Internal infrared indirect heating equipment, catalyst impregnation method and catalyst preparation method

A heating equipment, infrared heating technology, applied in the field of internal infrared indirect heating equipment, catalyst preparation, catalyst impregnation, to extend the operating period, reduce erosion, reduce adhesion effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0049] In a third aspect, the present invention provides a method for preparing a catalyst, the method comprising: impregnating the catalyst carrier with a molten solution of a crystalline salt of an active metal component, and then roasting the obtained impregnated material, the impregnated method according to the present invention The catalyst impregnation method described in the invention is carried out.

[0050] In the preparation method of the catalyst of the present invention, no additional water is introduced, so no drying process is required.

[0051] In the preparation method of the catalyst of the present invention, there is no special limitation on the calcination conditions, which can be various conditions commonly used in this field. Preferably, the calcination conditions include: temperature of 500-700° C., time of 1-10 h.

Embodiment 1

[0061] This embodiment is used to illustrate the internal infrared indirect heating equipment, the impregnation method of the catalyst and the preparation method of the catalyst of the present invention.

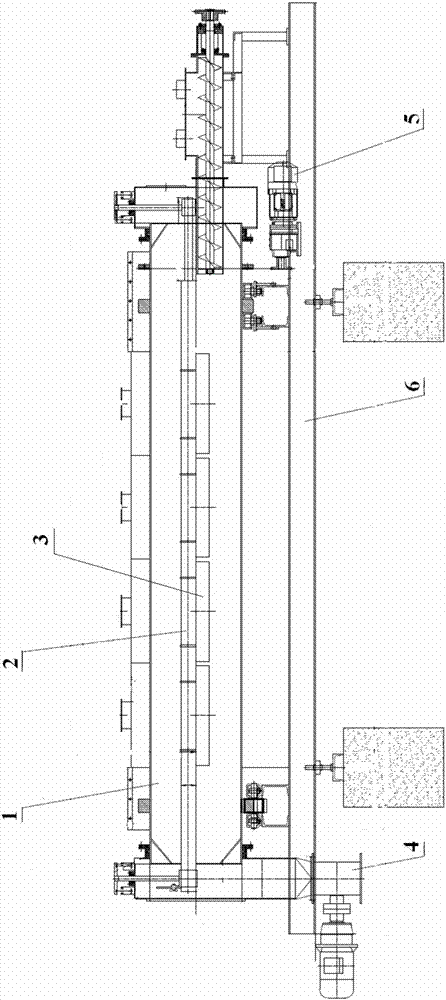

[0062] Such as figure 1 As shown, the internal infrared indirect heating equipment of this embodiment includes a feed mixing device, a drum turning device, an infrared heating device, a temperature control device and a discharge device,

[0063] Among them, the drum turning device is used to mix the materials placed in the drum, including the drum 1, the elevation angle adjustable bracket 6 and the gear motor 5, the drum 1 is a stainless steel drum, the inner diameter is 550mm, the outer diameter is 556mm, and the length is 4035mm; the elevation angle adjustable bracket 6 is used to adjust the elevation angle of the drum 1, and the geared motor 5 is used to control the rotation speed of the drum 1;

[0064] Wherein, the feed mixing device is used to mix the catalyst carrier...

Embodiment 2

[0077] Using the equipment of Example 1 and according to the method of Example 1, the difference is that in the infrared heating device, the central axis of the support is higher than the central axis of the rotating drum, and the vertical distance between the central axis of the support and the central axis of the rotating drum Distance is 4% of rotating cylinder diameter; In the method, the feeding speed of controlling catalyst carrier and nickel nitrate crystal is 120.5kg / h and 121.3kg / h respectively, and the feeding speed of controlling mixed material is 245kg / h; Adjust rotating drum The rotation speed of the rotary drum is 2.0 rpm, the elevation angle of the drum is 1.7°, and the residence time of the mixed material in the drum is controlled to be 22 minutes; the input power of the infrared heating plate is adjusted so that the temperature of the atmosphere in the drum is 73°C, controlled by the fan The temperature of the outer wall of the drum was 58°C.

[0078] A total ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com