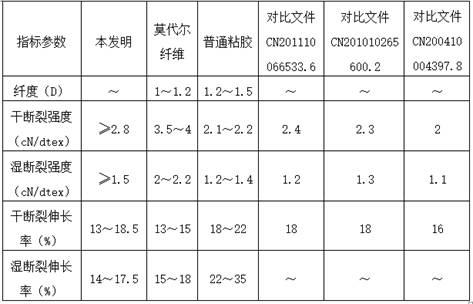

A kind of hemp high-strength regenerated cellulose fiber and its production method

A technology of regenerated cellulose and cellulose fibers, applied in fiber processing, fiber chemical characteristics, wet spinning, etc., can solve problems such as unsuitability for large-scale production and unsatisfactory indicators such as hemp regenerated cellulose fibers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

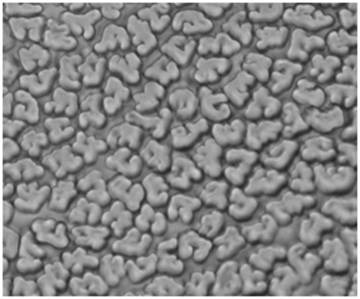

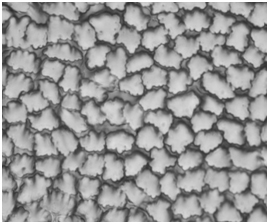

Image

Examples

Embodiment 1

[0048] A preparation process of hemp high-strength regenerated cellulose fiber comprises the following steps:

[0049] Using hemp pulp as raw material, the spun viscose is prepared through steps including secondary dipping, aging, dissolving and spinning;

[0050] 1. Second impregnation: The alkali cellulose after the first impregnation is impregnated twice; during the second impregnation, the concentration of NaOH impregnation solution is 165g / L, the impregnation temperature is 40°C, and the impregnation time is 45 minutes. The auxiliary agent LV-3 is added during the impregnation process. The amount of the auxiliary agent (relative to the methyl fiber in the alkali cellulose) is: 0.03%. After the second impregnation, the alkali cellulose composition is: the methyl fiber content is 29wt%, and the NaOH content is 13wt. %.

[0051] 2. Aging: The aging temperature is 15°C, the time is 10 hours, and the viscosity of copper ammonia at the outlet of the aging is controlled to 70mP...

Embodiment 2

[0056] A preparation process of hemp high-strength regenerated cellulose fiber comprises the following steps:

[0057] Using hemp pulp as raw material, the spun viscose is prepared through steps including secondary dipping, aging, dissolving and spinning;

[0058] 1. Second impregnation: the alkali cellulose after the first impregnation is impregnated twice; during the second impregnation, the concentration of NaOH impregnation solution is 178g / L, the impregnation temperature is 45°C, and the impregnation time is 40 minutes. The auxiliary agent LV-3 is added during the impregnation process, and the amount of the auxiliary agent (relative to the methyl fiber in the alkali cellulose) is: 0.05%. After the second impregnation, the alkali cellulose composition is: the methyl fiber content is 30wt%, and the NaOH content is 12wt%. .

[0059] 2. Aging: the aging temperature is 20°C, the time is 7 hours, and the viscosity of copper ammonia at the outlet of the aging is controlled to 7...

Embodiment 3

[0064] A preparation process of hemp high-strength regenerated cellulose fiber comprises the following steps:

[0065] Using hemp pulp as raw material, the spun viscose is prepared through steps including secondary dipping, aging, dissolving and spinning;

[0066] 1. Second impregnation: the alkali cellulose after the first impregnation is impregnated twice; during the second impregnation, the concentration of NaOH impregnation solution is 183g / L, the impregnation temperature is 48°C, and the impregnation time is 35 minutes. The auxiliary agent LV-3 is added during the impregnation process. The amount of the auxiliary agent (relative to the methyl fiber in the alkali cellulose) is: 0.07%. After the second impregnation, the alkali cellulose composition is: the methyl fiber content is 31wt%, and the NaOH content is 12wt. %.

[0067] 2. Aging: the aging temperature is 25°C, the time is 6 hours, and the viscosity of copper ammonia at the outlet of the aging is controlled to be 78...

PUM

| Property | Measurement | Unit |

|---|---|---|

| breaking strength | aaaaa | aaaaa |

| breaking strength | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com