A kind of screw steel hot rolling manufacturing process

A manufacturing process and rebar technology, applied in the field of rebar hot rolling manufacturing process, can solve the problems of incomplete forming, reducing the effect of rebar forming, and excessive deformation of the steel bar, so as to avoid excessive deformation, improve the success rate, The effect of improving efficiency

Active Publication Date: 2022-06-03

宁夏建龙龙祥钢铁有限公司

View PDF6 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0005] The invention can solve the problem that the existing equipment cannot carry out secondary pressing treatment on the steel bar when the rebar is pressed and formed, and the steel bar is prone to incomplete forming after pressing, thereby reducing the effect of rebar forming and reducing the rebar forming effect. At the same time, the rebar after forming cannot be rectified, and the rebar is prone to excessive deformation during pressing, and it cannot be ensured that the rebar is kept straight during pressing, and the rebar after pressing is prone to bending phenomenon, thereby reducing the effect of rebar forming and other problems

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

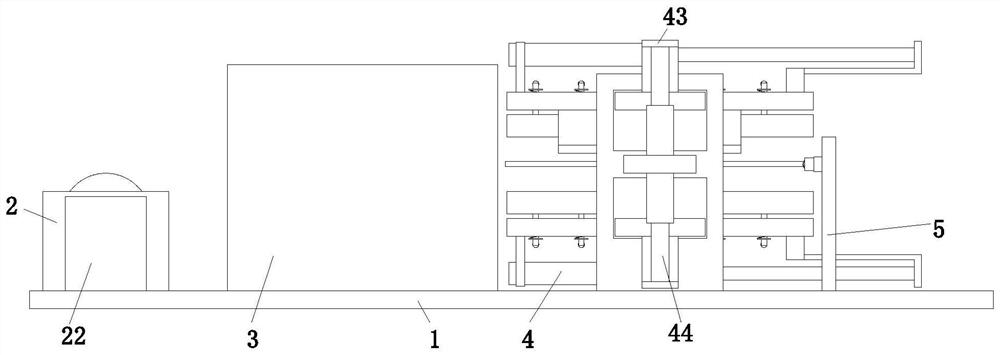

[0044] Described profiling device 4 includes a support plate 41, a closing board 42, a jacking frame 43, a two-way cylinder 44, a profiling mechanism 45,

[0048] The rolling mechanism 47 includes a rolling cylinder 471, a rolling frame 472 and a lower pressing roller 473.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

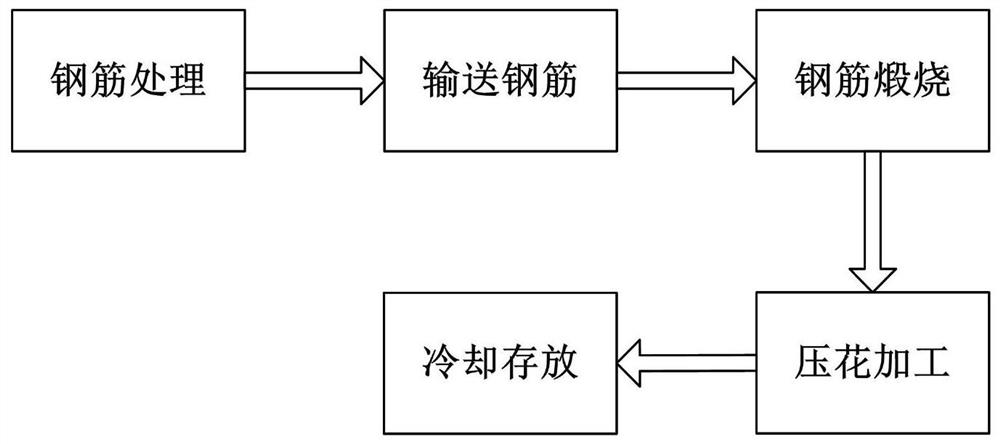

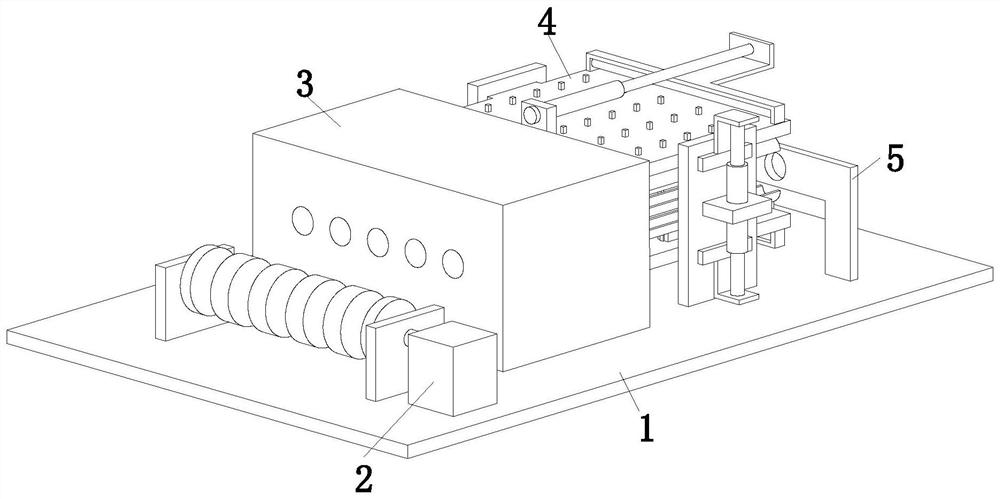

The invention relates to a hot-rolled manufacturing process of rebar, including a main board, a conveying device, a heating furnace, a pressing device and a molding device, a conveying device is installed on the upper end of the main board, a heating furnace is arranged on the right side of the conveying device, and the heating furnace is installed on the main board On the right side of the heating furnace, there is a profiling device installed on the main board, and on the right side of the profiling device is a molding device. The present invention can solve the problem that the existing equipment cannot carry out secondary pressing treatment on the steel bar when pressing and forming the threaded steel, and the steel bar is prone to incomplete forming after pressing, which reduces the success rate of the threaded steel forming, and at the same time, cannot The formed rebar is rectified, and the rebar is prone to excessive deformation during pressing, and it cannot be ensured that the rebar remains straight during pressing. effects and other issues.

Description

A kind of hot rolling manufacturing process of rebar technical field [0001] The present invention relates to the technical field of steel processing, in particular to a manufacturing process for hot rolling of rebar. Background technique Rebar is a ribbed steel bar on the surface, also called ribbed steel bar, usually with 2 longitudinal ribs and uniform along the length direction. Distributed transverse ribs, the shapes of transverse ribs are spiral, herringbone, and crescent shapes. The ribs on the surface of rebar are usually hot-rolled. Process, rebar is a medium-sized and above construction component must be made of steel, due to the action of ribs, rebar is different from concrete. Larger bonding capacity, thus increasing the ability to withstand external forces, so rebar is widely used in various building structures, especially Large, heavy, light thin-walled and high-rise building structures. At present, when existing equipment is pressed and formed for reb...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): B21C37/04

CPCB21C37/045

Inventor 曾志伟唐国斌

Owner 宁夏建龙龙祥钢铁有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com