Method for preparing 2D resin-sodium silicate compositely-enhanced poplar

A composite reinforcement and sodium silicate technology, applied in wood impregnation, wood treatment, impregnated wood, etc., can solve the problems of flammable and perishable application range, poor dimensional stability, low mechanical strength, etc., to ensure organic cross-linking reaction, The effect of low equipment requirements and high reaction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

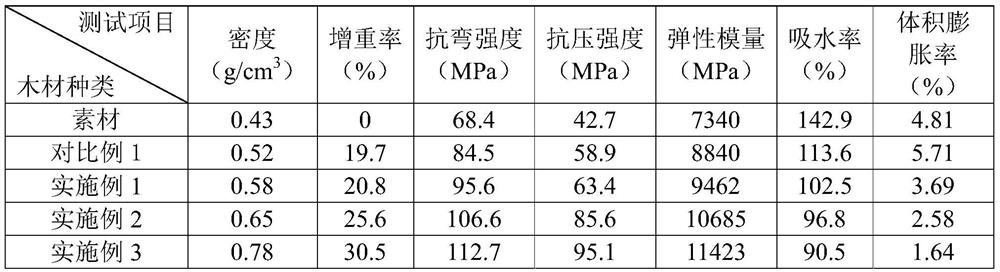

Embodiment 1

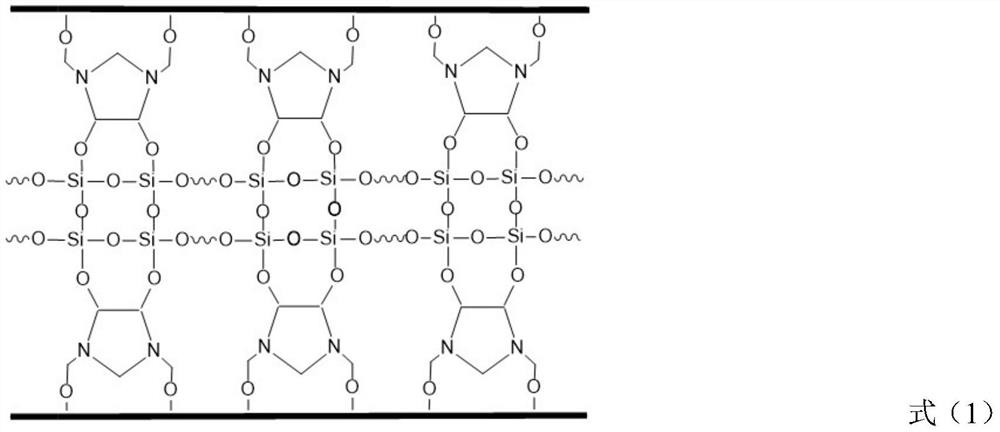

[0027] A 2D resin-sodium silicate composite reinforcing method for poplar wood of the present invention is to first chemically combine the 2D resin with the wood cell wall through the method of negative pressure-positive pressure alternating cycle impregnation, and then impregnate the sodium silicate into the wood. , the sodium silicate reacts and combines with the 2D resin attached to the cell wall to form a physical and chemical joint filling, and the 2D resin-sodium silicate composite reinforced poplar is obtained. The specific test process includes the following steps:

[0028] (1) Pretreatment of poplar wood: The poplar wood is sawed according to specifications: length×width×height is 60mm×60mm×300mm, and the poplar wood is dried to a moisture content of 5%.

[0029] (2) Immerse the 2D resin into poplar wood by dipping: prepare 5000 g of an aqueous solution of 4% 2D resin according to the formula, then put the poplar wood in a closed tank, first vacuum to -0.05MPa and kee...

Embodiment 2

[0033] A method for 2D resin-sodium silicate composite reinforcement of poplar wood is to chemically combine the 2D resin with the wood cell wall through the method of alternating negative pressure-positive pressure impregnation, and then impregnate the sodium silicate into the wood to make the silicon The sodium reacted and combined with the 2D resin attached to the cell wall to form a physicochemical joint filling to obtain a 2D resin-sodium silicate composite reinforced poplar. The specific test process includes the following steps:

[0034] (1) Pretreatment of poplar wood: The poplar wood is sawed according to specifications: length×width×height is 60mm×60mm×300mm, and the poplar wood is dried to a moisture content of 7%.

[0035] (2) Immerse the 2D resin into poplar wood by dipping: according to the formula, prepare 5000g of 2D resin solution with a mass fraction of 6%, then put the poplar wood in a closed tank, first vacuumize to -0.07MPa and keep the pressure for 20min,...

Embodiment 3

[0039] A method for 2D resin-sodium silicate composite reinforcement of poplar wood is to chemically combine the 2D resin with the wood cell wall through the method of alternating negative pressure-positive pressure impregnation, and then impregnate the sodium silicate into the wood to make the silicon The sodium reacted and combined with the 2D resin attached to the cell wall to form a physicochemical joint filling to obtain a 2D resin-sodium silicate composite reinforced poplar. The specific test process includes the following steps:

[0040] (1) Pretreatment of poplar wood: The poplar wood is sawed according to the specifications: length×width×height is 60mm×60mm×300mm, and the poplar wood is dried to a moisture content of 9%.

[0041] (2) Immerse the 2D resin into poplar wood by dipping: according to the formula, prepare 5000g of 2D resin solution with a mass fraction of 8%, then put the poplar wood in a closed tank, first vacuum to -0.09MPa and keep the pressure for 30min...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com