Rotary feeding device capable of improving tobacco shred dipping uniformity and distribution method

A feeding device and rotary feeding technology, used in loading/unloading, transportation and packaging, conveyors, etc., can solve the problems of hidden safety hazards, difficult to solve the problem of stacking compactness, and high labor intensity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

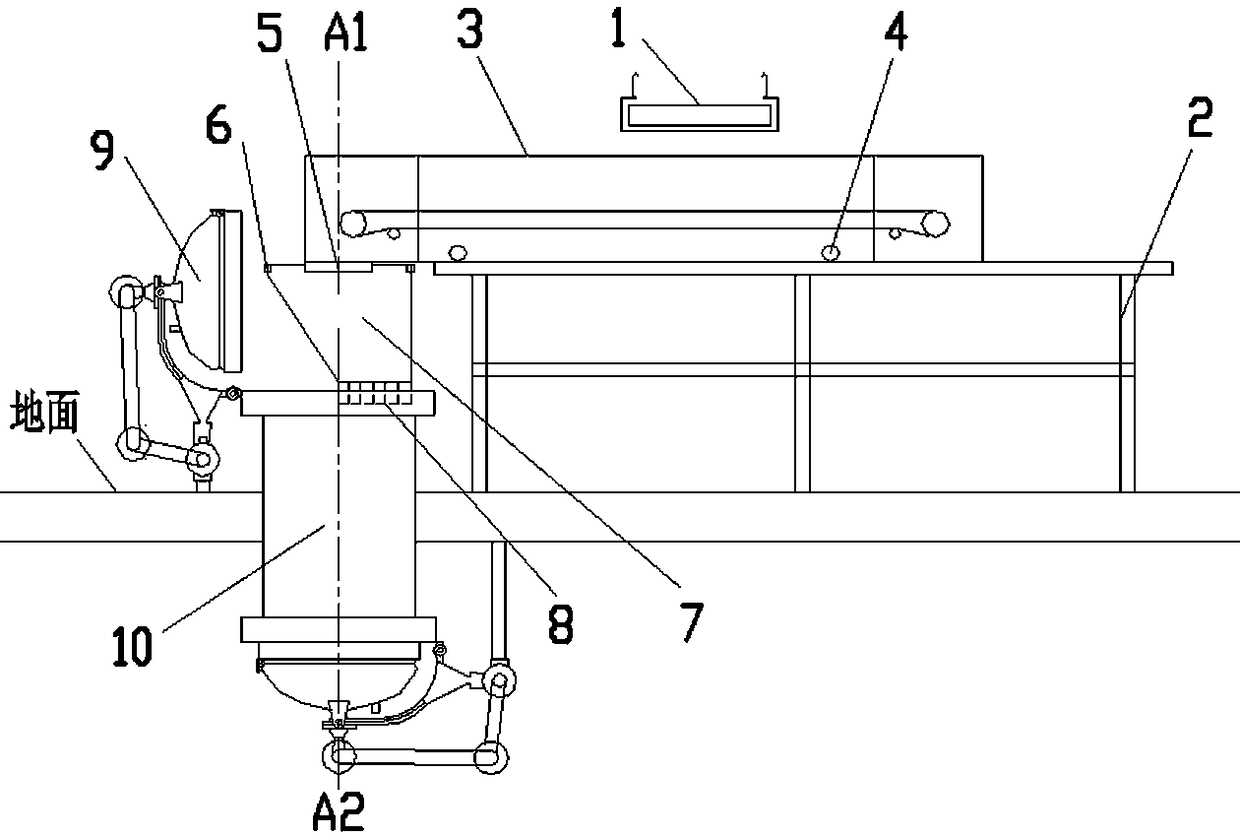

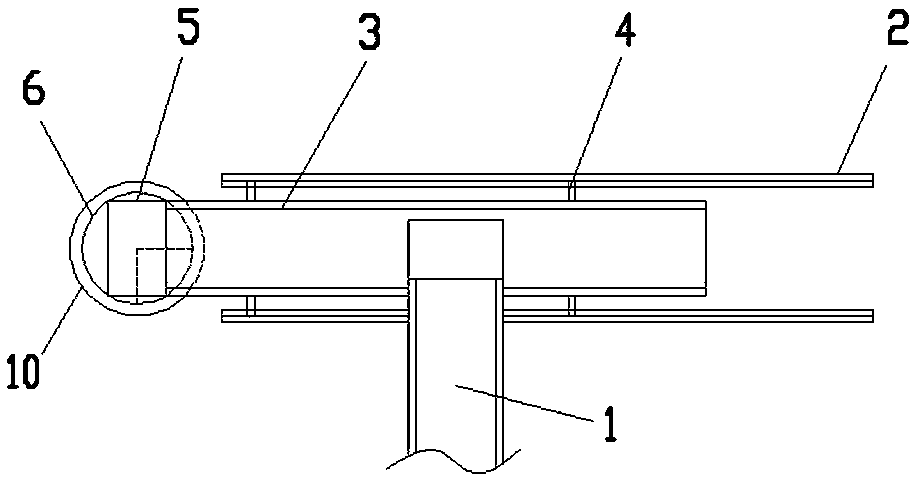

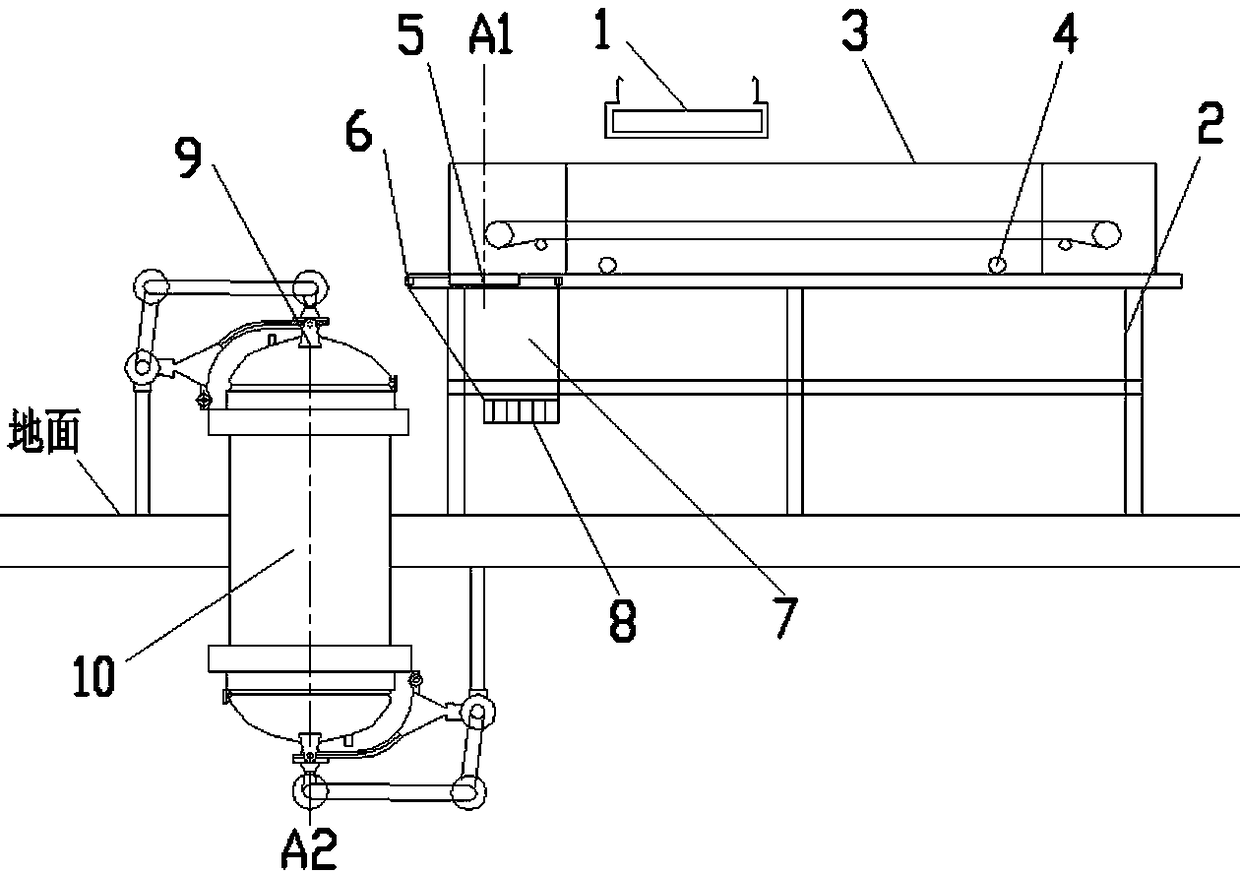

[0021] In order to describe the technical content, purpose and effect of the present invention in detail, the following will be further described in conjunction with the schematic diagram of the rotary feeding device and examples, but the embodiments of the present invention are not limited thereto:

[0022] Such as Figure 1-5 Shown: a rotary feeding device for improving the uniformity of impregnation of shredded tobacco, including a cloth belt conveyor 3 and a rotary feeder arranged below the outlet 5 of the cloth belt conveyor, the rotary feeder is used to feed the impregnator tank 10 for distributing, wherein: a forward and backward moving mechanism 4 is installed under the cloth belt conveyor 3, which can drive the belt conveyor to move back and forth relative to the position of the impregnator; the rotary feeder is composed of a rotating mechanism 6 fixed at the outlet 5 of the belt conveyor and The feeder 7 connected to the rotating mechanism is composed of a feeder 7 d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com