Automatic compensation filling device for isostatic press moulding of energetic materials

An isostatic pressing forming and automatic compensation technology, which is applied in the field of energetic materials, can solve the problems of adverse effects on subsequent forming performance, increase the operation process of cleaning and spraying, and damage the physical and mental health of operators, so as to improve the level of intrinsic safety and occupational hygiene , improve quality consistency and production efficiency, and overcome the effect of high labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

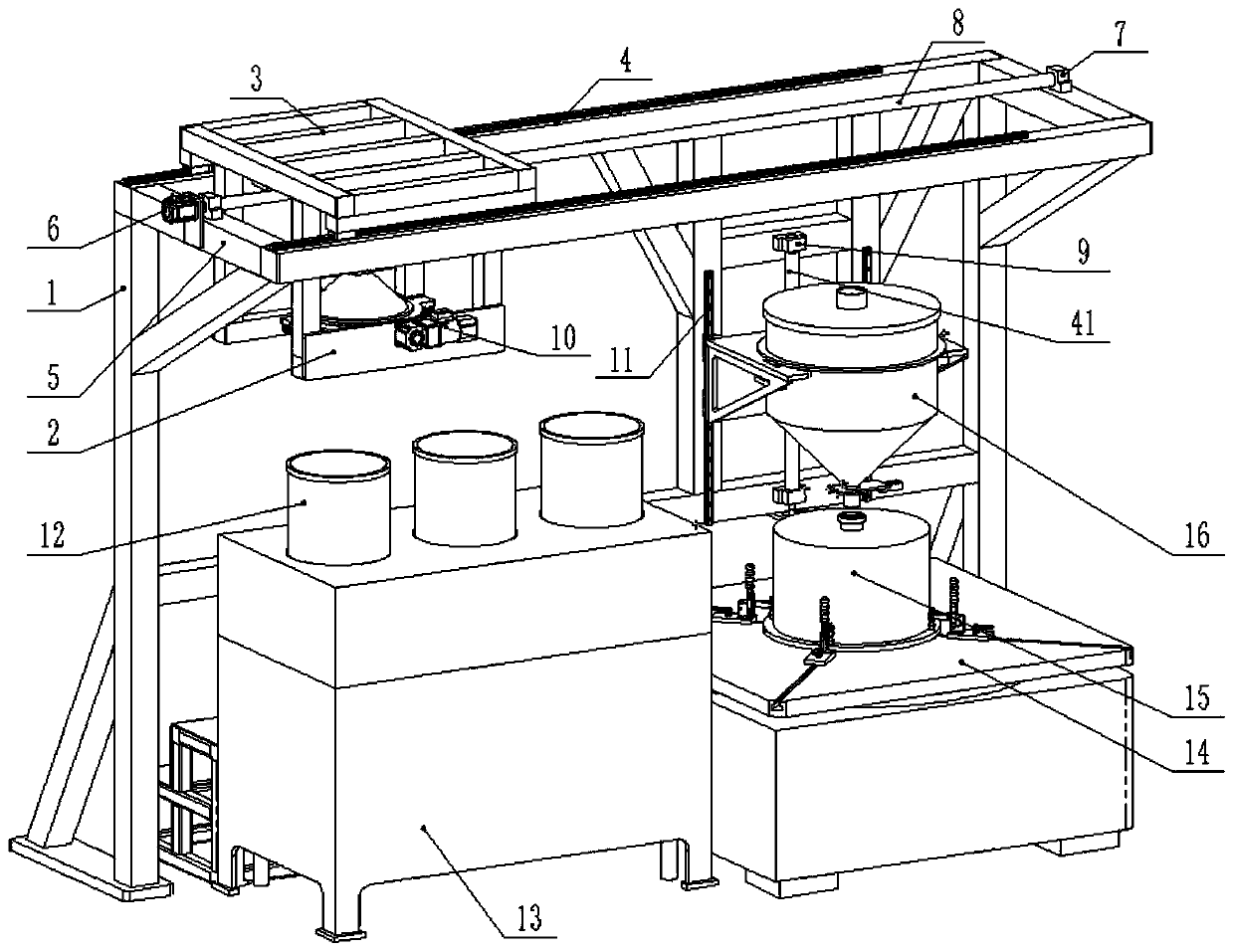

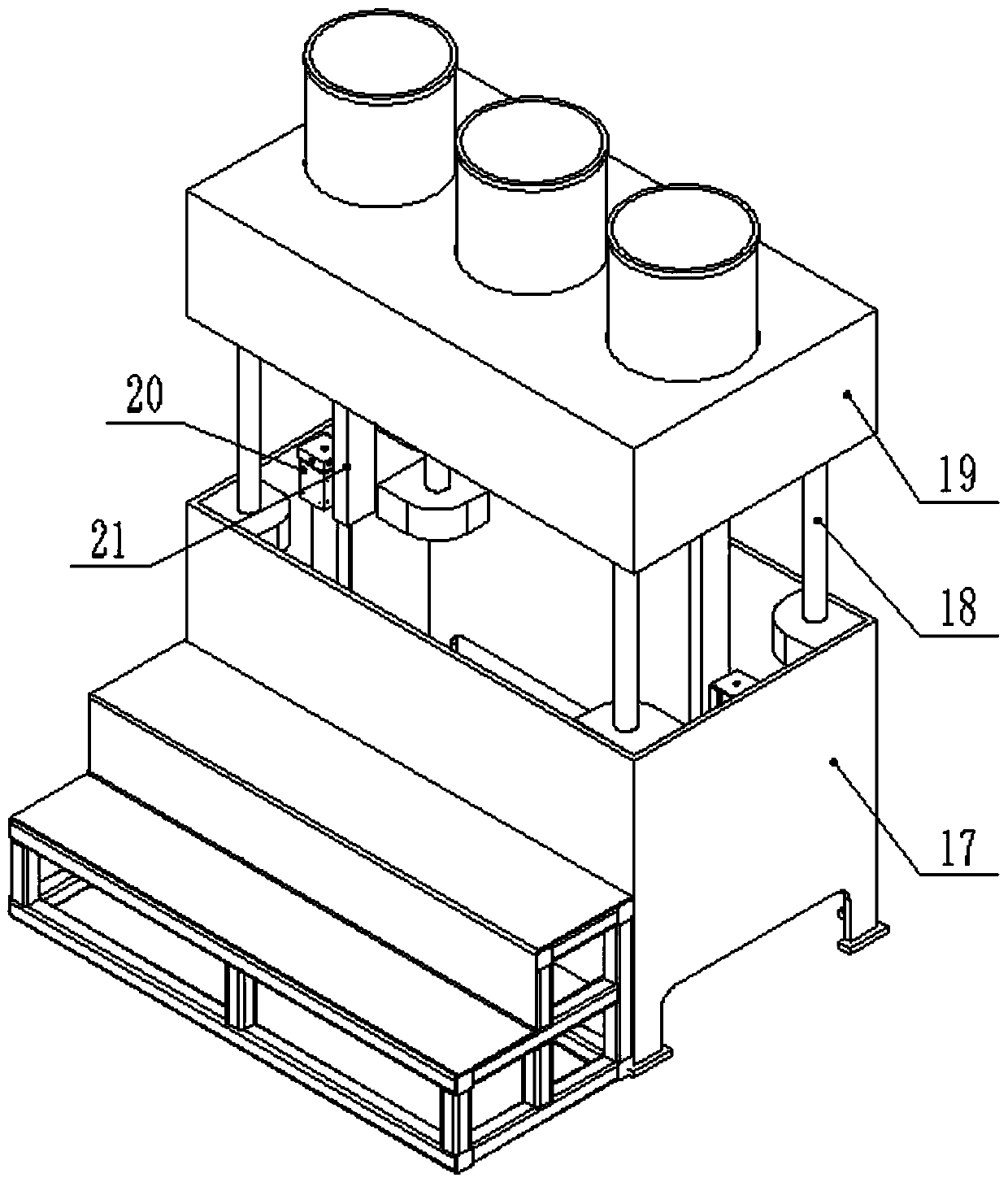

[0034] Such as Figure 1-9 As shown, an automatic compensation filling device for isostatic pressing of energetic materials, including a frame 1, a barrel gripper assembly, a lifting table assembly 13, a barrel 12, an elevating hopper assembly, a hopper 16, and an elastic mold 15 and the vibrating table 14, the frame 1 is used as the overall support and positioning of the system, and the lower bottom plate is fixed to the ground; the barrel 12 is used to store energetic material powder raw materials. The hopper 16 is used for the temporary storage and automatic feeding of energetic material powder, which can move up and down, and an automatic slide valve 32 is installed at the bottom. The lifting table assembly 13 and the vibrating table 14 are installed in one side of the frame 1, the barrel 12 is placed on the upper part of the lifting table assembly 13, the elastic mold 15 is installed on the vibrating table 14, and the elevating hopper assembly is slidably installed on the...

Embodiment 2

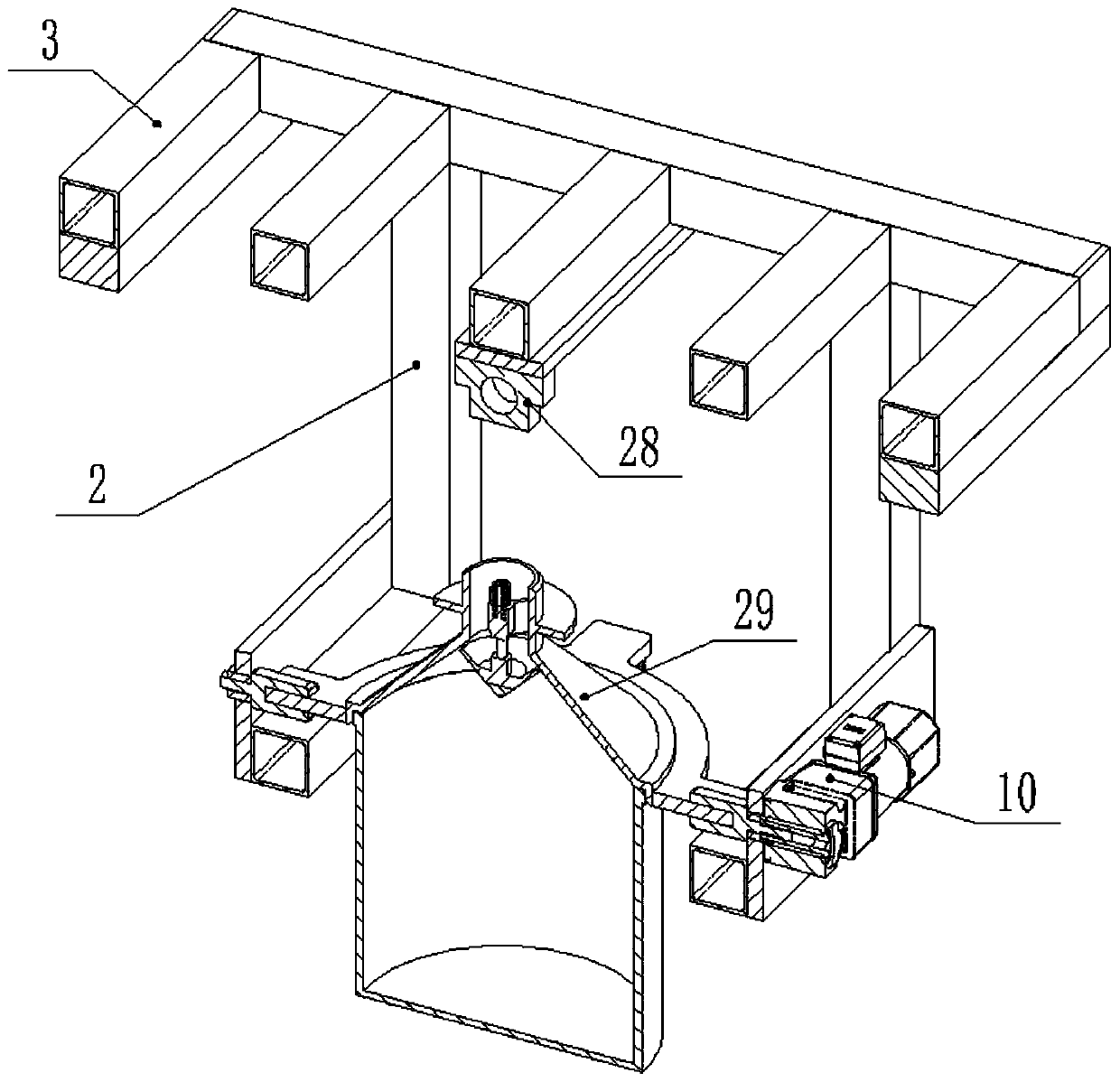

[0037] Such as image 3 As shown, this embodiment is further optimized on the basis of Embodiment 1, and the similarities will not be repeated. In this embodiment, the barrel gripper assembly includes a first displacement assembly, a first mounting frame, a material The barrel positioning plate 22, the claw assembly and the sealing cover 29, the first displacement assembly is installed on the top of the frame 1, the first installation frame is movably installed on the first displacement assembly, the barrel positioning plate 22 is circular, and the barrel The inner ring of the positioning plate 22 is used to fasten on the barrel 12, and the barrel positioning plate 22 is equipped with two oppositely arranged gripper assemblies for grabbing the barrel 12 and two oppositely arranged gripper assemblies for driving the barrel 12. The rotating shaft 23 turned over by the positioning plate 22, the connection line between the two claw assemblies and the two rotating shafts 23 is a cr...

Embodiment 3

[0041] Such as Figure 4 As shown, this embodiment is further optimized on the basis of Embodiment 2, and the similarities will not be repeated. In this embodiment, the claw assembly includes a cylinder 24, an arc matched with the side wall of the barrel 12 Shaped pressure head 25 and anti-static rubber pad 26, cylinder 24 is installed on the bottom of barrel positioning plate 22, arc-shaped pressure head 25 is installed on the telescopic rod of cylinder 24, anti-static rubber pad 26 is installed on the arc-shaped pressure head 25 . This embodiment mainly provides the specific structure of the holding claw assembly. The arc-shaped pressure head 25 expands and contracts under the action of the cylinder 24 to complete the holding and fixing of the barrel 12. And anti-static rubber pad 26 one is to play the effect of anti-static, plays the effect of safety, the 2nd, can make arc-shaped indenter 25 and barrel 12 side walls fasten more closely, contributes to the hugging of barrel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com