A graphene-based self-melting snow pavement structure with shape memory function

A self-melting snow pavement, graphene-based technology, applied in the direction of on-site coagulation pavement, roads, roads, etc., can solve the problem of poor conductivity, crack resistance and durability of conductive asphalt, harsh application environment of graphene heating film, The existing pavement has problems such as short service life, and achieves the effect of reducing the downward heat transfer, good heat conduction, and increasing electrical conductivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

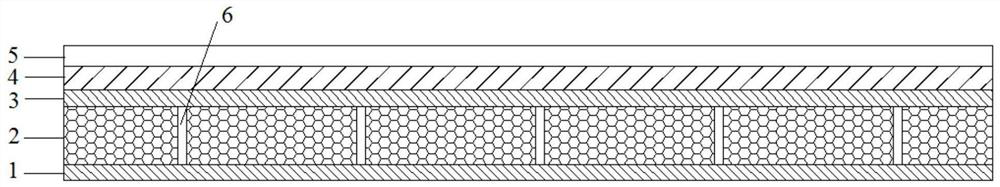

[0034] DETAILED first embodiment: Graphene-based self-melting snow Pavement structure of the present embodiment having shape memory embodiment comprises from bottom to top of the insulating layer laid on a pavement, asphalt graphene based conductive layer 2, a shape memory polymer layer 3, the insulating layer 4 and the surface layer of asphalt 5; the graphene layer spacing pitch based conductive plurality of electrodes arranged within 6 2; the insulating layer 1, a graphene based conductive asphalt layer 2, the shape of memory polymer layer between the asphalt layer 3 and the insulating layers adjacent to the interface 4 respectively emulsified asphalt adhesive bonding, the surface layer 5 is laid on the insulating layer 4 asphalt;

[0035] The graphene based conductive asphalt layer 2 parts by weight of 5 parts to 10 parts of asphalt, 70 parts to 120 parts of aggregate, 15 to 20 parts mineral powder, a conductive shape memory composites, modified graphene oxide , carbon fiber; w...

specific Embodiment approach 2

[0050] DETAILED Embodiment 2: This embodiment differs from the specific embodiment is an embodiment: the shape memory polymer layer 3 is a thermotropic shape memory polymer, a shape memory polymer electrochromic type, a thermosetting or thermoplastic shape memory polymer a shape memory polymer, a thickness of 0.3cm ~ 0.5cm. Other steps are the same as a specific embodiment.

specific Embodiment approach 3

[0051] DETAILED Embodiment 3: Embodiment of the present embodiment and the exemplary embodiment a one or two points are different: The method of preparing the graphene based conductive asphalt layer 2 as follows:

[0052] First, in parts by weight from 5 parts to 10 parts asphalt, 70 parts to 120 parts of aggregate and 15 to 20 parts ore; the modified asphalt, aggregate and carbon fibers stirred at 170 ℃ ~ 175 ℃ 3min ~ 5min, and then added with stirring slag 2min ~ 3min, to give early mixing;

[0053] Second, a conductive shape memory composites and graphite-modified alkylene oxide is added to the beginning of the mixing, and then stirred at 155 ℃ ~ 165 ℃ 2min ~ 3min, using Marshall compaction method, to obtain graphene based conductive layer of the asphalt 2. Other specific embodiments of a step or two identical.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com