Corrugated energy absorption structure

An energy-absorbing structure and corrugated technology, applied in the field of energy-absorbing, can solve the problems of unsatisfactory initial stiffness energy absorption and low buffering capacity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

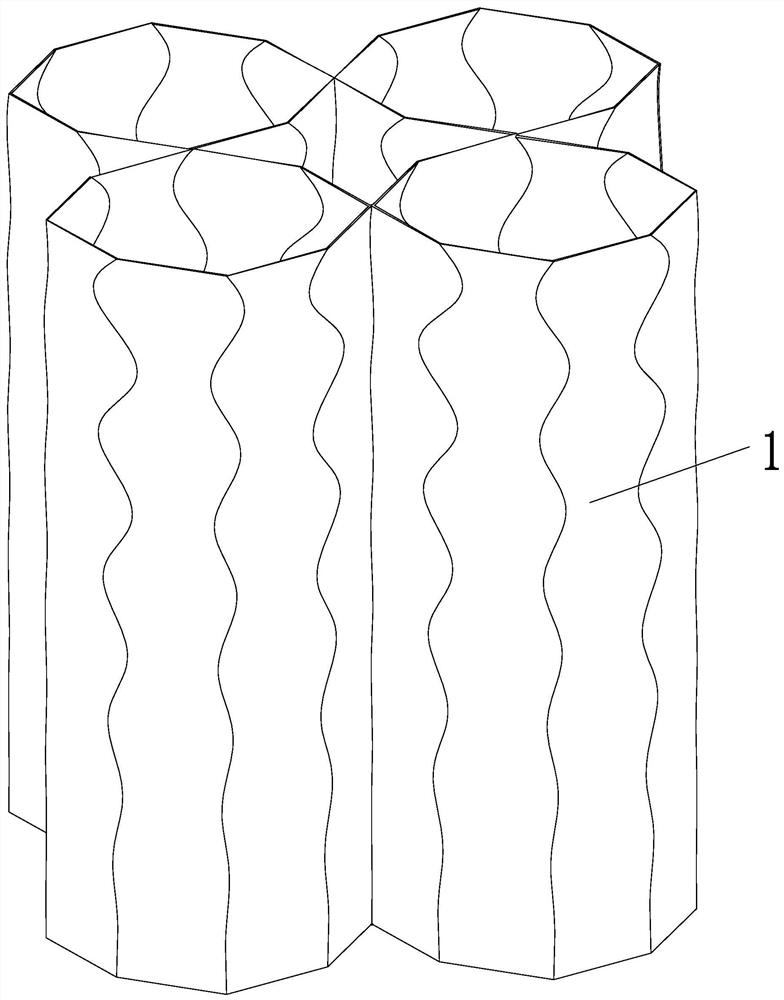

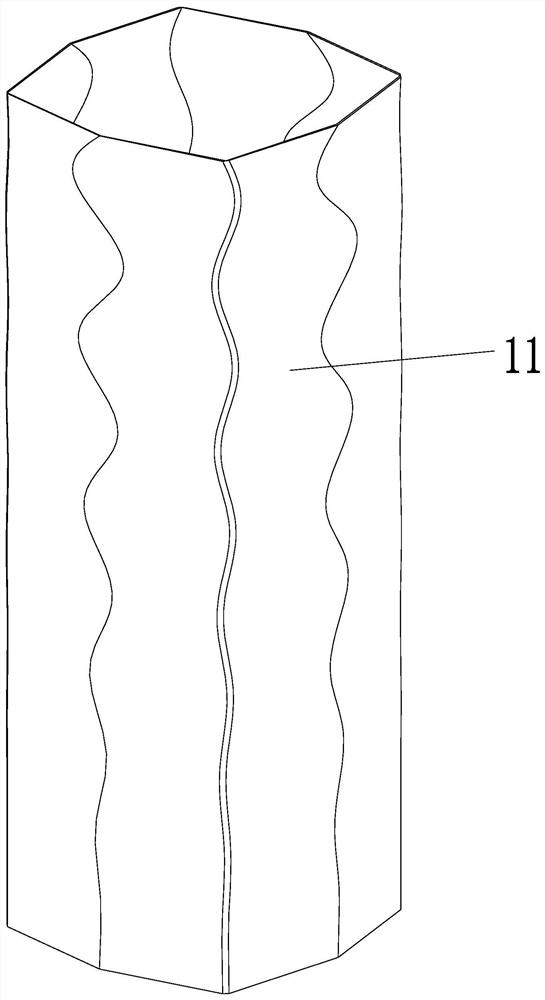

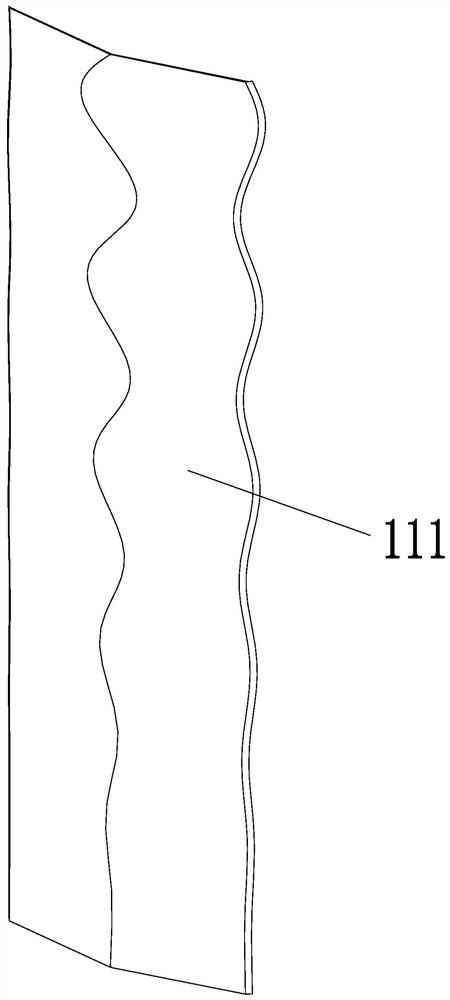

[0027] A corrugated energy-absorbing structure, refer to Figures 1 to 8 , including a plurality of energy-absorbing columns 1, so that the entire energy-absorbing structure can have sufficient deformation and crushing space in the process of being crushed by a collision, and each energy-absorbing column 1 adopts the same height h to ensure Most of the energy-absorbing columns 1 can produce energy-absorbing effects at the same time. The energy-absorbing column 1 is formed by splicing two corrugated units 11; the corrugated unit 11 is formed by splicing two corrugated sheets 111; Including straight lines arranged on the upper and lower sides; between the two straight sides is a corrugated curved surface, the side view of the curved surface is a curve, and the curve satisfies

[0028]

[0029] Among them, the x direction is parallel to the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com