Enhanced formation testing double packer

A formation testing, double packer technology, applied in the directions of sealing/packing, measurement, wellbore/well components, etc. Improve practicability, reduce transportation and use costs, facilitate disassembly and separate transportation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

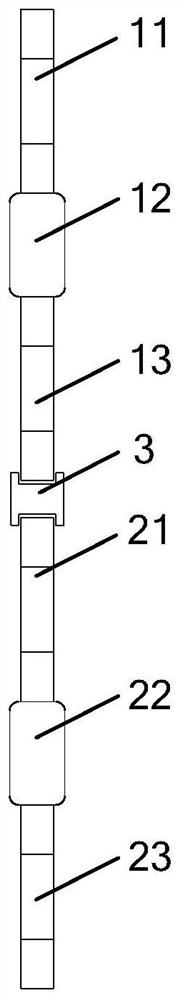

[0019] In order to make the purpose, technical solution and advantages of the application clearer, the embodiments of the application will be described in detail below in conjunction with the accompanying drawings. It should be noted that, in the case of no conflict, the embodiments in the present application and the features in the embodiments can be combined arbitrarily with each other.

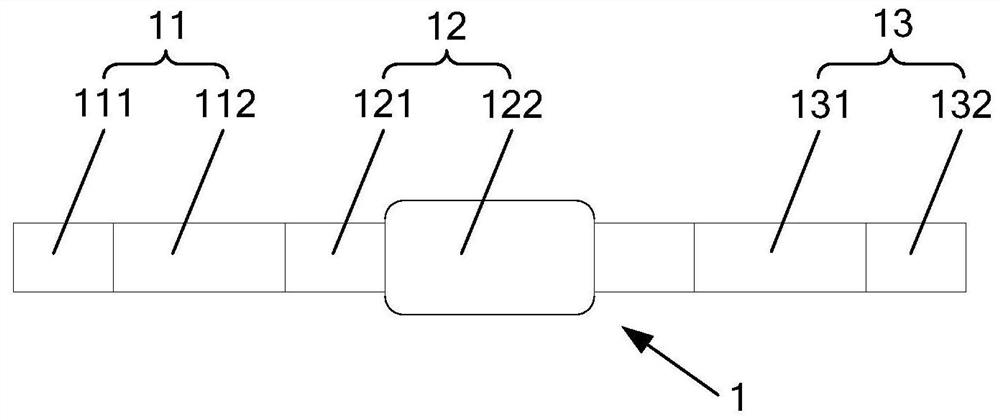

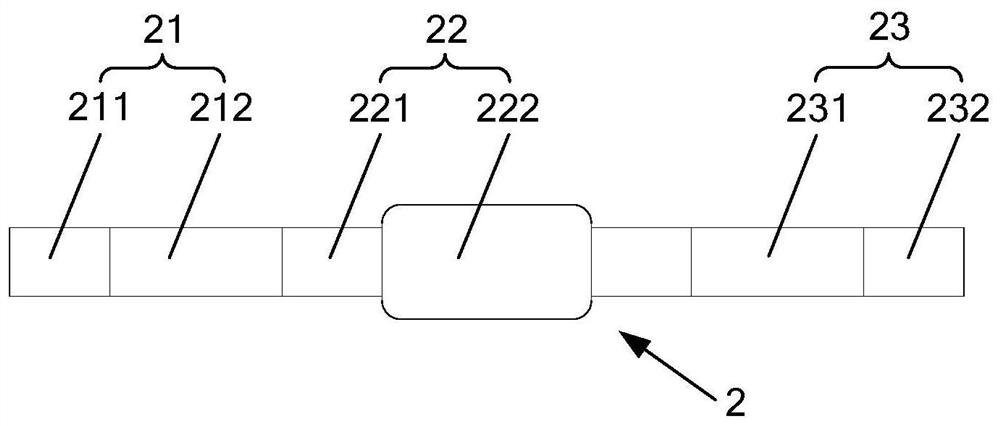

[0020] The existing double packer is an integral structure, which cannot be disassembled for separate transportation. In the case of a long overall length of the double packer, the transportation cost is greatly increased, which is not conducive to the maintenance, transportation and maintenance of the double packer. operation, and it is also easy to cause damage to the double packers. Moreover, the span between the upper packer and the lower packer in the double packer is fixed, and the scope of application is small, so it cannot be widely used in downhole operations under different well c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com