Large electromechanical equipment heat dissipation control method and device

A technology of electromechanical equipment and control methods, which is applied in the direction of cooling/ventilation/heating transformation, modification with gaseous coolant, etc., can solve the problem of high heat dissipation efficiency, achieve the effects of improving reliability and life, reducing impact, and reducing the range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0061] In order to deepen the knowledge and understanding of the present invention, the technical solutions of the present invention will be further introduced below in conjunction with the accompanying drawings and specific embodiments.

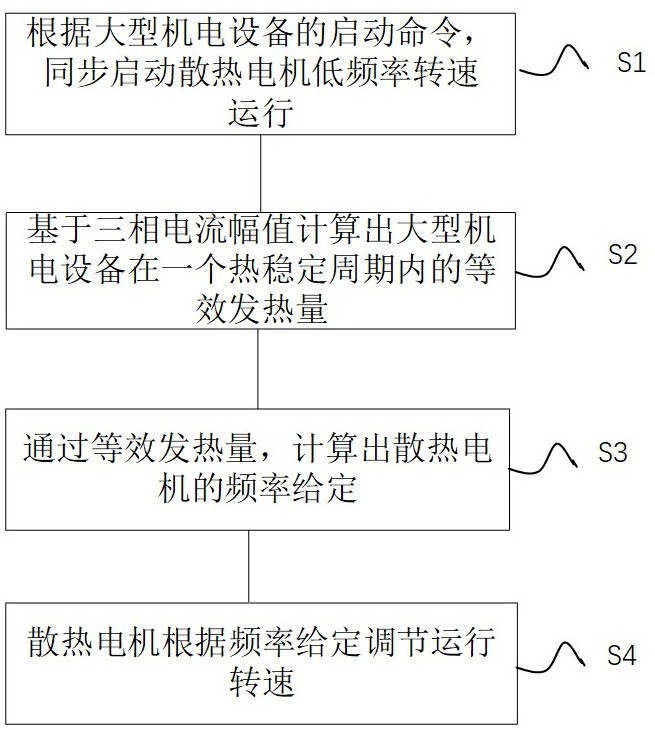

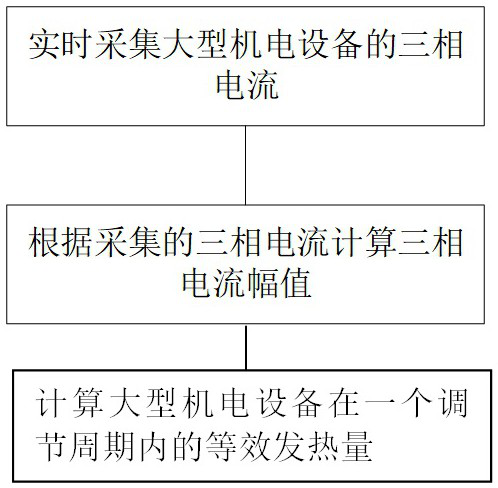

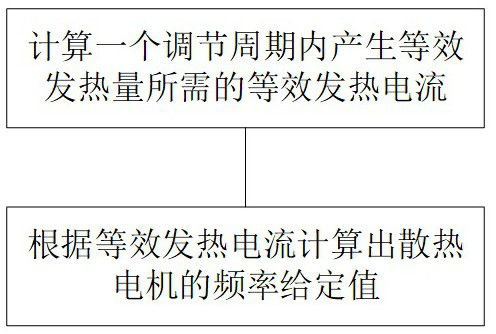

[0062]The heat dissipation system of large electromechanical equipment consists of heat dissipation motor, heat dissipation air duct, frequency converter for driving heat dissipation motor, temperature monitoring of large electromechanical equipment, and air duct partial pressure detection. In order to improve the heat dissipation efficiency of large electromechanical equipment, improve the timeliness of heat dissipation, and reduce the thermal shock of large electromechanical equipment. The invention provides a heat dissipation control method for large-scale electromechanical equipment. According to the operation information of the large-scale electromechanical equipment, the heat dissipation loss is calculated, and the operating frequency o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com