Folded plate drying bed, sludge dryer based on folded plate drying bed and wastewater treatment method

A dryer and sludge technology, applied in water/sludge/sewage treatment, dehydration/drying/concentrated sludge treatment, chemical instruments and methods, etc., can solve incomplete degradation, low solid content, sterilization High energy consumption and other issues, to achieve the effect of reducing transportation and use costs, short carbonization time, and high solid content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

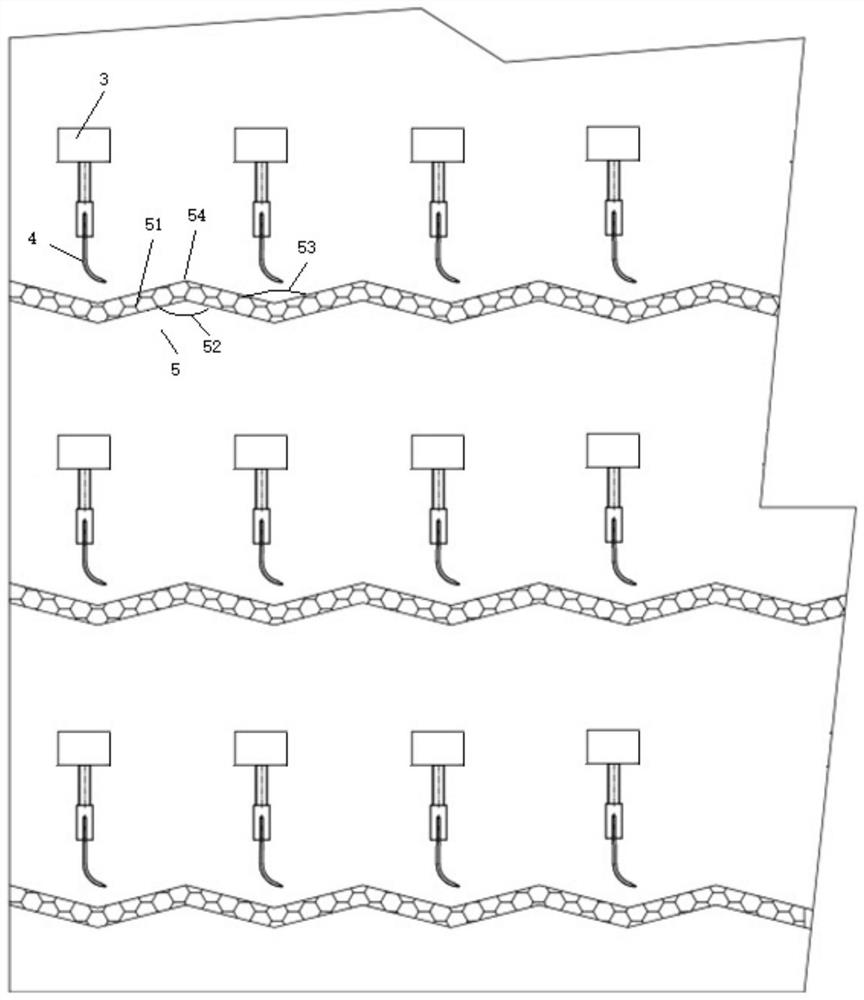

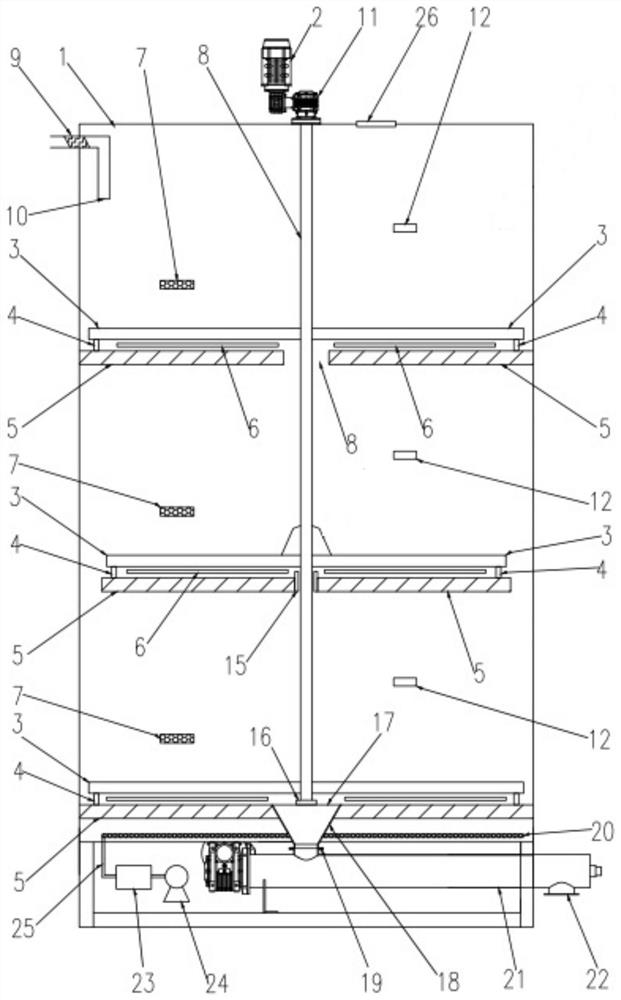

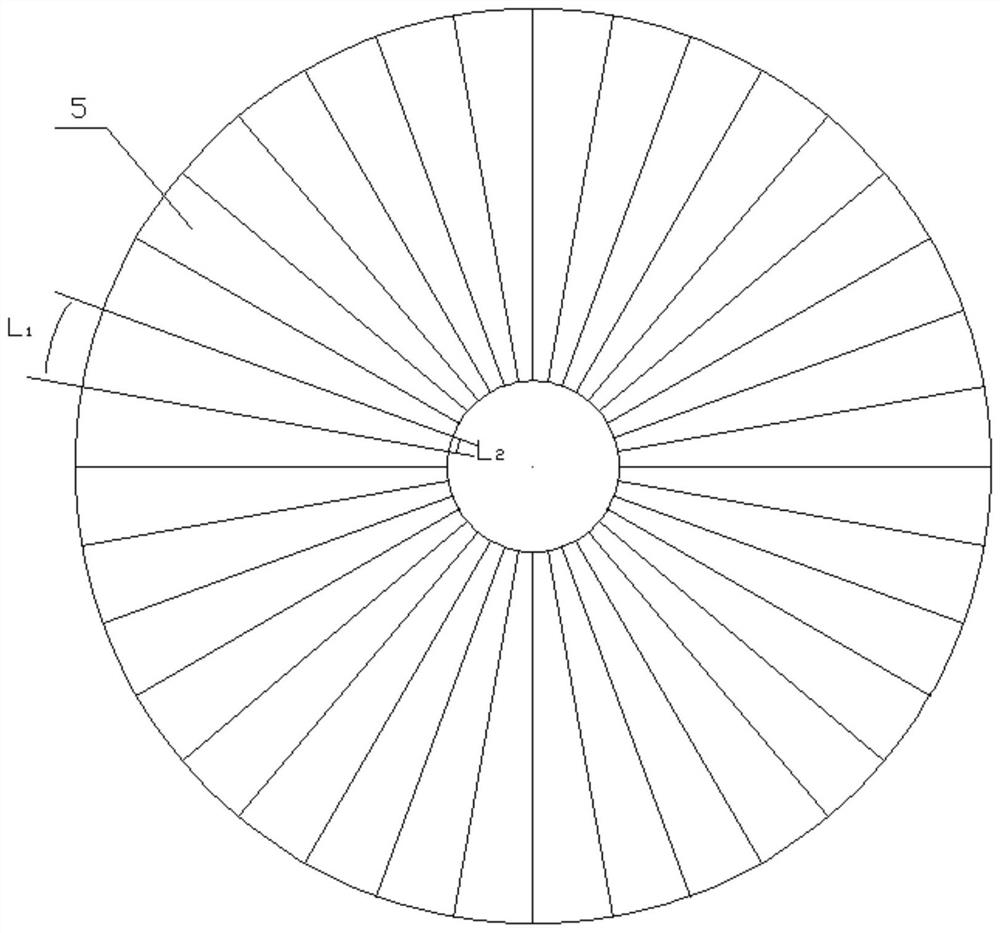

[0037] Such as figure 1 , a folded plate drying bed, comprising a folded plate 5, a throwing mechanism, and a hot air blowing mechanism. The folded plate 5 is a thin-wall space formed by a number of narrow and long thin plates 51 alternately intersecting at an obtuse angle 1 52 and an obtuse angle 2 53. body, the obtuse angle one 51 is towards the folded plate 5 below, and the obtuse angle two 53 is towards the folded plate 5 top; the folded plate 5 is also arranged with ventilation holes 54 in the following manner: the ventilation holes 54 are arranged along the longitudinal direction of the thin plate 51, and all the ventilation holes 54 is arranged near the obtuse angle two 53; the throwing mechanism includes a cantilever 3 arranged at intervals above the folded plate 5, a scraper 4 arranged along the lengthwise direction of the cantilever 3, and a cantilever that can be driven to translate and alternately pass through all the folded plates 5 above. The driving mechanism of...

Embodiment 2

[0044] Use the drier of embodiment 1 to carry out the method for wastewater treatment, may further comprise the steps:

[0045] S1. After stirring and homogenizing the sludge and sewage mixture in public toilets, filter through the grid to remove large pieces of garbage, fibers, and large particles of slag;

[0046] S2. The filtered sludge and sewage mixture is centrifuged and dehydrated to obtain filtrate and mud with a solid content of 35% to 45%;

[0047] S3. Send the mud to the sludge dryer based on the folded plate drying bed, the mud is turned over and flattened on the multi-layer folded plate from top to bottom, and exchanged with the hot air passing through the folded plate After heating, dry to obtain granular materials with a solid content of not less than 60%, which meets the index requirements of "Mud for Urban Sewage Treatment Plant Sludge Disposal and Landscaping" (GB / T 23486-2009), and then transported by the The device is discharged, the thickness of the granu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com