Stock bin discharging port shutoff valve for powder filling isostatic pressing forming die

A technology of isostatic pressing and material outlet, which is applied in the field of cut-off valve at the material outlet of the silo, can solve the problems of powder consumption and waste, increase the operation process of cleaning and spilling powder, and the remaining material is easy to overflow and leak, so as to overcome the dust Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

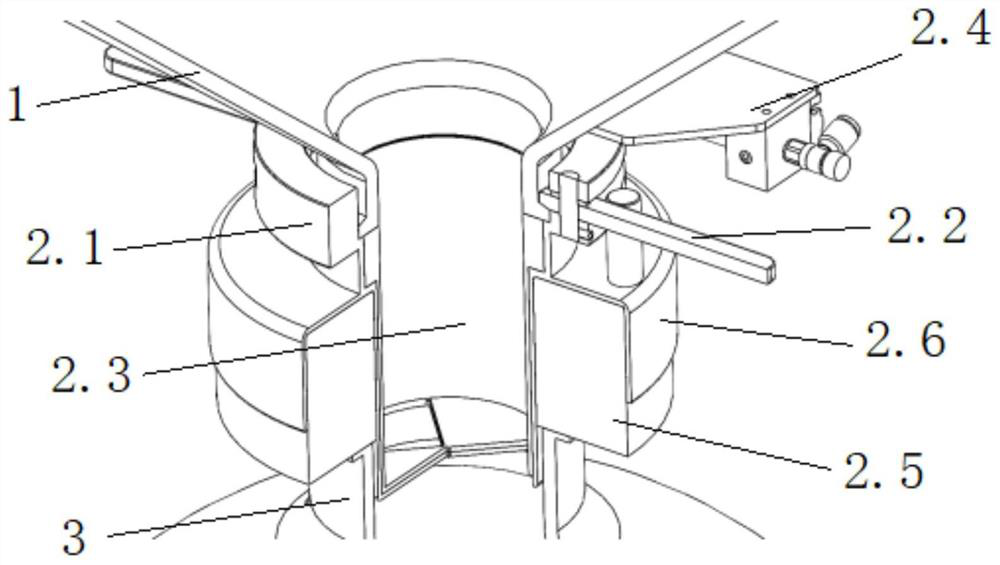

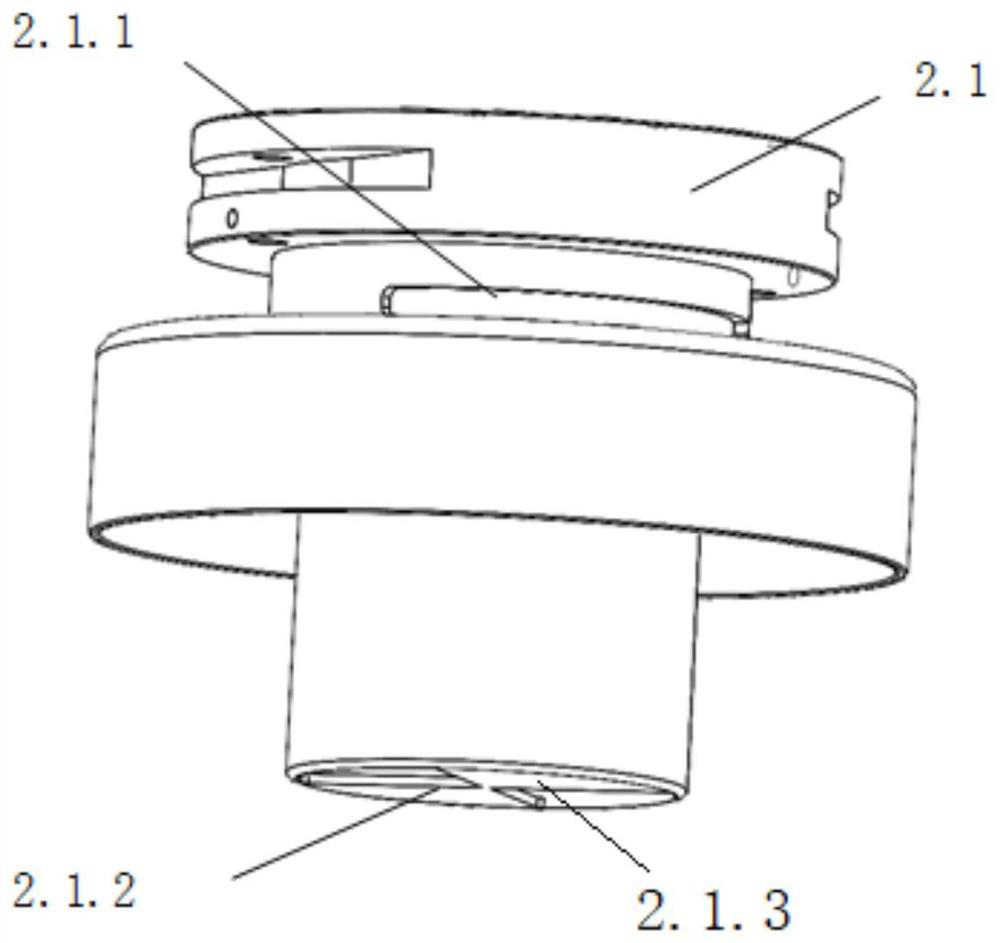

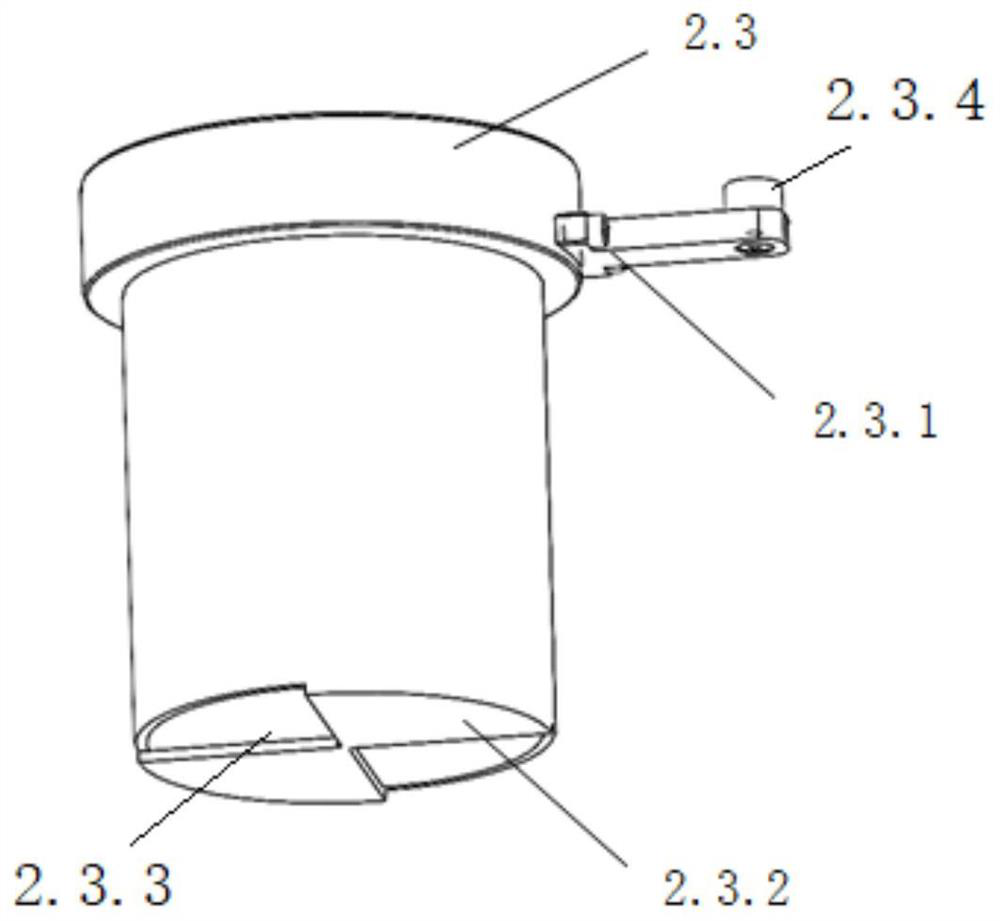

[0019] Such as figure 1 As shown, a shut-off valve at the discharge port of the silo used for filling the isostatic molding mold with powder includes a silo 1 and a shut-off valve. The shut-off valve includes a valve body 2.1, a locking switch 2.2, a valve core 2.3, The driving part, the valve body 2.1 is connected to the outlet of the material bin 1 through the lock switch 2.2, the valve core 2.3 is rotated and set in the valve body 2.1 through the driving part, and the bottom of the valve body 2.1 is provided with the valve body 2.1 blanking baffle and The valve body 2.1 feed opening, the valve core 2.3 is provided with a cavity connected with the discharge port of the material bin 1, the bottom of the cavity is provided with the valve core 2.3 feed baffle and the valve core 2.3 feed opening, the valve core 2.3 Driven by the driving part, the spool 2.3 blanking baffle can close or open the valve body 2.1 blanking port.

[0020] The shut-off valve of the present invention is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com