Automatic poultry slaughtering machine and method

A kind of poultry and automatic technology, applied in poultry processing, poultry transmission/conveying device, slaughtering, etc., can solve the problems of large manpower consumption, low safety, low slaughtering efficiency, etc., and achieve the effect of improving the efficiency of subsequent slaughtering

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

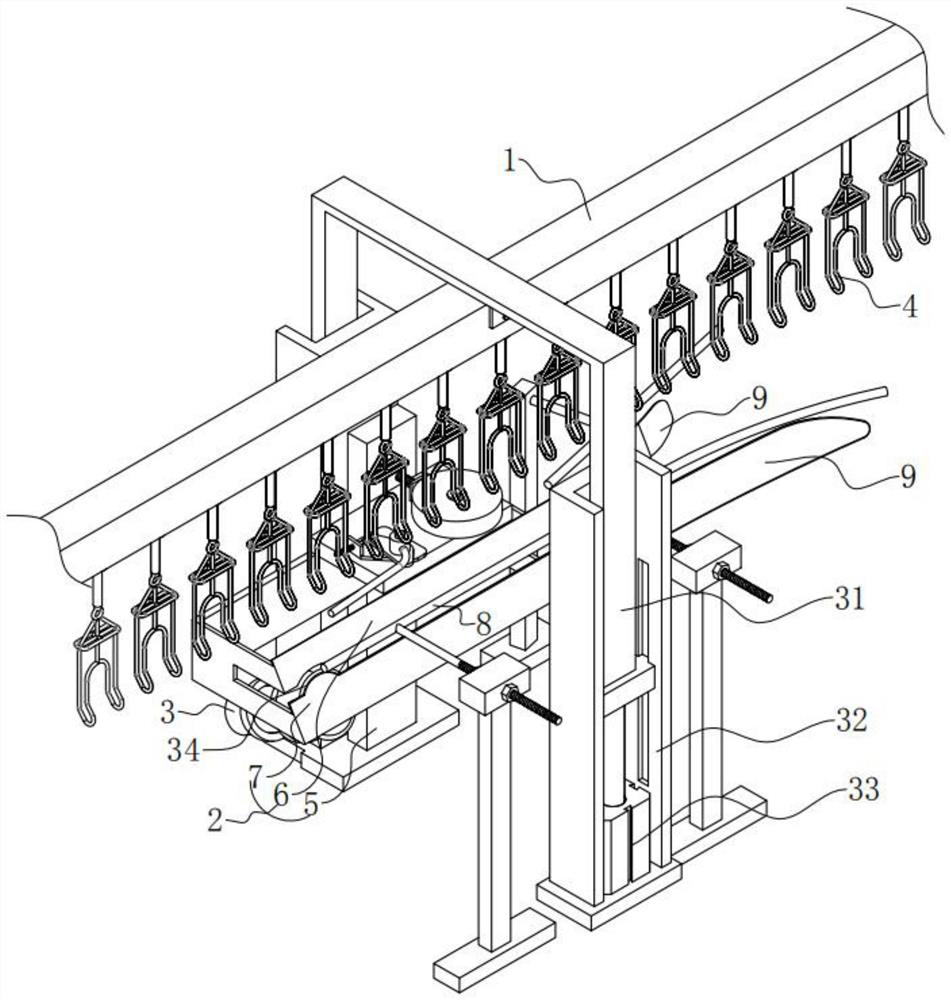

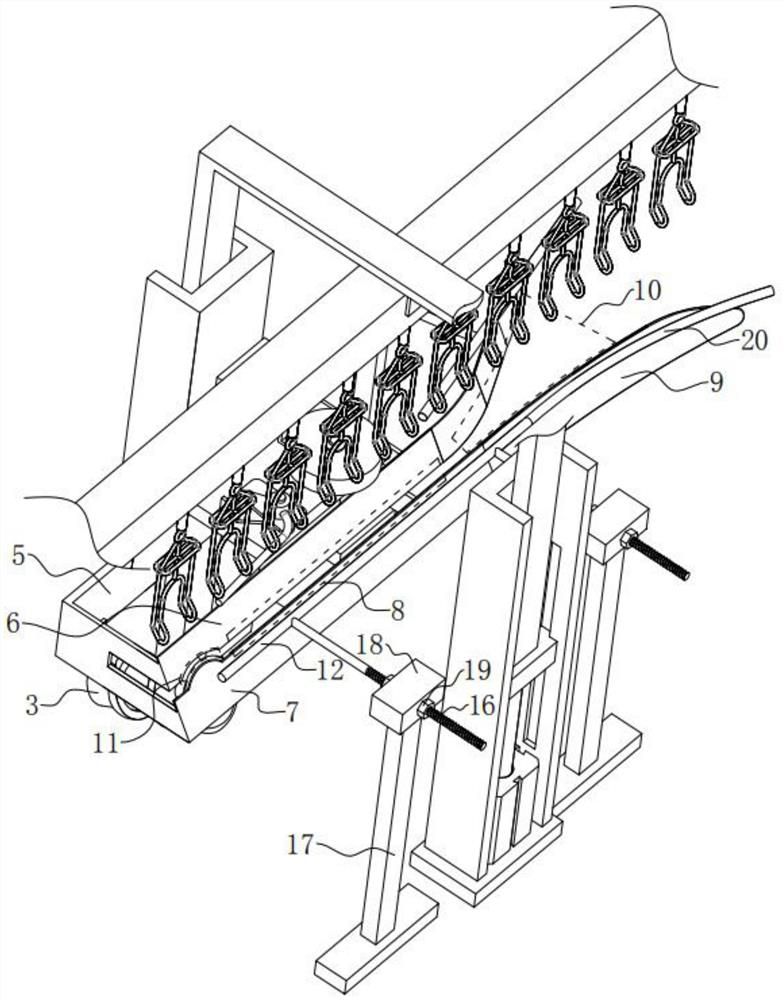

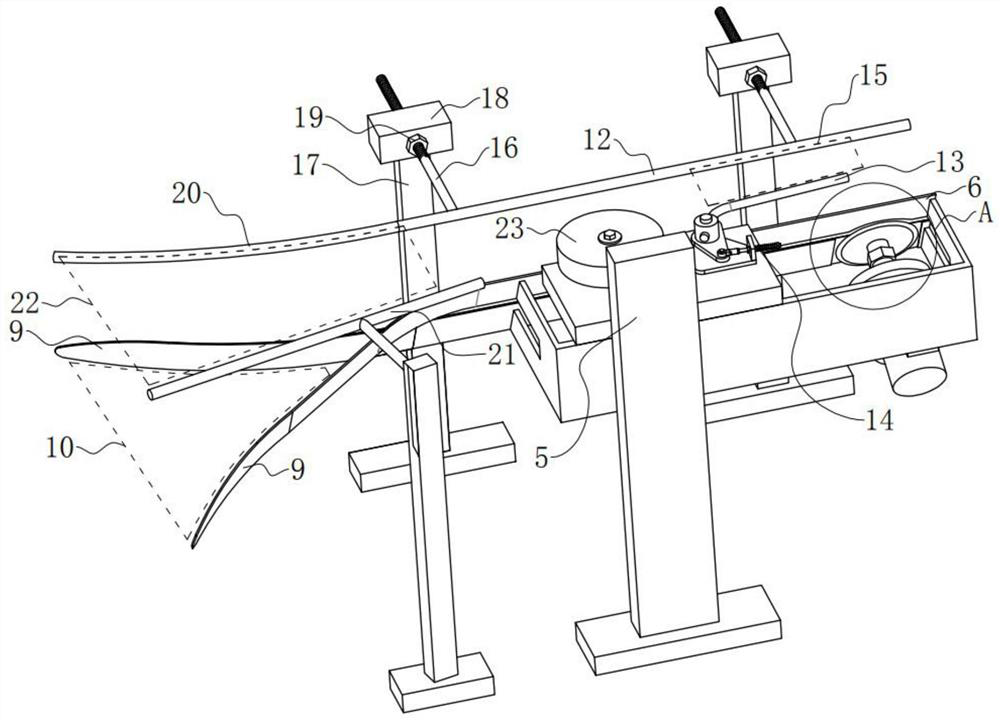

[0026] In order to describe the technical content, achieved goals and effects of the present invention in detail, the following descriptions will be made in conjunction with the embodiments and accompanying drawings. It should be noted that the words "upper" and "lower" used in the following description refer to the attached image 3 And attached Figure 5 In the directions, the words "bottom" and "top" refer to the attached figure 1 in the direction towards the geometric center of a particular part.

[0027] The most critical idea of the present invention is: through the leg fixing frame 4, the effect of fixing the stunned poultry to be slaughtered upside down on the conveying device 1 is realized; The function of transporting and improving the efficiency of subsequent slaughtering; through the feeding guide part 9 and the guide channel 10, while initially defining and adjusting the position of the neck of the poultry to be slaughtered, it is convenient to better guide th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com