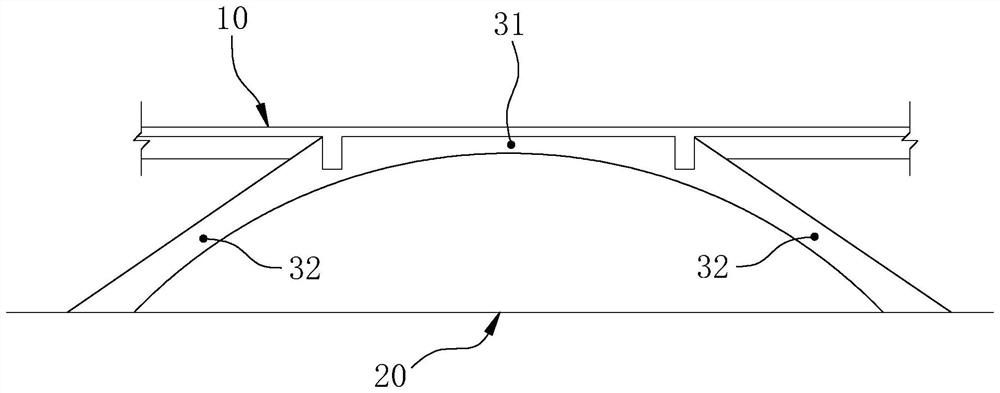

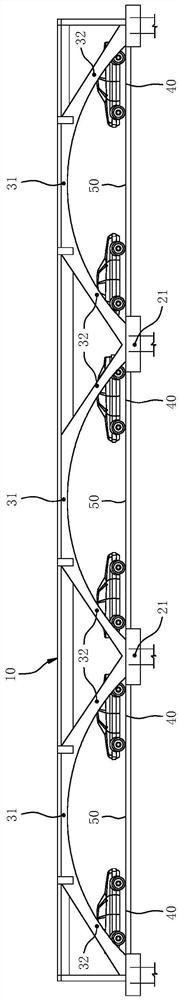

[0038] like figure 2 As shown, a certain garage with the same size as Comparative Example 1 includes a garage floor, and a garage support member is arranged in the garage floor, and the garage support member includes a support beam 31 for being arranged at the bottom of the beam-slab member 10 and a The slanting support columns 32 arranged on the garage floor 20; the slanting support columns 32 are two, and the upper ends of the two slanting support columns 32 are respectively connected with the two ends of the support beam 31; the upper side of the support beam 31 It is a support plane, and its lower side is a concave arc surface; the lower side of the inclined supporting column 32 is an arcuate surface, and the lower side of the supporting beam 31 and the lower sides of the two inclined supporting columns 32 are connected smoothly to form an arch Shaped structure; the garage floor is provided with at least two garage support members distributed side by side, and the diagona...

Embodiment 2

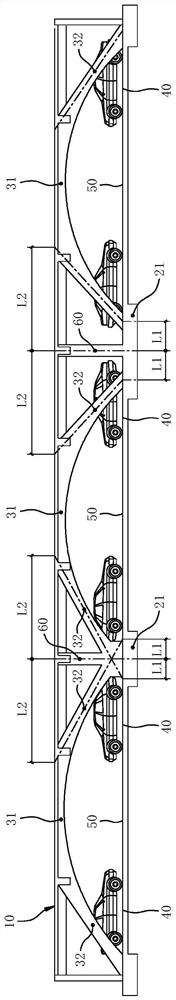

[0044] like image 3 As shown, a certain garage with the same size as Comparative Example 1 includes a garage floor, and a garage support member is arranged in the garage floor, and the garage support member includes a support beam 31 for being arranged at the bottom of the beam-slab member 10 and a The slanting support columns 32 arranged on the garage floor 20; the slanting support columns 32 are two, and the upper ends of the two slanting support columns 32 are respectively connected with the two ends of the support beam 31; the upper side of the support beam 31 It is a support plane, and its lower side is a concave arc surface; the lower side of the inclined supporting column 32 is an arcuate surface, and the lower side of the supporting beam 31 and the lower sides of the two inclined supporting columns 32 are connected smoothly to form an arch shaped structure; the garage floor is provided with at least two garage support members distributed side by side, and the diagonal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com