Rapid demolding device for preventing cracks in constant-temperature glass pouring

A demolding device, glass technology, used in glass forming, glass pressing, glass manufacturing equipment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments. Wherein the same components are denoted by the same reference numerals. It should be noted that the words "front", "rear", "left", "right", "upper" and "lower" used in the following description refer to the directions in the drawings, and the words "bottom" and "top ”, “inner” and “outer” refer to directions toward or away from the geometric center of a particular part, respectively.

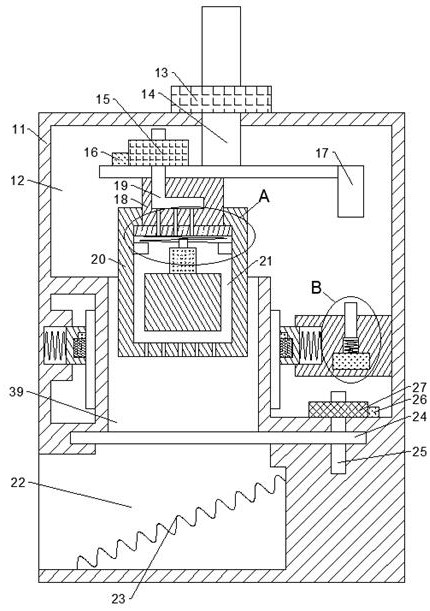

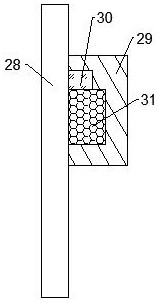

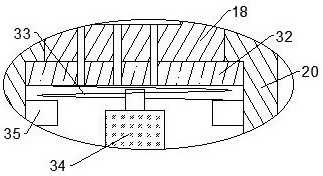

[0018] Such as Figures 1 to 4 As shown, a constant temperature pouring glass prevents cracks from quickly demoulding device, including an injection molding box 11, which is provided with a pouring cavity 12 in the injection molding box 11, and a hydraulic press 13 is fixedly connected to the injection molding box 11. The hydraulic press 13 is slidably connected with a preliminary molding device for providing press modeling for the device, the injection molding ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com