Labor-saving device used for repairing vacuum tire through rubber strip

A technology of tubeless tires and rubber strips, applied in the field of civil machinery, can solve the problems of misalignment of tire repair parts, uneven quality, unsafe driving of cars, etc., and achieve the effect of ensuring center alignment, large feeding force and slow movement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] DETAILED DESCRIPTION OF THE PREFERRED EMBODIMENTS

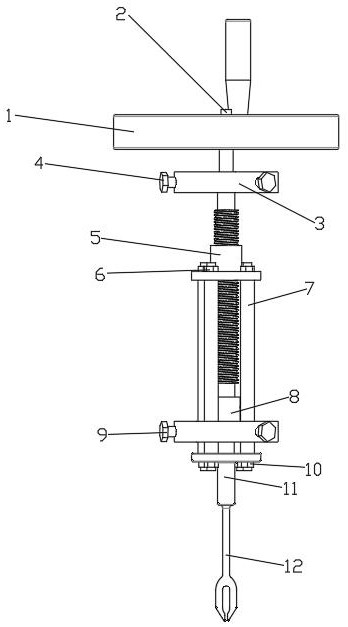

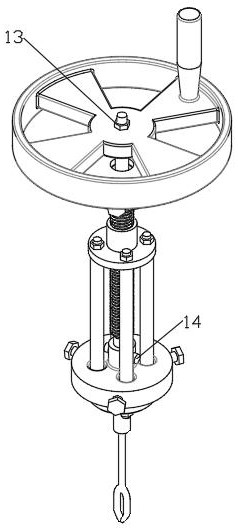

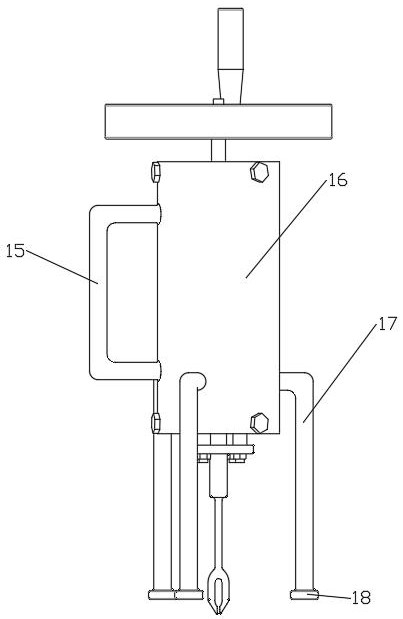

[0014] The present invention is connected by a hand wheel (1), a wire bar post (2), a upper end cap (3), a housing-upper cover connection screw (4), a transmission nut (5), a link nut (6), and connecting rod (7) ), Lower end cover (8), housing - lower end cover connection screw (9), link nut (10), connect base (11), plug (12), hand wheel fixing nut (13), lead wheel limit Bolts (14), handle (15), housing (16), fixed column (17), rubber block (18), rolling bearing (19); for easy understanding, the device is divided into moving parts, moving parts, motion and The fixed mating components are discussed separately.

[0015] Sportswear: figure 1 , 2 3, 4, the hand wheel (1) and the wire bar post (2) are connected to the handwheel fixing nut (13) through the upper end of the screw column; the transmission nut (5) and the connecting base (11) The link (7) is fixed to the connecting base (11) by the connecting rod (7) and the transm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com